Fringe Operator gives you real time data you can trust.

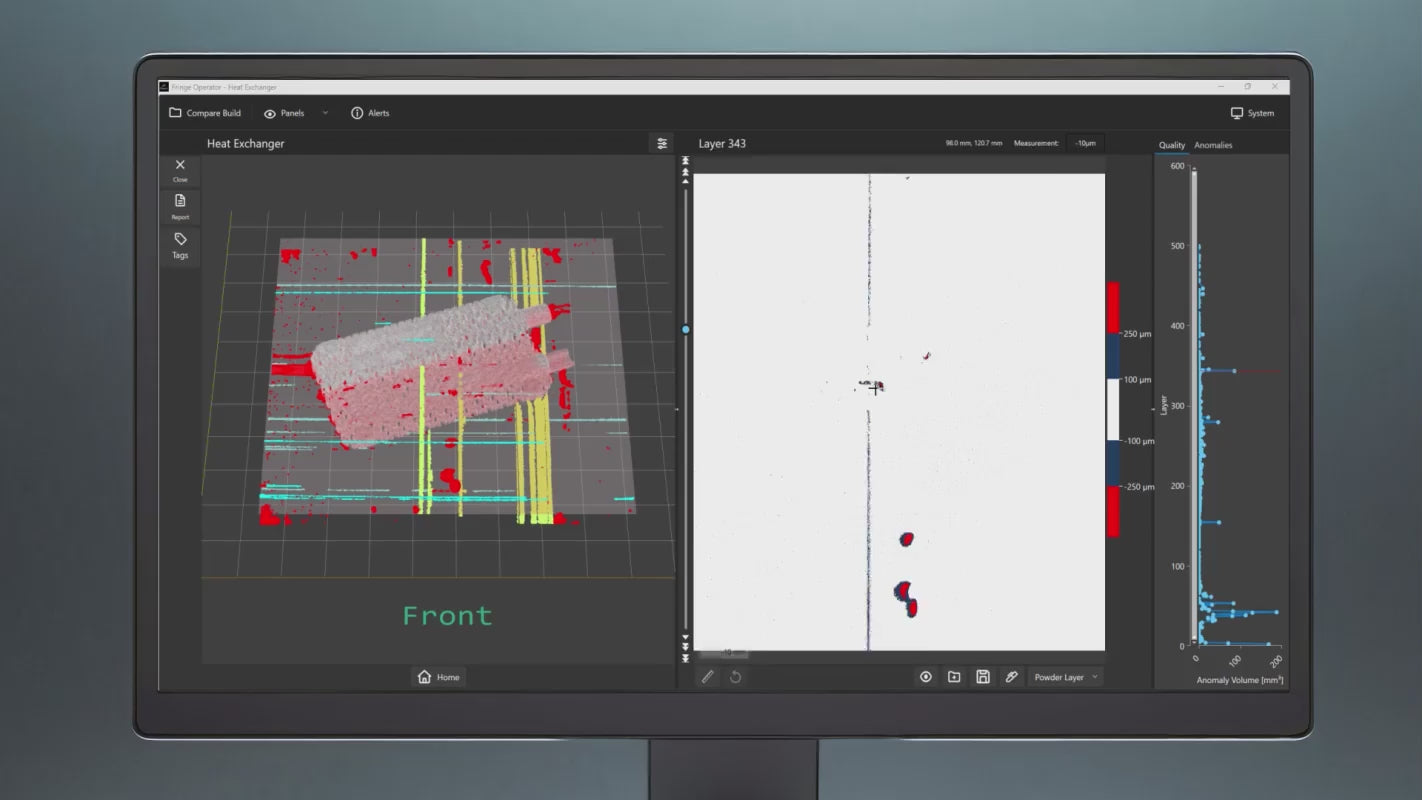

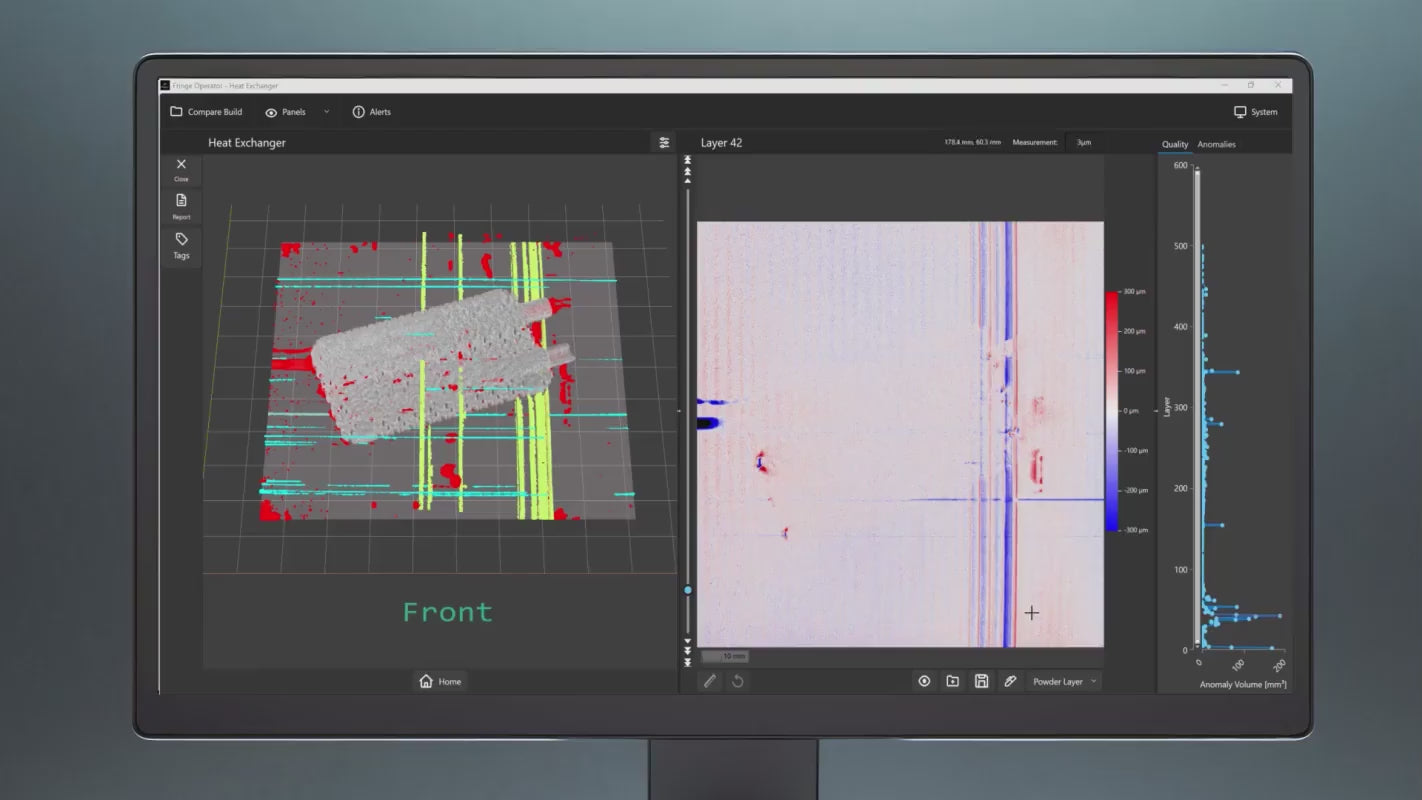

Fringe Operator is the interactive visualization and analytics tool within Fringe Inspection. It is purpose-built for engineers, process developers, and technicians who need precise, real-time insights into every layer of the build.

Fringe Operator gives users a digital twin and the ability to see, measure, and make decisions on anomalies that fail builds in real-time.

What to Know about Fringe Operator

Layer-by-Layer Visualization & Deep Dive Analytics

Whether optimizing a new geometry, dialing in parameters, or monitoring production builds, Fringe Operator provides the inspection-level clarity required to:

- Perform root cause analysis on first-build failures

- Identify part protrusions, recoater streaks, short feeds, and spatter

- Measure internal wall thickness and feature shapes

- Validate build consistency and ensure process repeatability heightmaps

- Compare current builds to pass/fail benchmarks

- Load data from any modality to compare against Fringe Inspection heightmaps

A Tool For Every Shop Floor

Watch our latest webinar to learn more about how Fringe Operator is used and how it can support your printing - from product development to production.