Spatter Detection: How Fringe Inspection Links Surface Measurements to Porosity in Metal AM

Discover how Phase3D’s Fringe Inspection™ technology revolutionises spatter detection in metal additive manufacturing (AM) by linking surface roughness measurements to porosity. Unlike traditional camera-based or AI-driven monitoring, Fringe Inspection delivers quantitative, traceable, micron-accurate data, revealing how gas flow inefficiencies and energy density affect part quality.

Streamlining Additive Manufacturing Quality Review with Objective, Measurable Thresholds

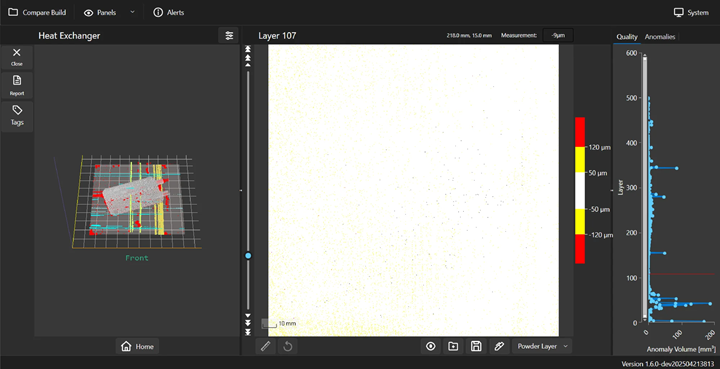

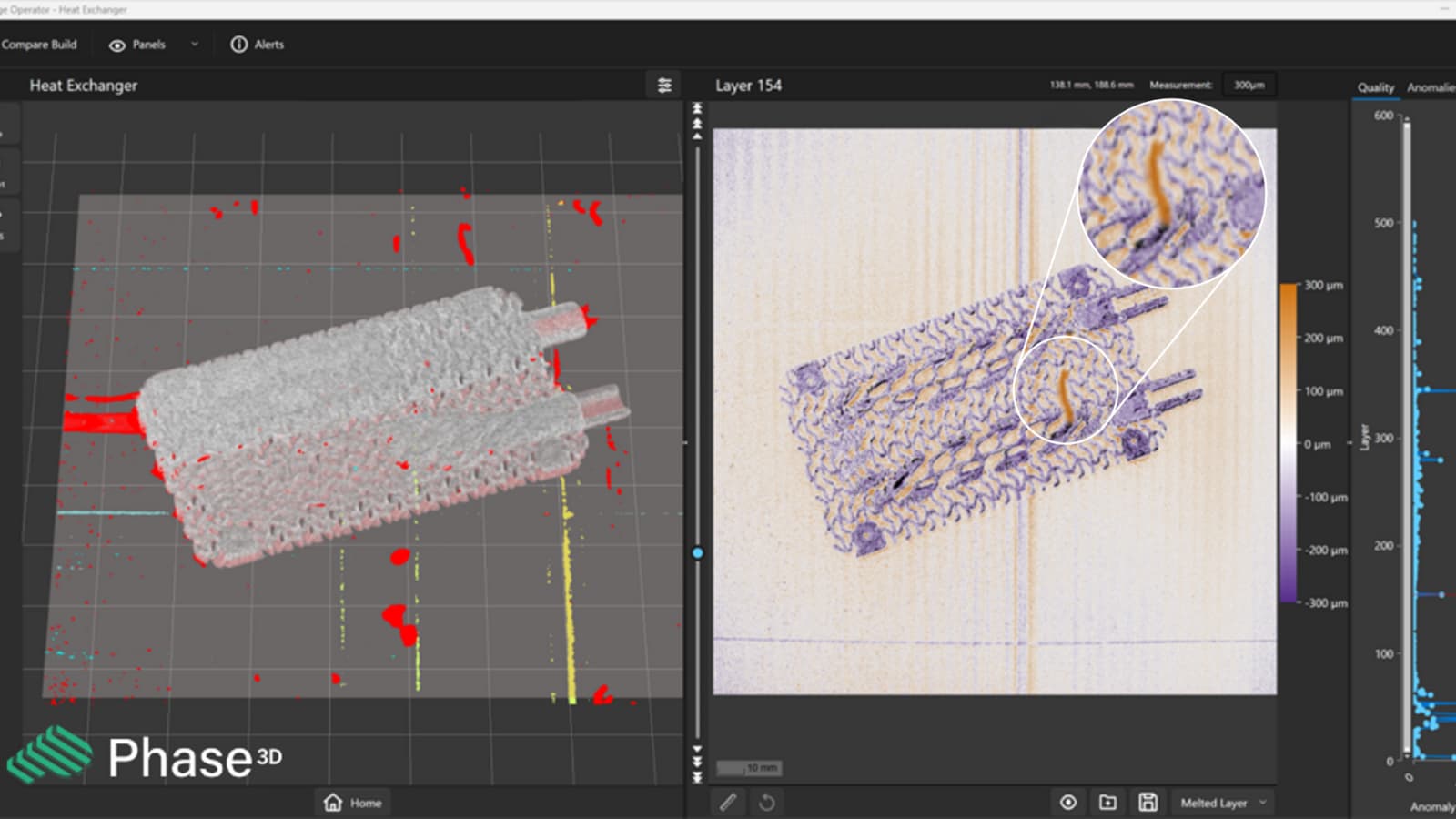

Accelerating Additive Manufacturing Quality Reviews with Fringe Operator™

In high-volume additive manufacturing, inspecting thousands of build layers for anomalies is a major bottleneck. One manufacturer using Phase3D’s Fringe Inspection cut review times by over 70% by combining Quality Chart anomaly visualisation with Adjustable Colorbars.

