We’re thrilled to share that Phase3D has joined HRL Laboratories and a coalition of leading institutions on SPARES – a DARPA-funded initiative aimed at advancing structural reliability in metal additive manufacturing.

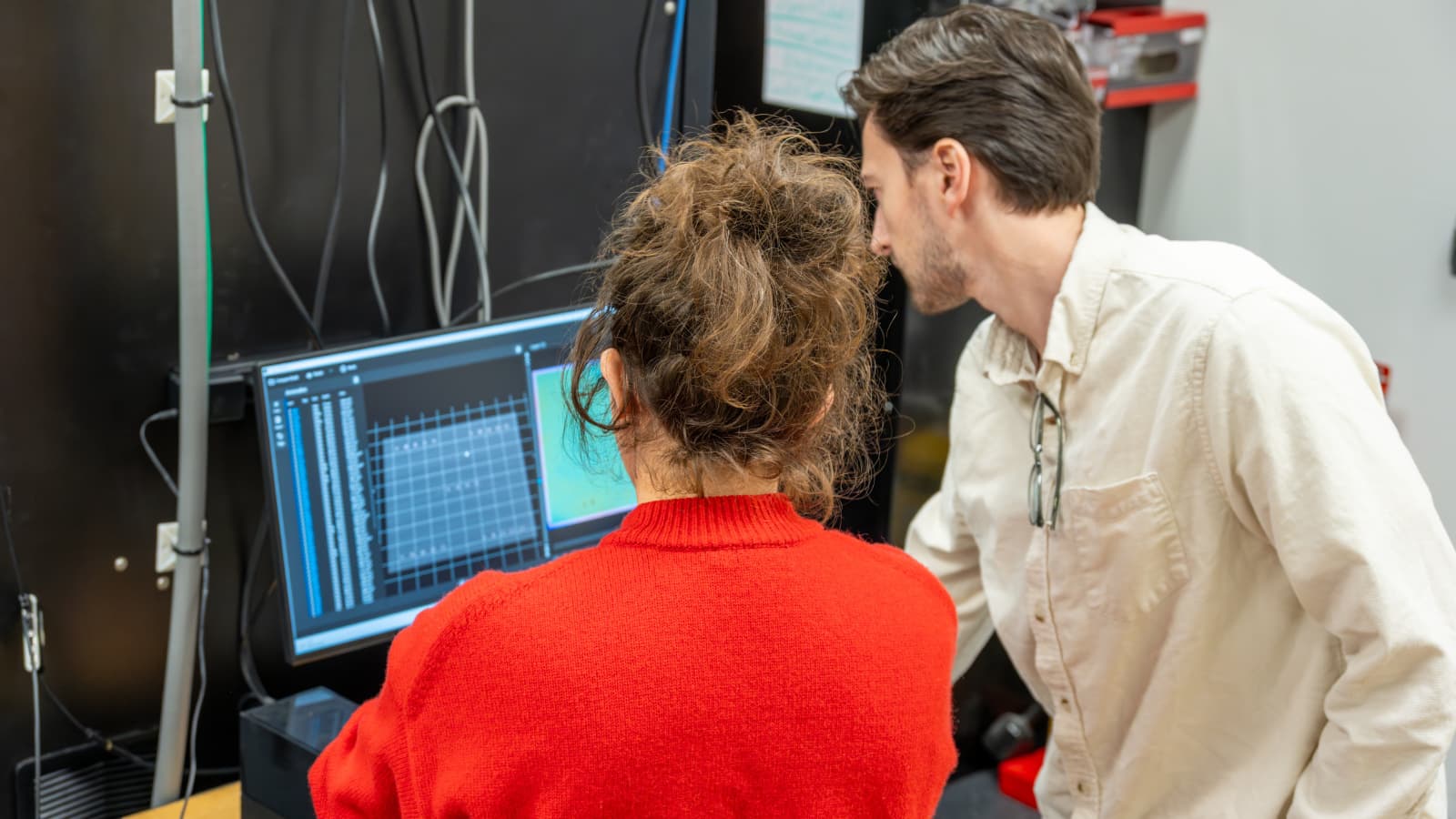

Our team recently visited HRL’s Malibu, California facility to install Fringe Inspection™, our real-time, layer-by-layer surface inspection product. This deployment marks a key milestone in the SPARES program (Surrogate‐accelerated, Physics‐guided Assessment for the Reliability of Structures), which seeks to transform how engineers qualify metal parts, without relying solely on destructive testing.

