Phase3D Releases Two Large-Format Fringe Inspection Systems for Metal Additive Manufacturing

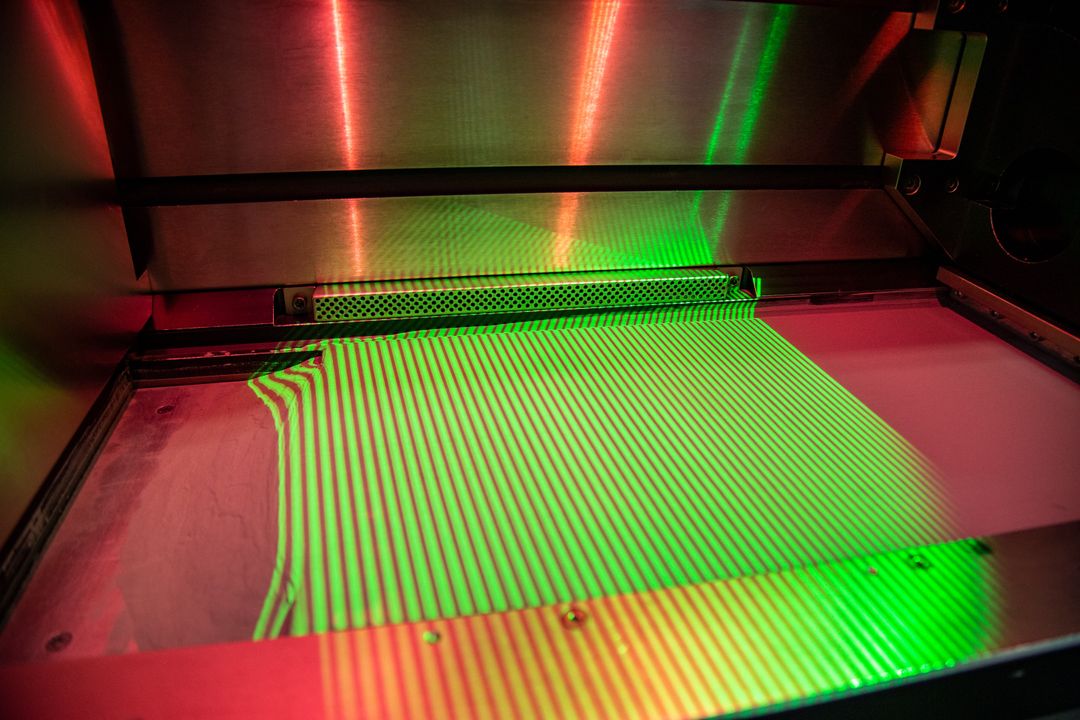

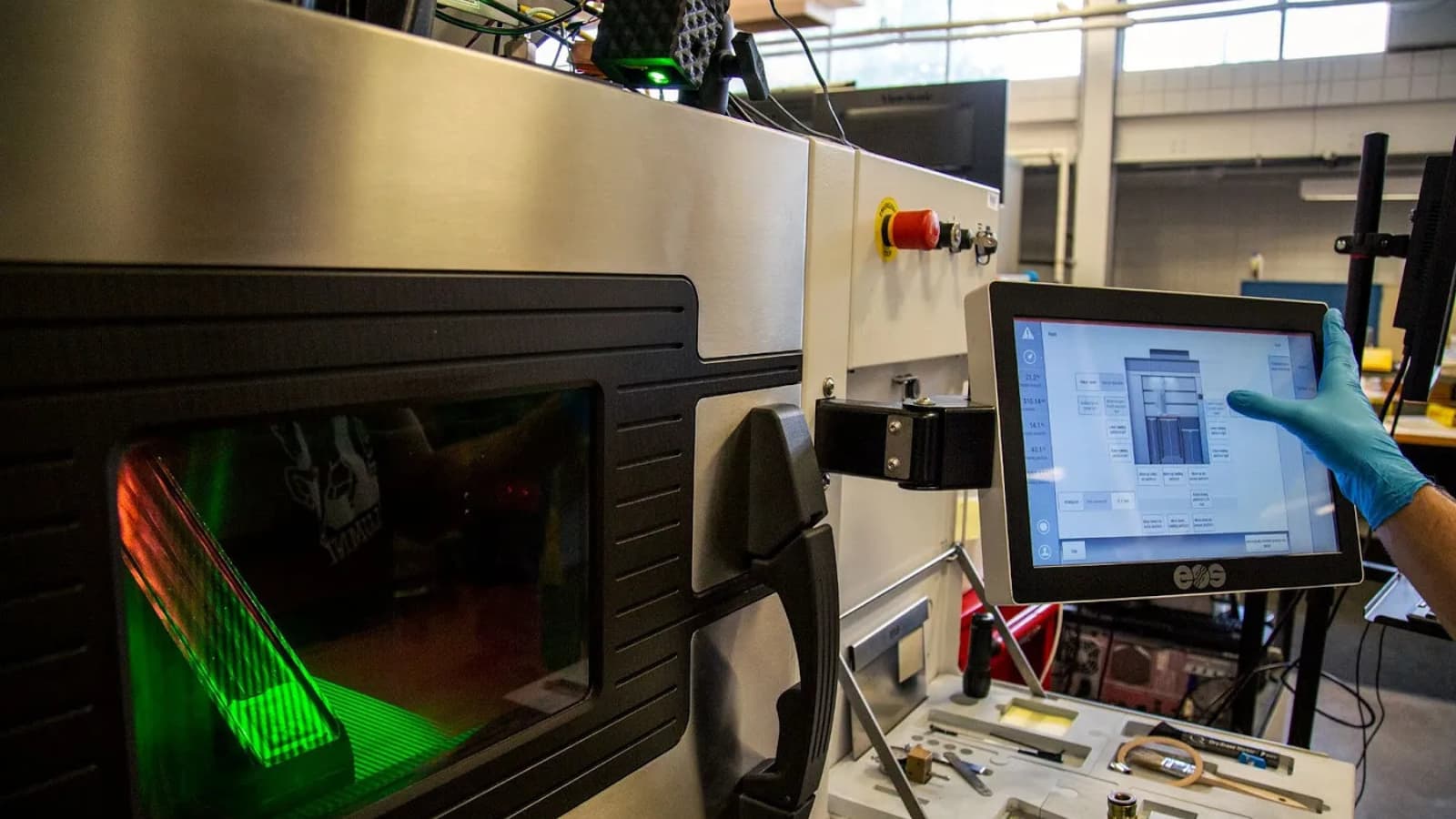

Phase3D today announced the release of two new large-format Fringe Inspection™ Systems for metal additive manufacturing. The new systems, Large Format Fringe Inspection™ and Large Format Fringe Inspection™ Hi-Rez, extend Phase3D’s in-situ inspection technology to support the EOS M 400 series of printers and other large-format platforms such as the Nikon SLM NXG product line.

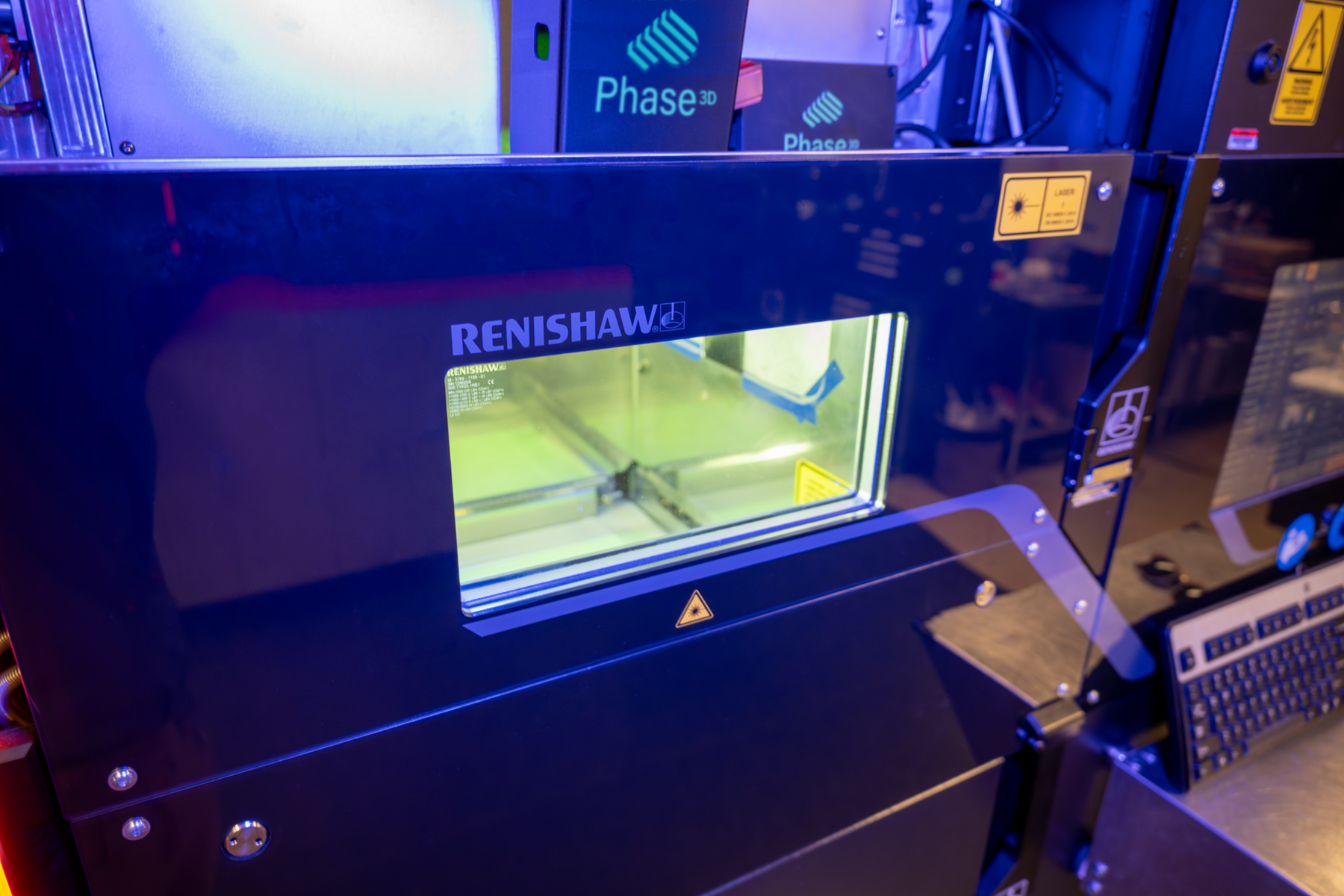

Fringe Inspection™ Now Available for Renishaw 500Q

Phase3D Named Finalist in ASTRO America’s In- Situ Awareness Challenge

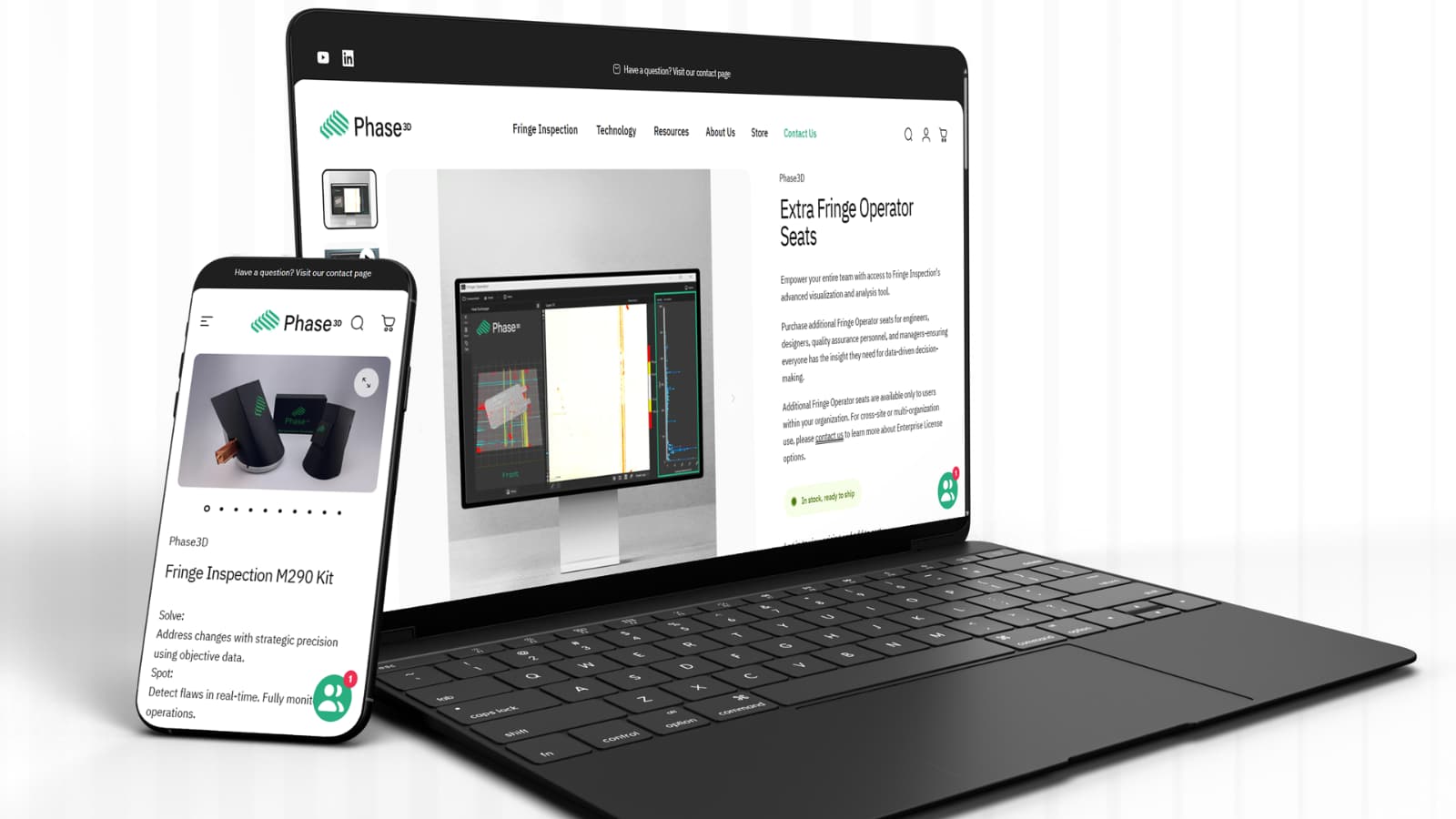

Phase3D Launches Online Store to Streamline Access to Fringe Inspection™ for Additive Manufacturing

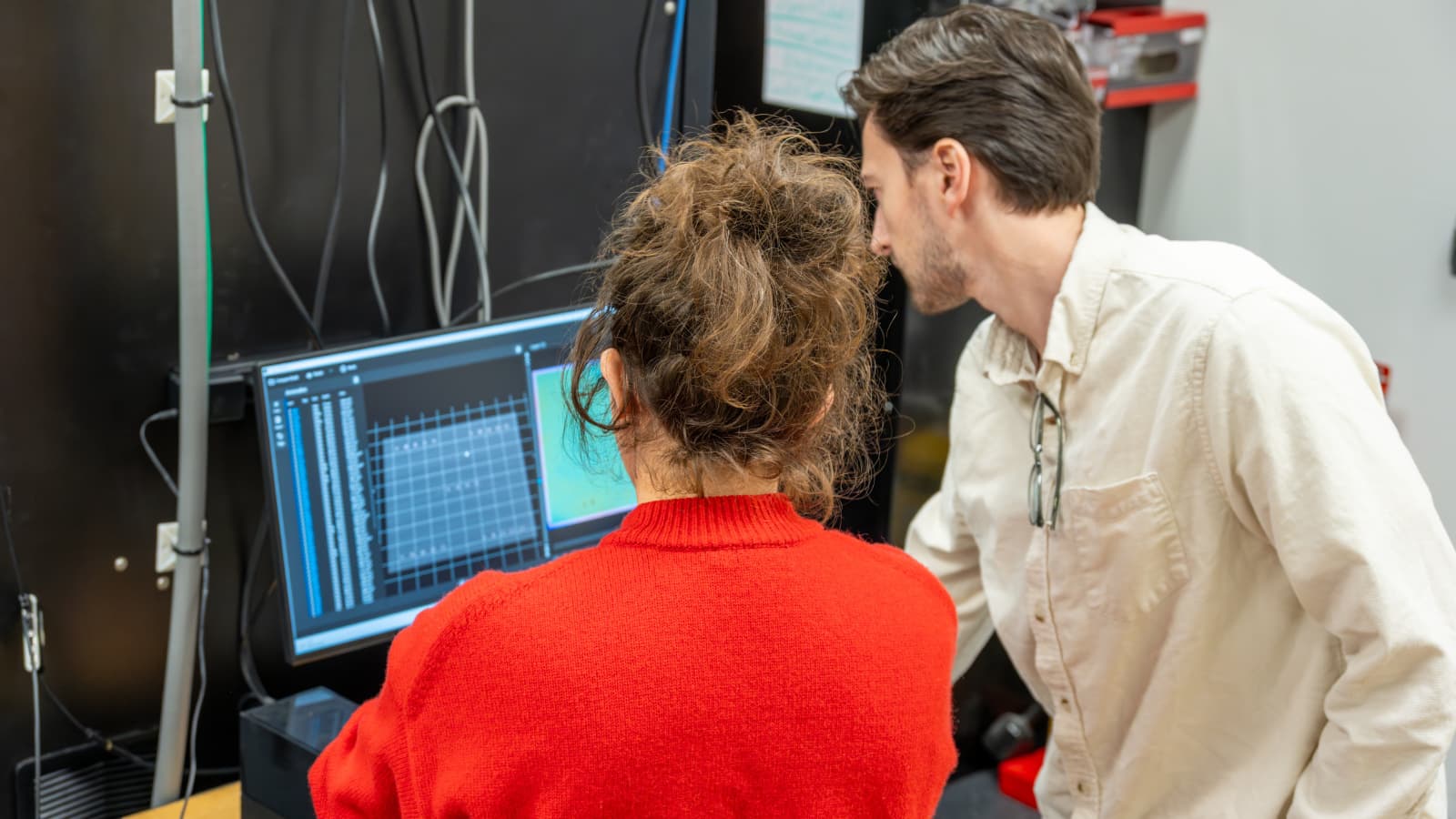

Fringe Inspection™ Installed at HRL Laboratories for Groundbreaking SPARES Project

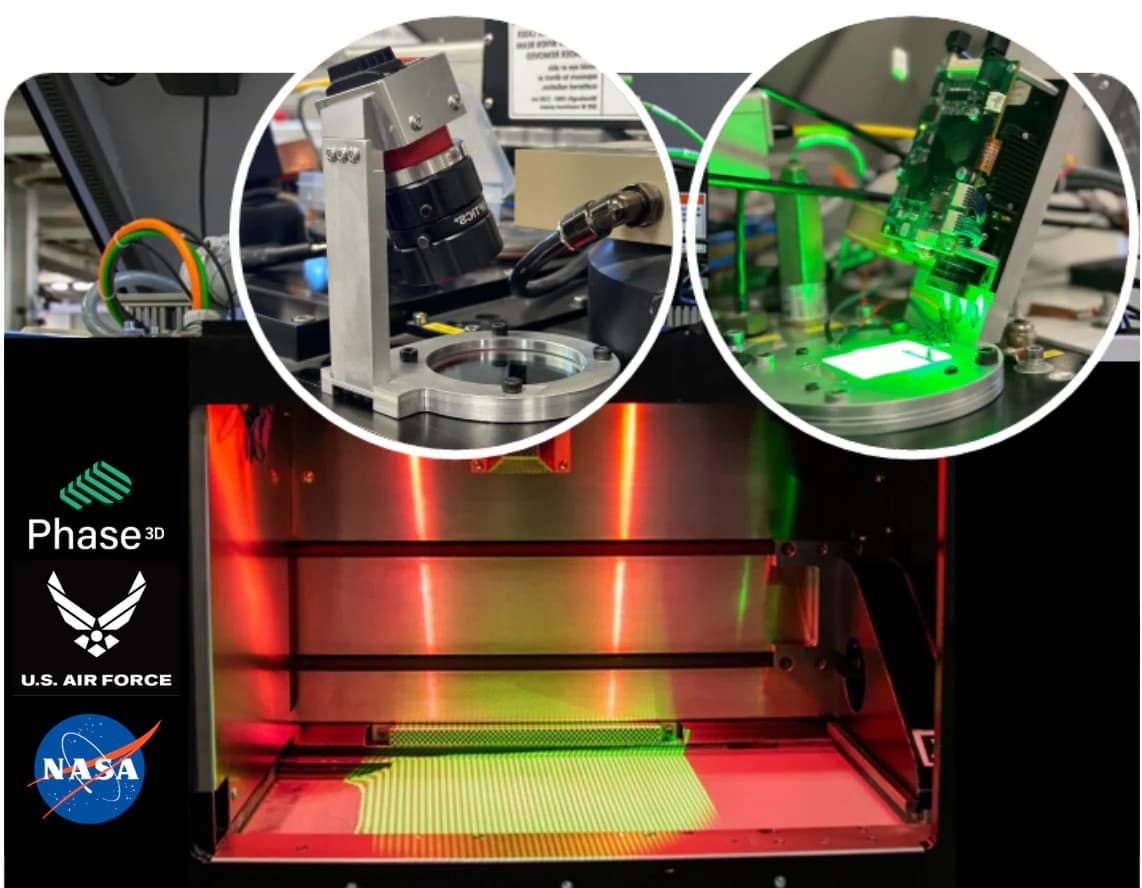

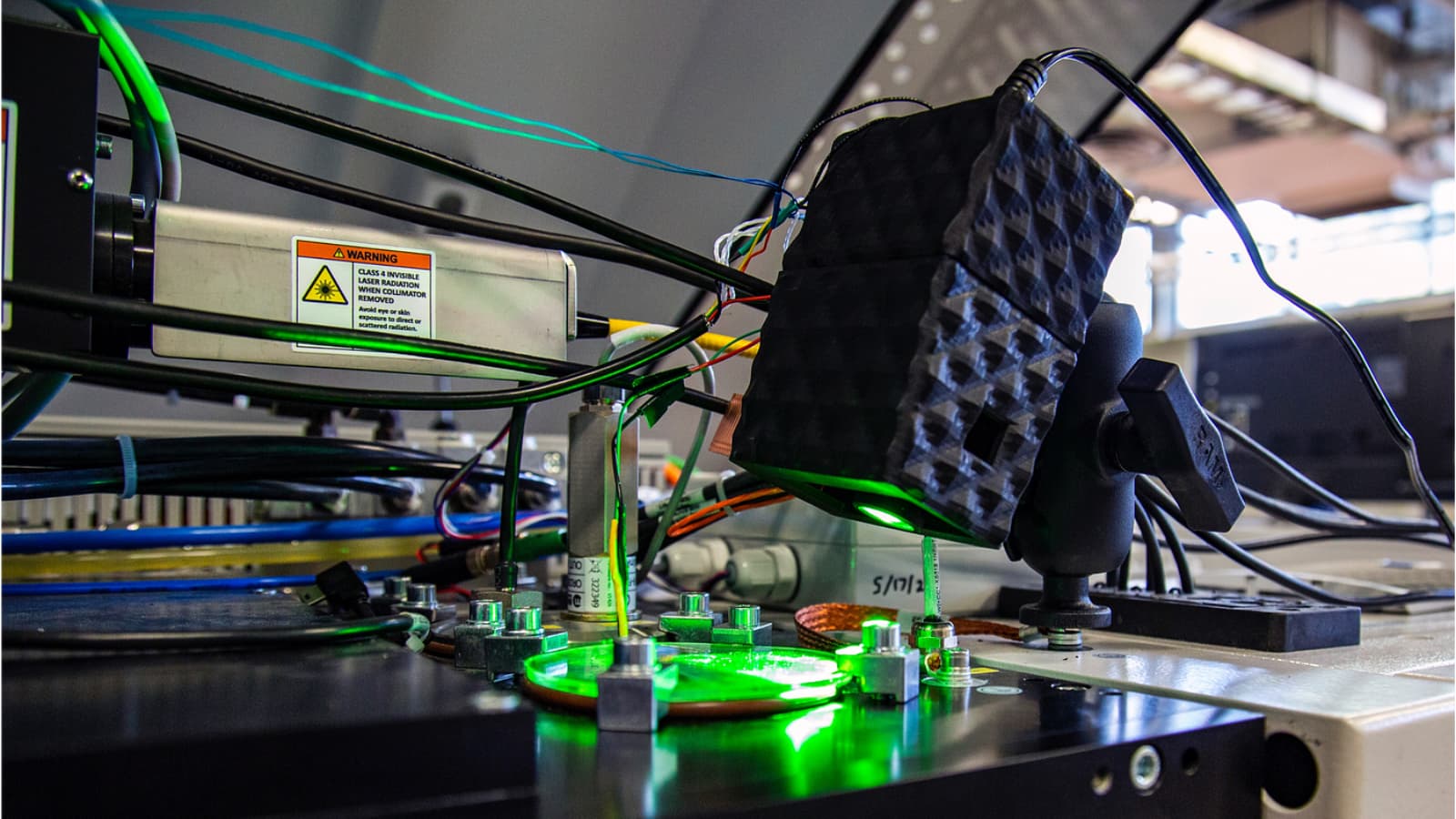

Phase3D Successfully Completes $1.25M Air Force Cold Spray Quality Inspection Product Deployment

Spotlight on Innovation: Dr. Niall O’Dowd Named Finalist for 2025 Chancellor’s Innovation Award

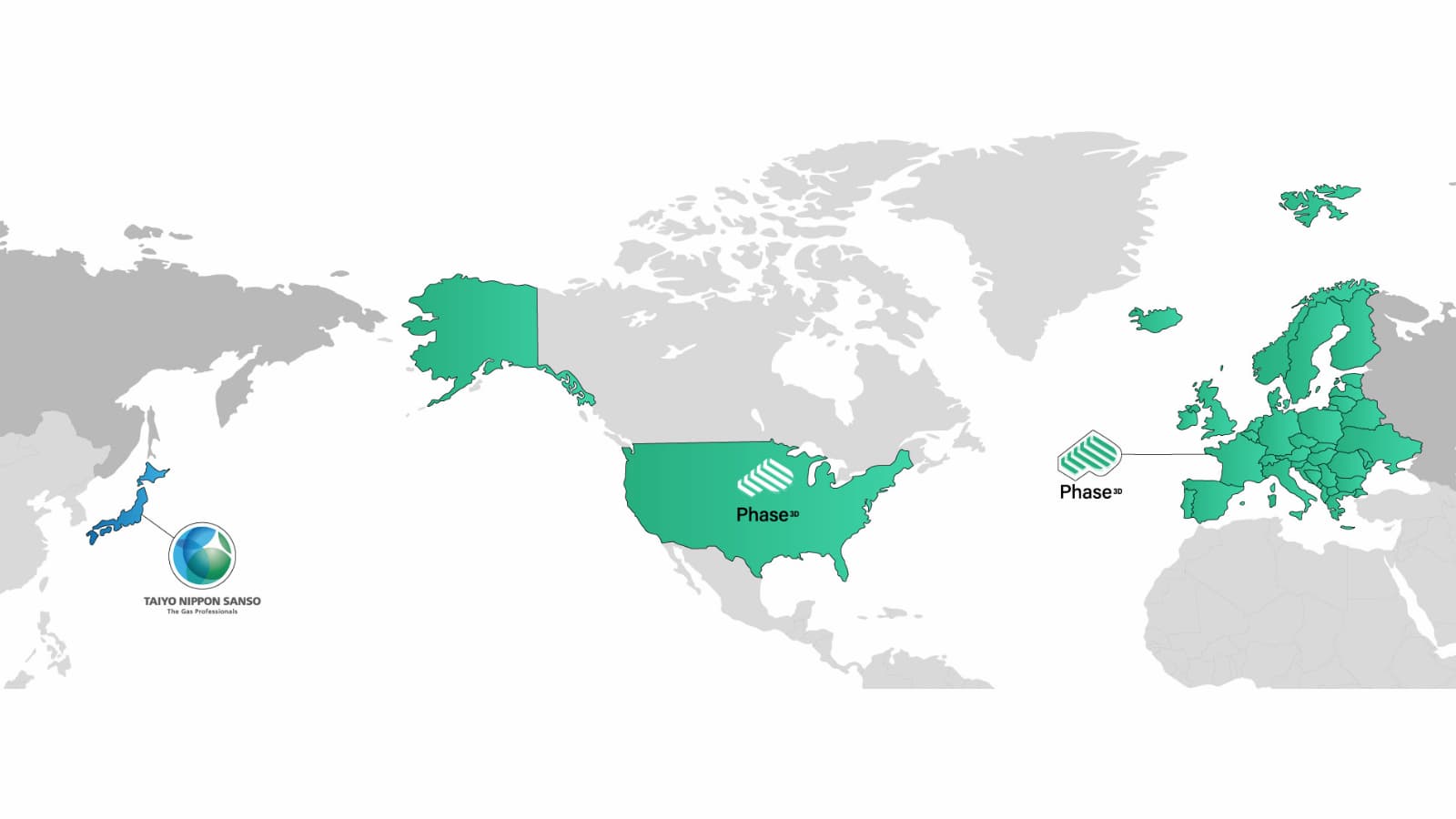

Phase3D Expands into Japanese Market Through Strategic Partnership with TNSC

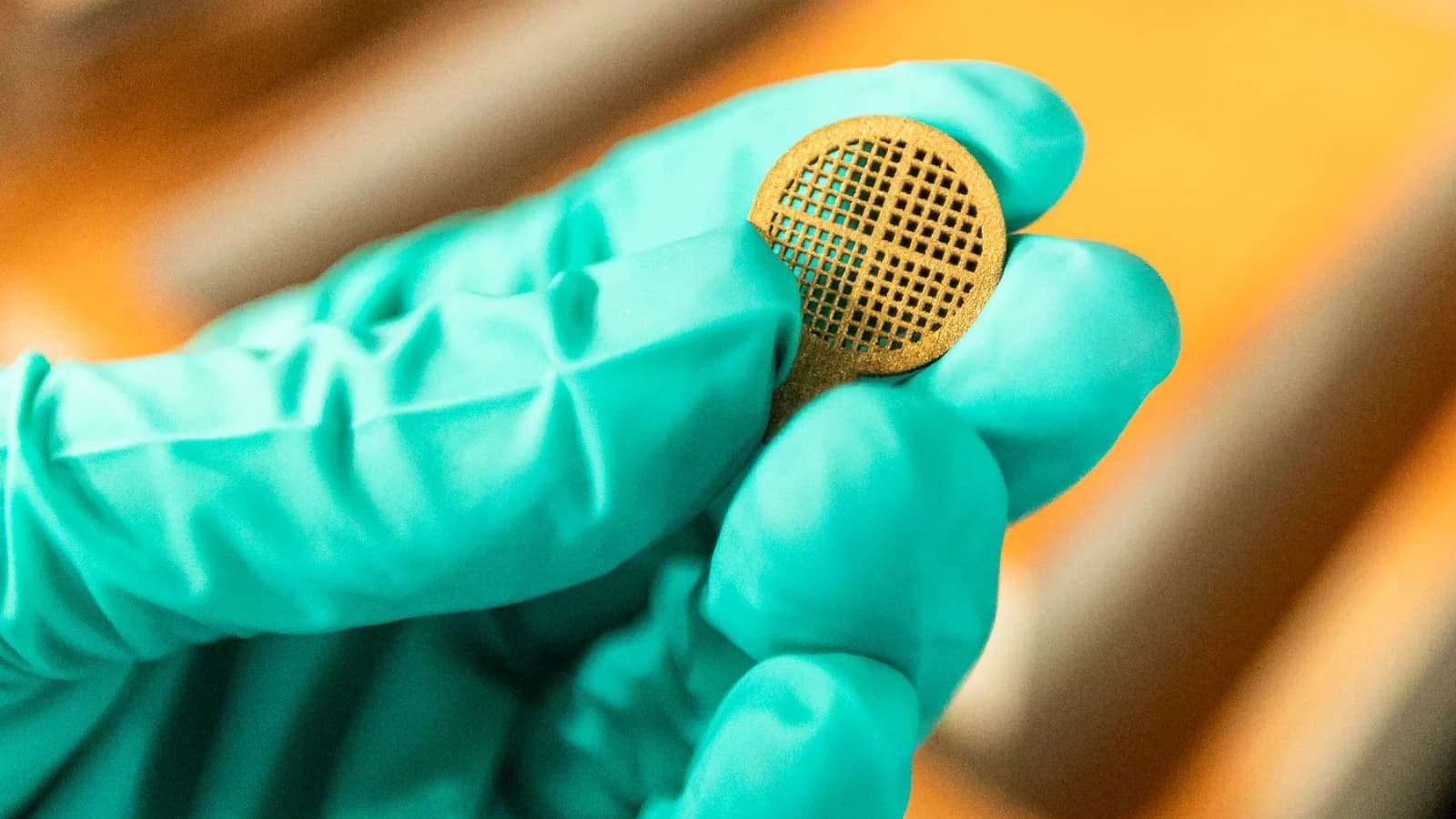

The Future of Aviation with Additive Manufacturing Requires In-Situ Inspection

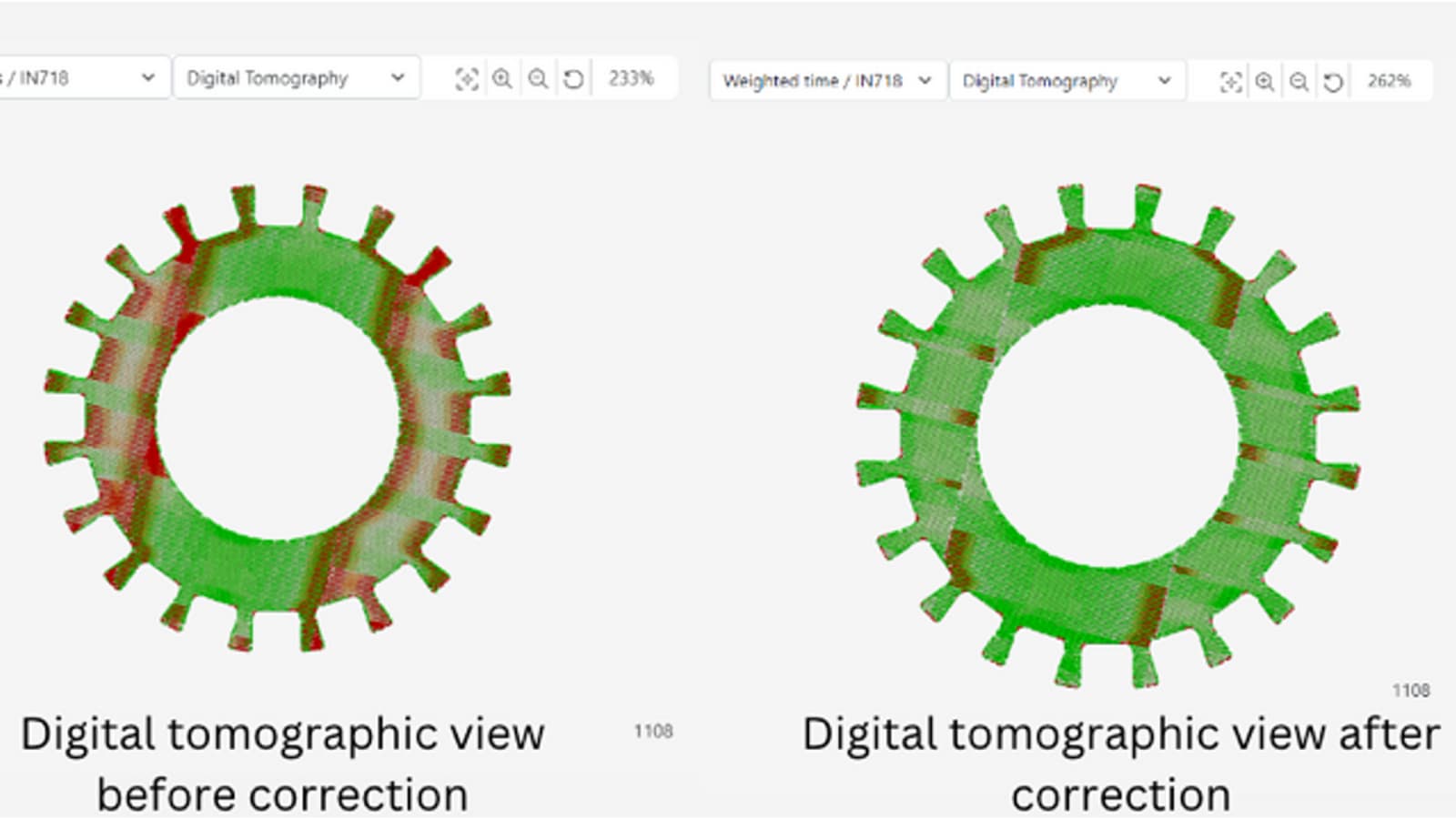

Advancing AM Quality and Reliability

Phase3D Develops Real-Time Inspection for Air Force Additive Manufacturing

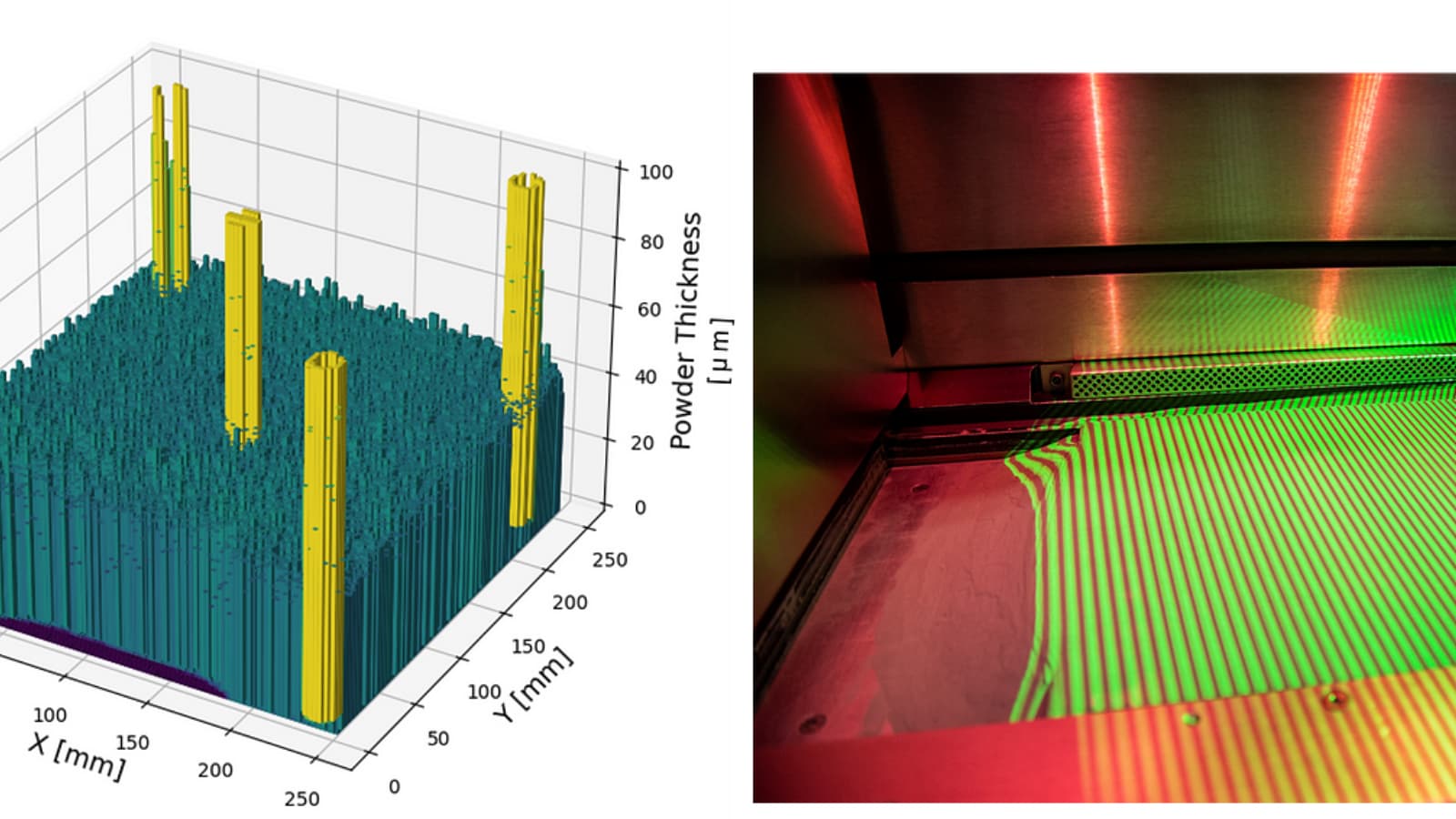

Phase3D Introduces Advanced Layer Thickness Measurement

Behind the Build: Niall O’Dowd Talks AM Innovation on the 3Degrees Podcast

Phase3D Secures $1.25M US Air Force Contract for Cold Spray Additive

Phase3D and DMG MORI Launch Research Collaboration

Phase3D and 1000Kelvin Win US Air Force STTR Contract

Phase3D Partners with Materialise

Phase3D Launches Early Adopter Program for 3D Printing Inspection

Phase3D Completes Collaboration with Oak Ridge National Lab

Phase3D Wins Air Force Innovation Open Call

Additive Monitoring Systems is now Phase3D