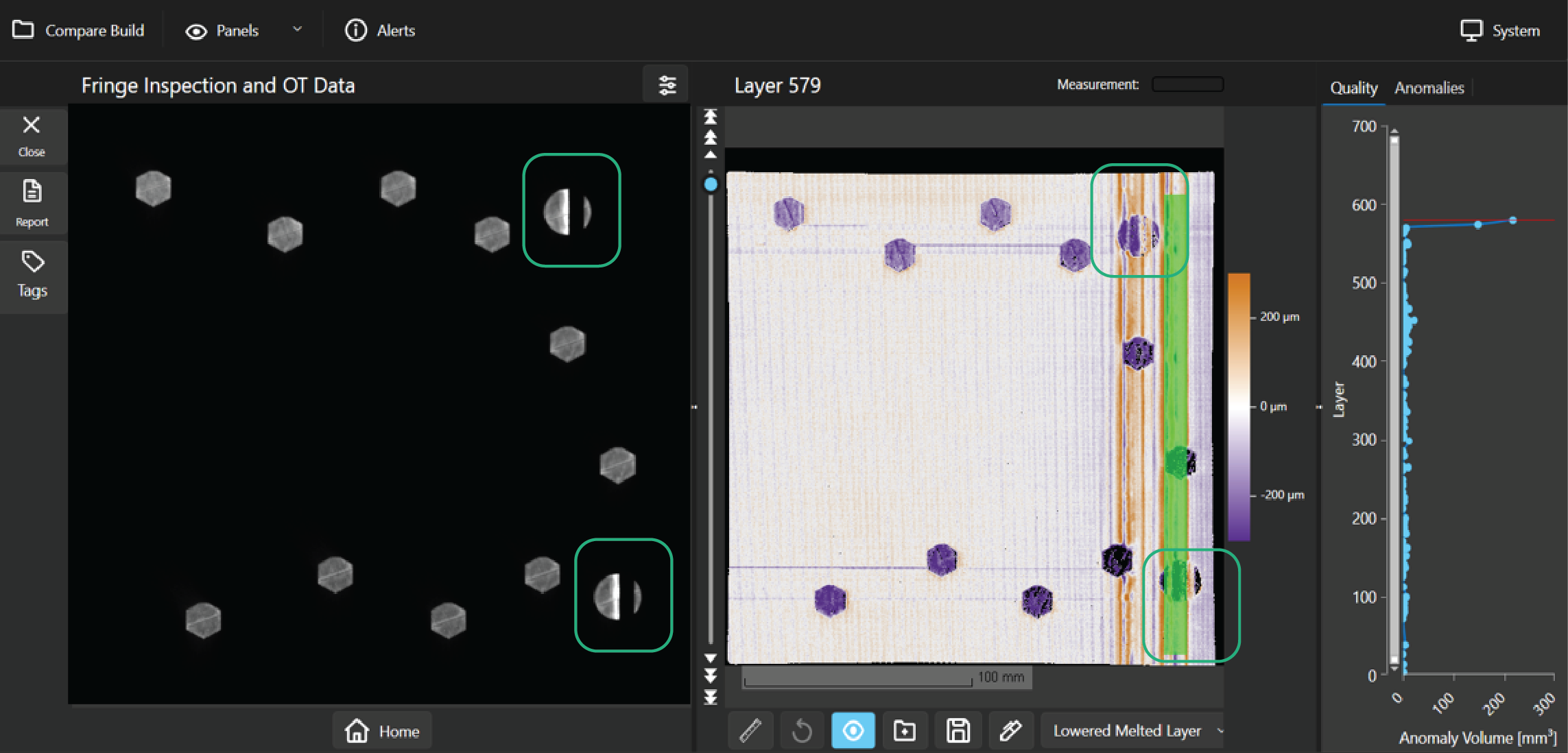

Combining Thermal and Geometric Monitoring to Improve Aerospace AM Quality

Correlating Build Anomalies to Defects in Aerospace Additive Manufacturing with Fringe Inspection™

Ensuring Build Consistency in Serial AM Production with Fringe Inspection™

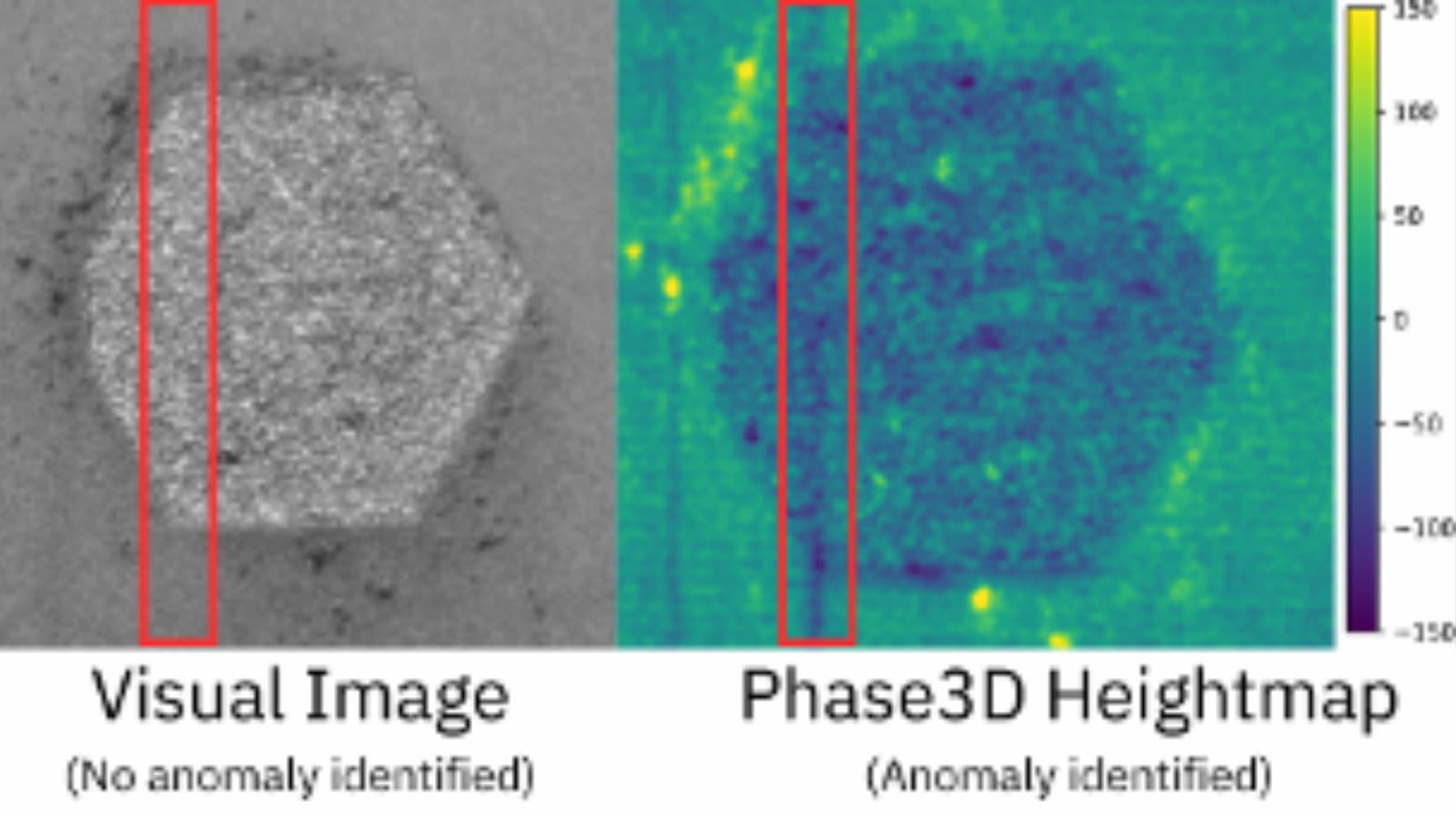

Eliminating the Risks of Visual Image Analysis in Additive Manufacturing with Fringe Inspection™

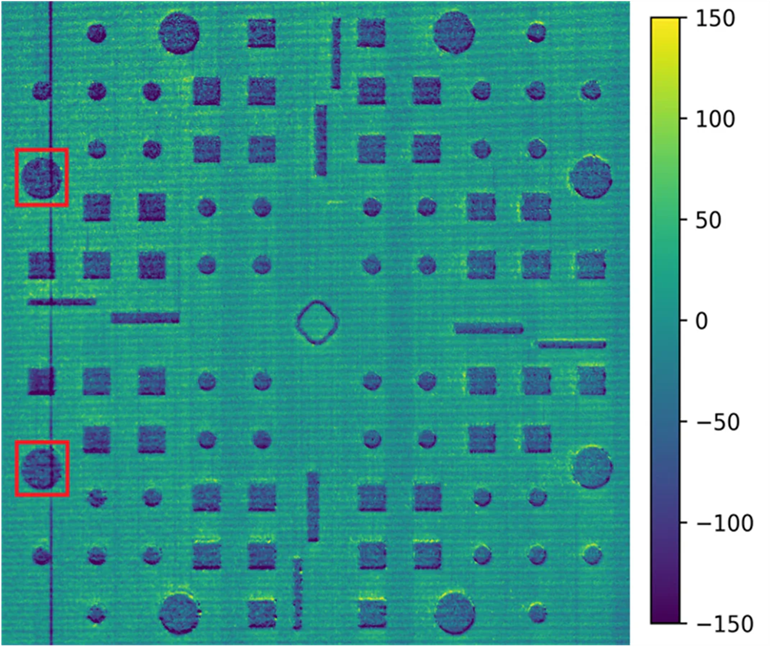

Examining Recoater Damage: How Alloyed is Addressing the Challenge

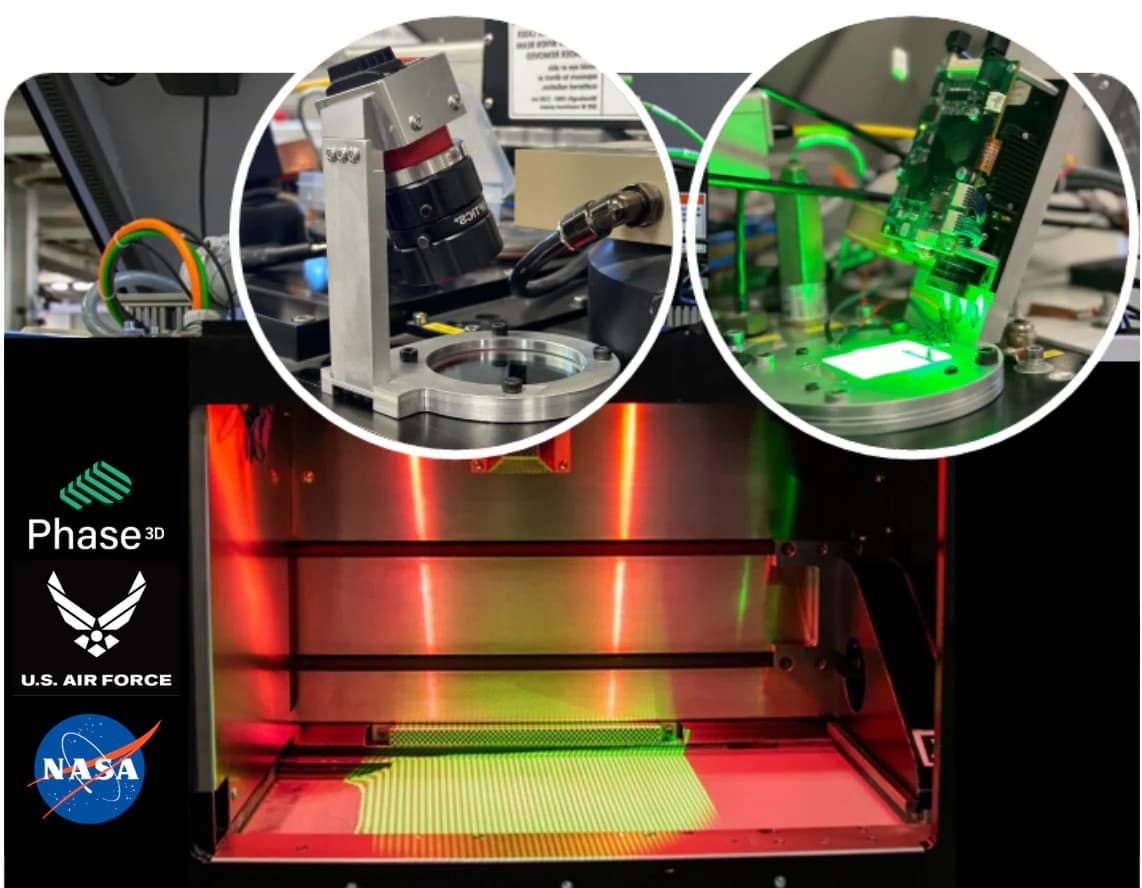

Advancing Binder Jetting Additive Manufacturing with Fringe Research Technology

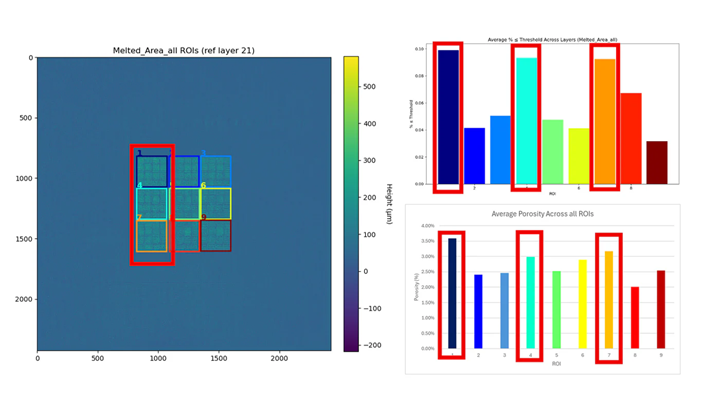

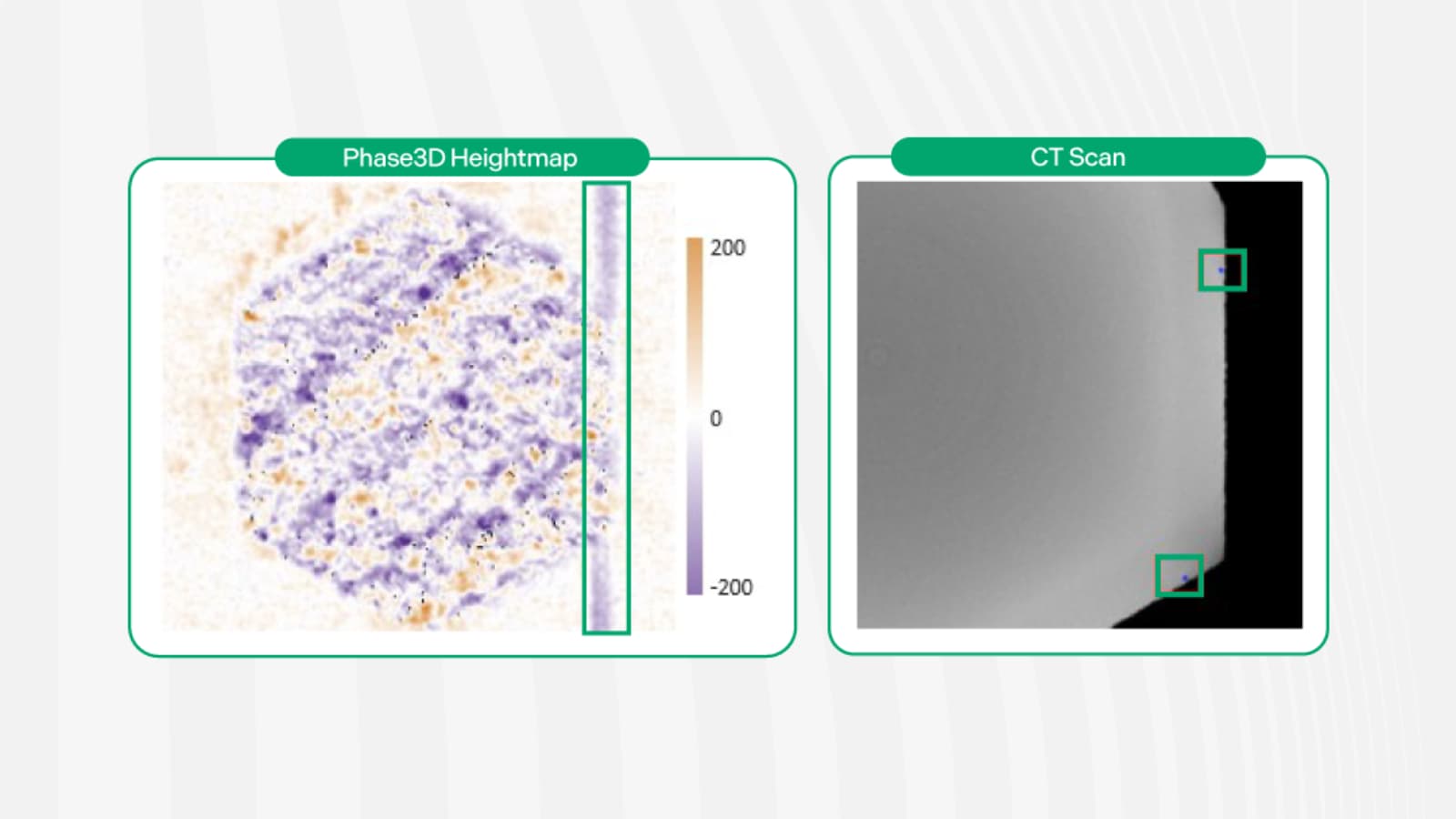

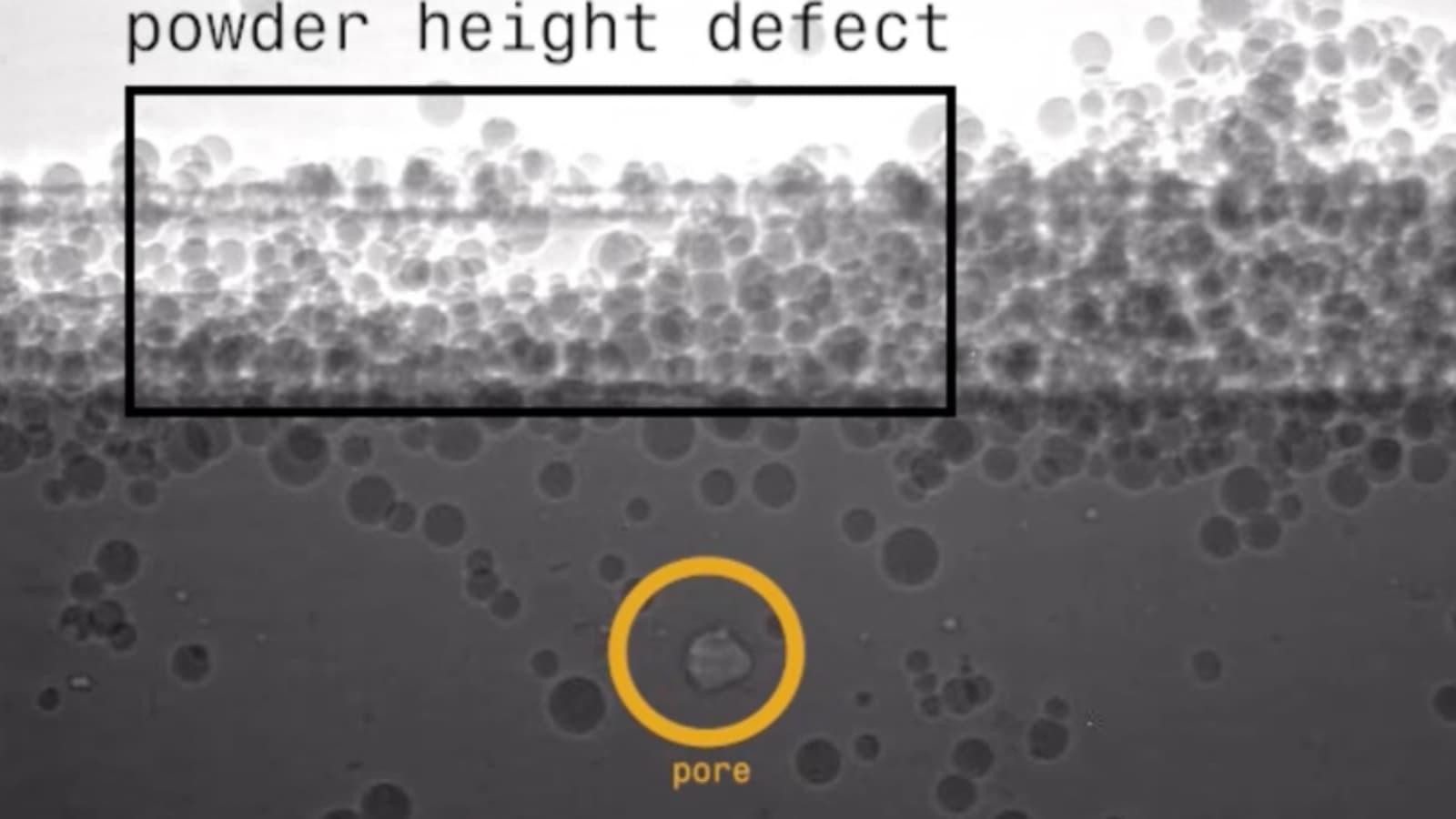

Linking Height Irregularities to Gas Porosity via Synchrotron X-rays