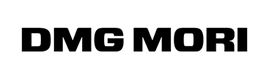

Fringe Inspection™ Identifies Problems Immediately

Additive Manufacturing has a problem – defective parts are not identified until a significant amount of time and money are invested into the part. Fringe Inspection identifies defects as they occur, reducing waste from days to hours.

Fringe Inspection is Scalable

Phase3D's system can be added to most industrial metal additive manufacturing systems.

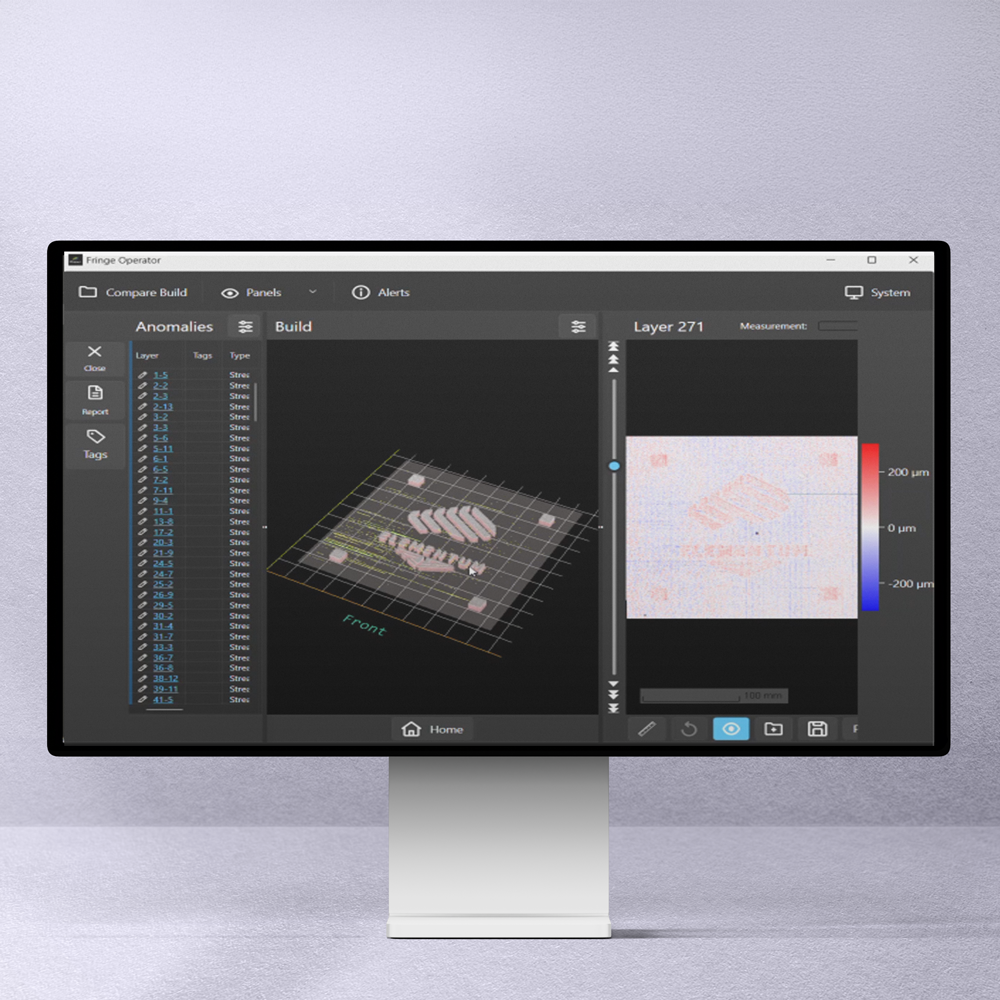

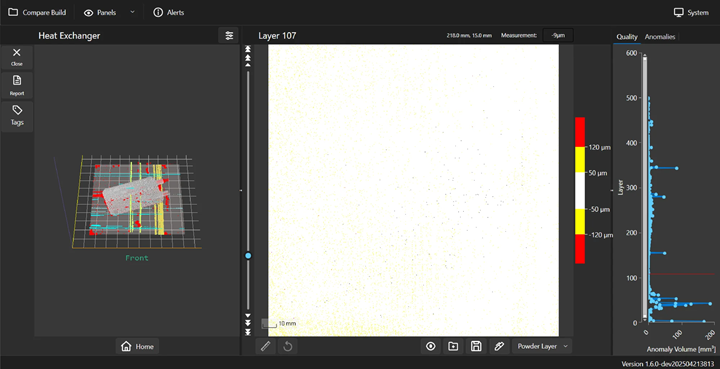

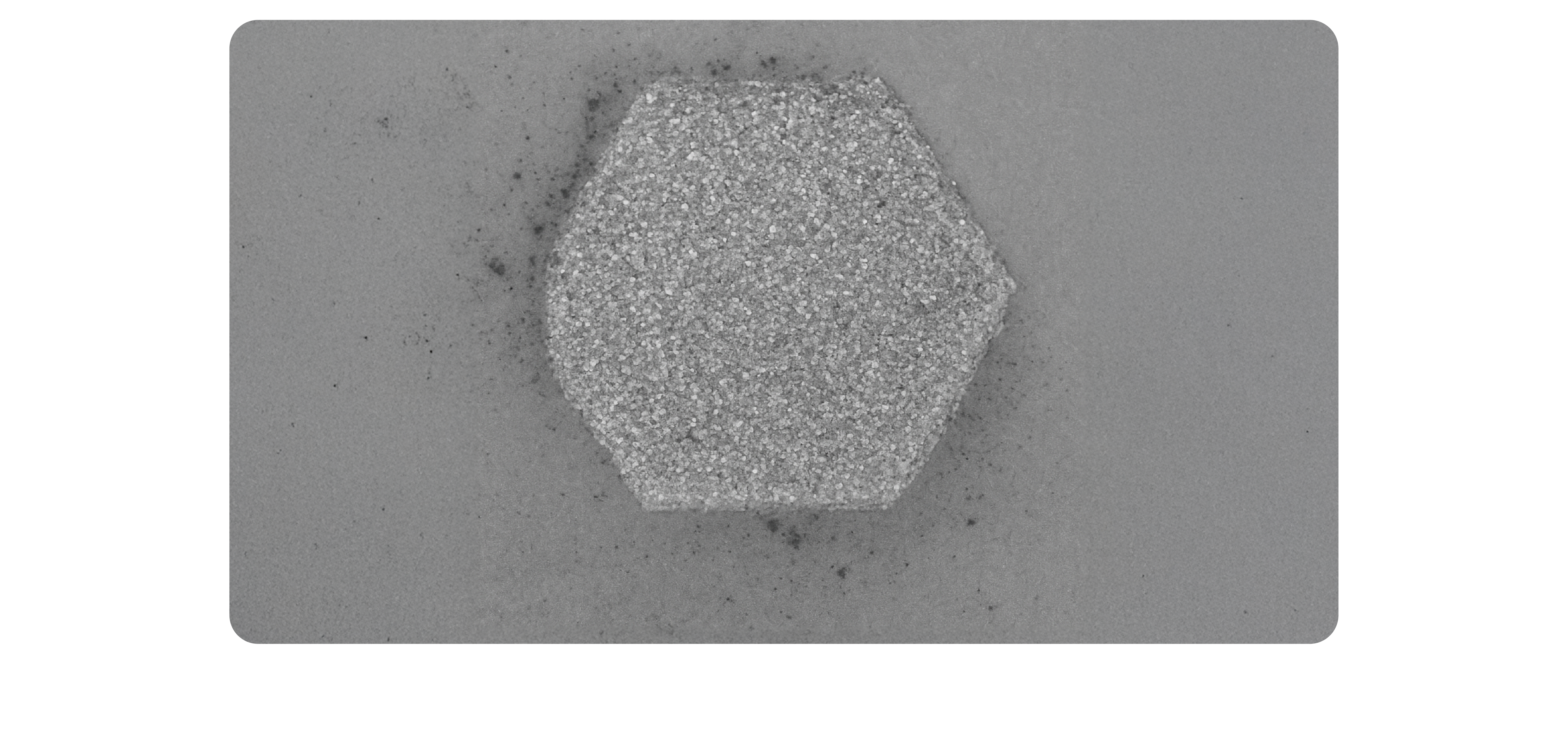

Measure, Identify & Improve AM Using Objective Data

Fringe Inspection Measures. Stop Just Looking.

Camera Image

Measurements with Phase3D