Fringe Projection for Real-Time Metal Additive Manufacturing Inspection

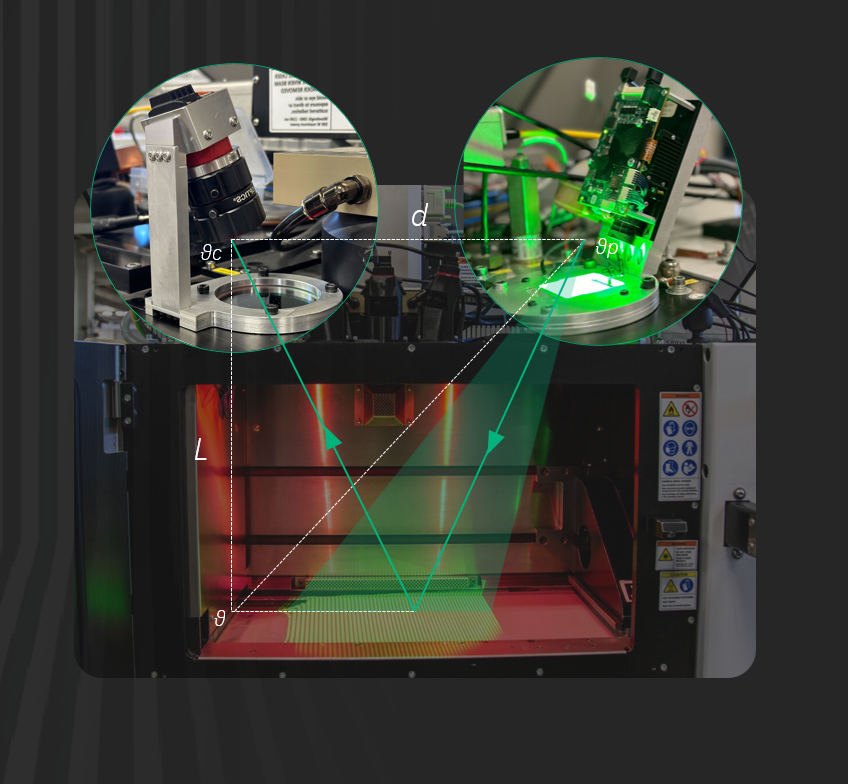

Fringe Inspection is built upon the core principal of measuring what you want to detect. The system uses digital fringe projection (DFP), a subset of structured light, to measure the surface of the powder-based metal additive manufacturing (AM) process. The entire build area is measured for every layer with micron-level precision.

Unlike traditional camera-based detection methods that rely on shadows, artificial intelligence, or machine learning analysis, Fringe Inspection includes a projector assembly that displays a known pattern of light onto the build area. The camera then captures distortions of the pattern across the surface caused by anomalies.

Fringe projection applied to AM enables real-time detection, classification, and labeling of anomalies from the build process for scientifically backed decision making.

Compatible With

Fringe Inspection in Action

Fringe Inspection is compatible with most industrial powder-based metal 3D printers, including powder bed fusion (PBF), binder jetting (BJT), and cold spray. Installing Fringe Inspection does not impact the build process or machine's performance.

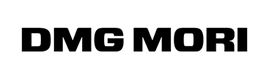

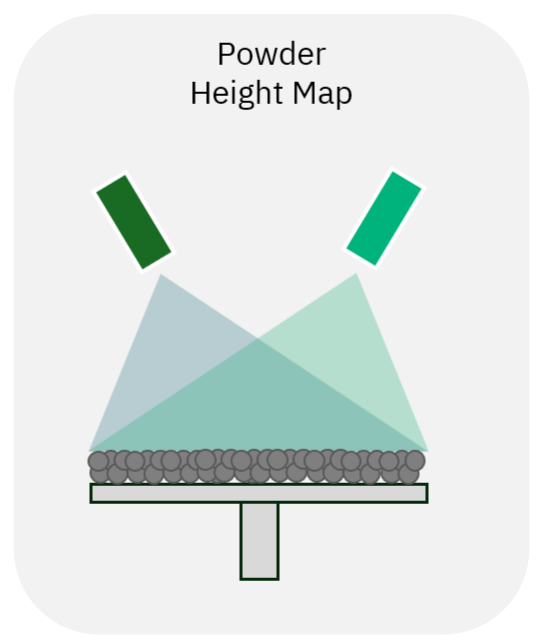

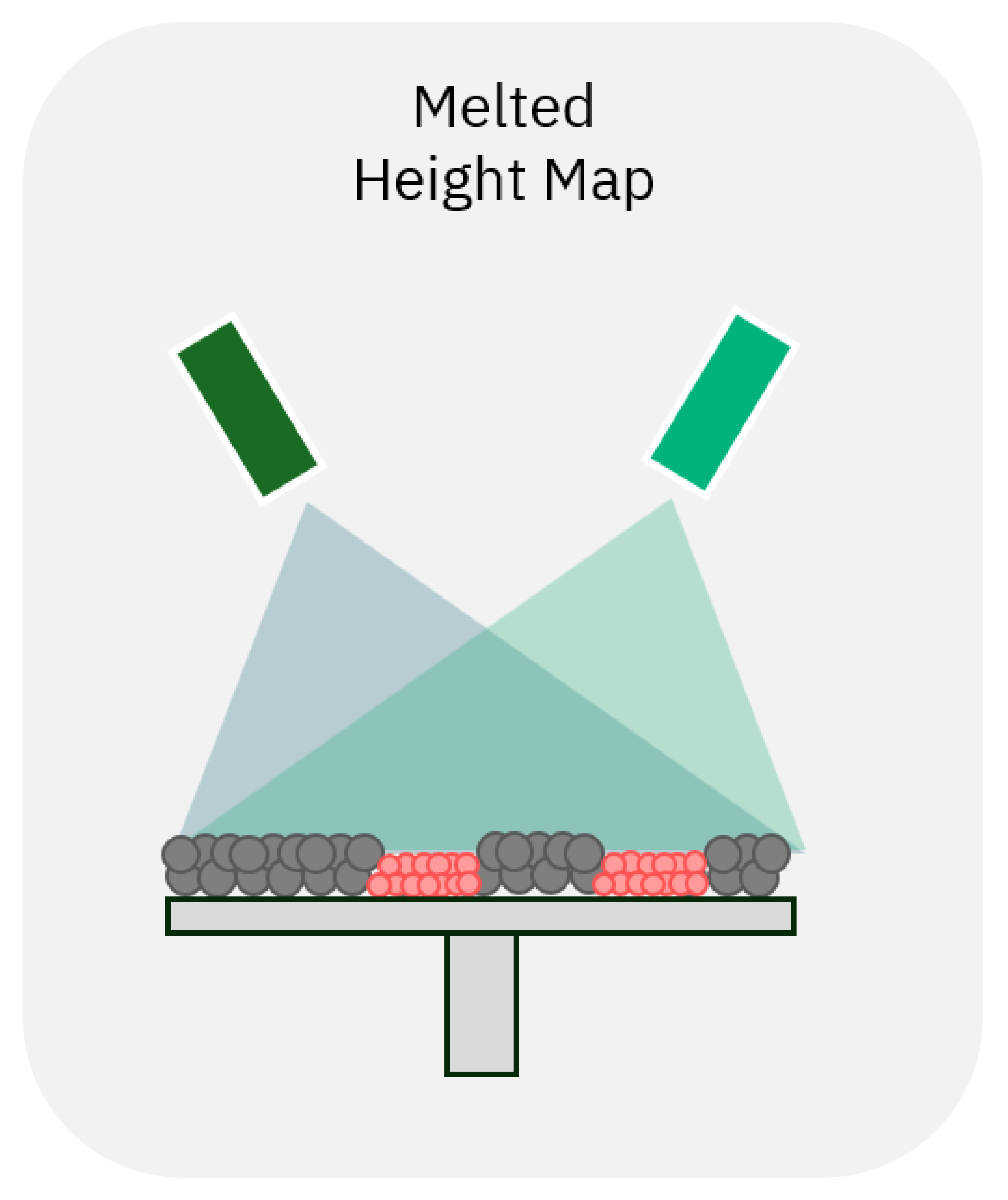

The output from Fringe Inspection is a high-resolution measurement of the build surface or calculated differential of measurements called heightmaps. Every heightmap is a unit-based measurement in X, Y, and Z that is repeatable, calibratable, and has known uncertainty.

The video below demonstrates how fringe projection works in action. In the first scan, a flat reference surface is measured - representing a perfectly flat powder spreading. Here, the projected fringe patterns are uniform spacially across the surface.

The second scan is of a rough surface. The variations in the surface cause distortion in the projected fringe pattern, which is captured by the camera and directly corresponds to differences in height across the area.

Every scan generates a high-resolution heightmap of the AM process, capturing 8,000,000 to 21,000,000+ data points for every measurement. The mathematical constraint algorithms within Fringe Inspection process the heightmaps to acurrately detect and classify anomalies based on their location, severity, and type.

3 Measurements for Every Layer

Scale For Any Machine

The benefit of Fringe Inspection is that the output heightmap is independent of machine size, lighting conditions, or other sensors. Regardless of which machine manufacturer you use, fringe projection outputs the same high-quality measurement for any printer.

Fringe Inspection provides an accurate 1:1 comparison of machine performance and build quality regardless of the build platform size.