What Is SPARES?

Led by HRL Laboratories, and supported by partners including Boeing, Purdue University, and the University of Utah, SPARES is part of DARPA’s SURGE program (Structures Uniquely Resolved to Guarantee Endurance). The goal: accelerate and improve the structural reliability of AM parts by fusing:

- Physics-based simulation

- AI-driven surrogate modeling

- In-situ process monitoring

By integrating real-time build data with predictive modeling, SPARES offers a smarter, faster way to assess part performance – reducing the need for costly, time-consuming testing after the build.

How Fringe Inspection™ Fits In

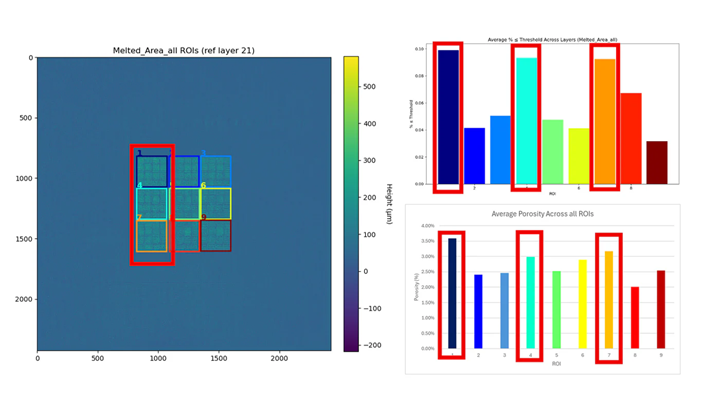

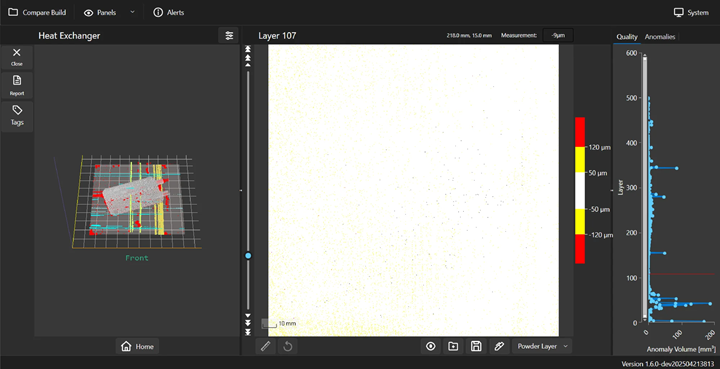

Fringe Inspection™ plays a critical role in SPARES by supplying the objective, layer-resolved data that drives predictive qualification.

Our structured light system captures topology height maps during every layer of the build, allowing users to detect defects early, inspect process stability, and create a traceable digital record of the entire print. Within the SPARES framework, this data:

- Powers surrogate models that predict fatigue and structural performance

- Identifies subtle variations that could compromise part life

- Supports non-destructive qualification for high-reliability applications

This represents a fundamental shift away from post-process analysis. With Fringe Inspection™, engineers can evaluate part integrity before it ever leaves the machine.

Installed on the Renishaw 500Q – With More to Come

We’re especially excited to note that this Fringe Inspection installation was completed on a Renishaw 500Q system. This capability will be available as part of our Fringe Inspection 500 Kit, and a full product launch is scheduled for late July.

Stay tuned, we’ll be sharing more details soon about how manufacturers across industries can equip their Renishaw machines with real-time, in-situ quality assurance.

A Step Toward Smarter, Safer Manufacturing

The implications of SPARES go far beyond the lab. From aerospace to defense to automotive, manufacturers are under pressure to scale metal AM while meeting strict reliability and safety standards. By uniting real-time data with intelligent modeling, SPARES is proving that it’s possible to move from reactive inspection to predictive qualification, without compromise.

We’re honored that Fringe Inspection™ is a foundational part of this groundbreaking effort and proud to support HRL Laboratories and the entire SPARES team as we push the boundaries of what’s possible in additive manufacturing.

Want to learn how Fringe Inspection™ can improve your AM process? Contact us.

Share: