The Challenge: Quick Identification of Critical Anomalies

In production-scale additive manufacturing, quality teams often face a familiar bottleneck – reviewing thousands of layers of build data to identify process anomalies that could compromise part integrity.

One manufacturer using Phase3D’s Fringe Inspection had already seen significant gains in powder bed monitoring. By capturing metrology-grade heightmaps of every layer, their team could detect issues like short feeds, recoater streaks, and powder bed deviations. But even with this powerful data, the task of reviewing full builds remained time-consuming. They wanted a faster, more scalable way to determine which layers warranted deeper inspection, and which could be quickly cleared.

Their goal: enable engineers to immediately flag areas of concern, reduce unnecessary inspection time, and establish objective, repeatable standards for part approval.

The Solution: App-Native Prioritization with Colorbars & Quality Chart

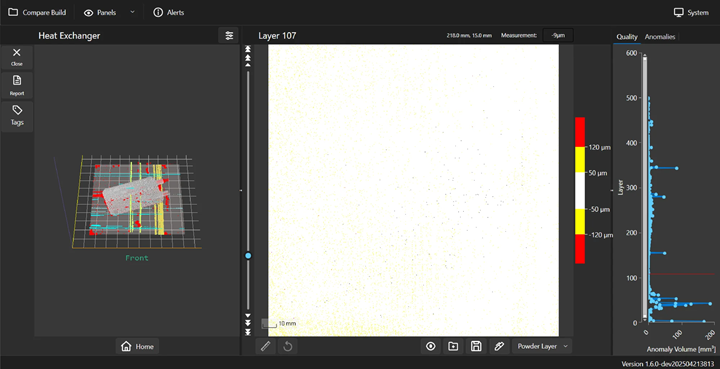

To streamline the review process, the customer began leveraging a combination of two key features within Fringe Operator™, the Quality Chart and Adjustable Colorbars.

Navigating by Anomaly Volume

Using the Quality Chart, the customer could now visualize anomaly volume per layer for the entire build at a glance. Instead of manually scanning every layer, the team jumped straight to problem layers, defined by spikes in surface deviation. This eliminated the need to scroll through each frame sequentially and drastically cut down the time needed for initial triage.

Creating Custom Thresholds

The Adjustable Colorbars feature enabled the customer to define their own heightmap thresholds and assign color-coded categories to different severities of deviation.

- Yellow zones represented anomalies that merited further review – such as mild surface elevation changes, potential short feeds, or minor recoater interactions.

- Red zones indicated severe deviations, often tied to swelling, significant powder redistribution, or irregular melting patterns.

These customizable cues allowed the customer to build an internal review standard based on actual measurement data, tailored to their part geometries, materials, and tolerance requirements.

By overlaying these colorbars on the heightmaps, engineers could immediately spot which parts of the build needed closer inspection, and which could be approved with confidence.

Results: Over 70% Reduction in Review Time

The impact of this dual-feature workflow was immediate and measurable:

- Build review time dropped by more than 70%, allowing the quality team to move from reactive inspection to proactive process monitoring.

- Engineers focused their attention only on critical anomalies, reducing redundant analysis and inspection overhead.

- Measurement-based, objective review standards replaced subjective assessments, improving consistency across operators and builds.

Rather than sorting through every layer manually, the team could now rely on both quantitative and objective indicators to guide their decision-making.

What’s Next: Scaling & Refining Quality Criteria

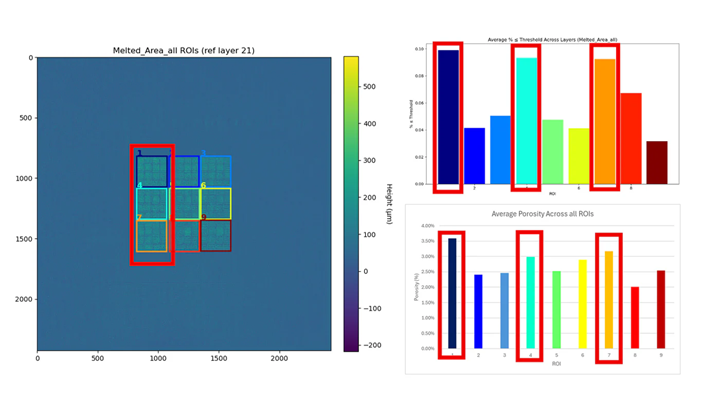

Building on this success, the customer plans to further refine and scale their Fringe Inspection workflows:

-

Correlating in-situ anomalies with CT data will allow the team to sharpen the precision of their yellow and red thresholds, ensuring that only defect-critical deviations are escalated.

- Creating a library of colorbar presets for different part types, machines, and materials will support a more modular and efficient review process across projects and teams.

By combining real-time heightmap data with objective, defect volume insights, this manufacturer has transformed their AM quality review process, laying the foundation for faster, smarter, and more scalable in-situ inspection.

Share: