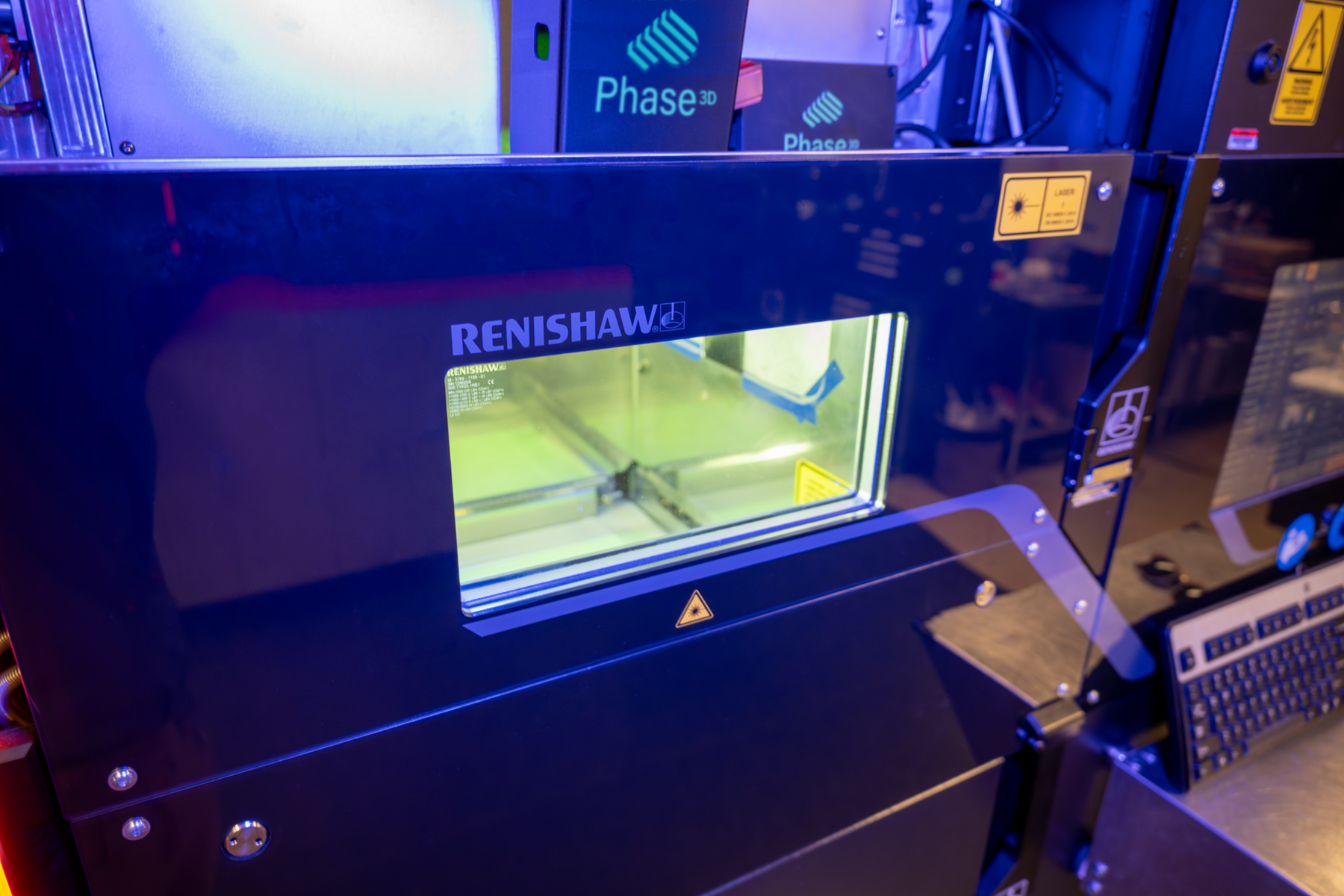

Phase3D’s breakthrough in-situ quality assurance solution, Fringe Inspection, is now available for the Renishaw 500Q and other 500-series platforms (500S, 500D, and 500Flex). The new Fringe Inspection 500 Kit delivers high-resolution, layer-by-layer heightmaps for powder bed fusion users seeking to advance their metal additive manufacturing using the only repeatable, calibratable, unit based in-situ inspection product on the market. Fringe Inspection is optimized for qualification to production, including the material and product development process, to reduce scrap, optimize production workstreams, and enable metal additive manufacturing to be used for critical-use applications at economic scales.

“We’re thrilled to expand our offering to the Renishaw 500Q. With this launch, our current customers can now access the latest and greatest in in-situ inspection on their 500Q platforms as well as expanding into new production facilities. Fringe Inspection is purpose-built to meet the demands of today’s most advanced metal additive manufacturing systems and many of those users have 500Qs on their production floor,” said Niall O’Dowd, PhD, Founder & CEO of Phase3D.

Developed in collaboration with HRL Laboratories, a renowned research institution known for its leadership in materials science and additive manufacturing innovation, the Fringe Inspection for Renishaw 500q is fully non-invasive, reversible, and can be installed in just 24 hours with minimal machine downtime. This product was developed to directly support the DARPA SURGE initiative, a historic push for the United States to develop quality assured AM part production.

“Collaborating with Phase3D allowed us to unlock new insights into the printing process. Fringe Inspection augments our in-situ sensor suite with high-fidelity, layer-by-layer data, which greatly enhances our ability to assess part quality while printing,” said Eric Clough, R&D Group Lead at HRL Laboratories.

Courtesy of HRL Laboratories

Courtesy of HRL Laboratories

What Is Fringe Inspection?

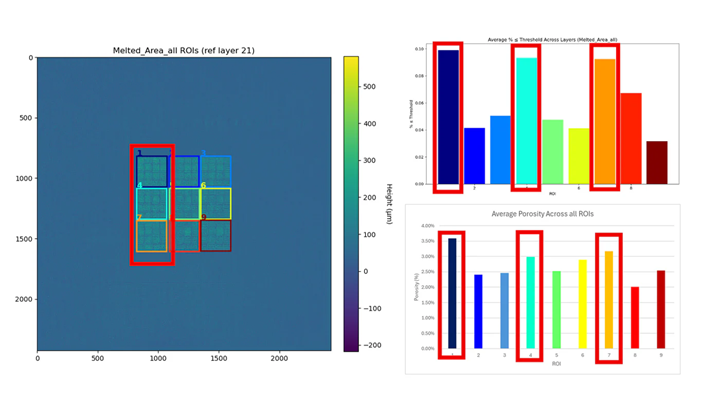

Fringe Inspection is a structured light inspection system that uses digital fringe projection to capture a full-field Z-height maps of every layer in a powder bed fusion build. Unlike visual images, coaxial, or thermal systems that only capture qualitative images, Fringe Inspection provides true metrology measurements at micron scale to quantify anomalies in real time.

Courtesy of HRL Laboratories

Courtesy of HRL Laboratories

Key Capabilities of Fringe Inspection 500Q Kit:

· Layer-by-layer heightmaps, measured with sub-10 µm repeatability

· No added cycle time, with <1 second capture per layer

· Quantifying automatically detected anomalies: recoater streaks, hops, part protrusions, short feeds, powder dropping, spatter, and more

· Easy installation, calibration, and validation in less than 24 hours

Installation on Renishaw 500Q

Courtesy of HRL Laboratories

Courtesy of HRL Laboratories

To bring Fringe Inspection to the Renishaw 500Q and other 500-series platforms, Phase3D engineered a drop-in hardware package optimized for OEM compatibility. Key installation features include:

· Camera Assembly Swap: Renishaw’s stock camera is removed and replaced with the Phase3D projector assembly

· Laser-Safety Camera Port: A custom-designed laser-safe glass fixture replaces the right-side lightport. This fixture preserves gas flow, ensuring no compromise to the thermal or gas flow process.

· Quick Deployment: The full install, including calibration, validation, a short test print, and on-site customer training, is completed in 24 calendar hours (noon to noon) by a Phase3D technician.

· Non-Invasive and Reversible: All changes are easily reverted, allowing users to return the machine to its original configuration if needed.

Fringe Inspection Data

Fringe Inspection on the 500Q outputs three distinct heightmaps for every layer, providing a comprehensive view of the powder bed fusion process:

1. Powder Heightmap: Captured immediately after the powder is spread, this map shows the uniformity or anomalies of the powder across the build plane.

2. Melted Heightmap: Captured after the laser fuses the powder, this map reveals how the melt process has altered the surface profile and detects spatter, melted region variations, and powder redistribution.

3. True Layer Thickness: This is a calculated heightmap that quantifies the actual amount of powder deposited over every layer. It is derived by taking a heightmap after the build elevator repositions and subtracting that from the powder heightmap. This provides direct insight into powder delivery and process stability.

Fringe Inspection also outputs a visual image corresponding to every heightmap, enabling users to maintain traditional image-based layer assessment while benefiting from precise, quantitative data.

Heightmap Output: Data That Drives Decisions

Fringe Inspection on the 500Q generates precision heightmaps for every printed layer, revealing in real time where the build process deviates. Outputs include:

· Repeatability: ±10 µm

· Absolute planar deviation: ±50 µm (σ = 20 µm)

· Full-bed coverage: 250mm field of view

· Optimal capture angle: 36° from normal

· Measurement time per layer: <1 second

Download the Fringe Inspection 500Q Kit Specification

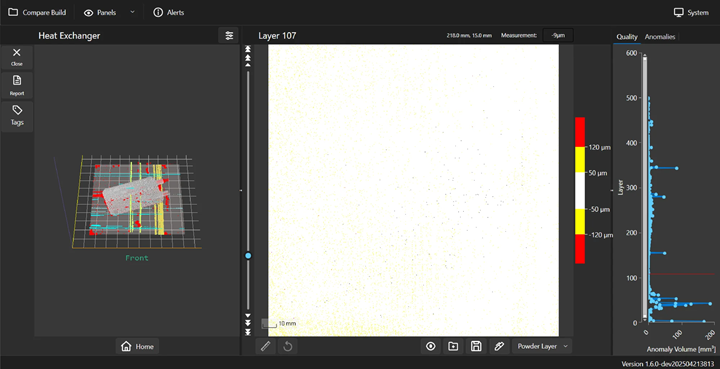

Data Access Through Fringe Operator™ and Fringe Qualification™

Fringe Inspection data from the Renishaw 500Q is made accessible through Phase3D’s software suite, Fringe Operator and Fringe Qualification, providing both real-time and post-build insights.

- Fringe Operator delivers live visualization and analysis of every heightmaps: powder, melted, and true layer thickness to help operators detect build failing anomalies in real time. Learn more about Fringe Operator features here: https://www.phase-3d.com/pages/fringe-operator

-

Fringe Qualification enables real-time dashboard of the production floor, as well as post-build validation, comparison across builds, machine performance tracking, and generation of certification reports to support traceability for critical applications and production workflows. Learn more about Fringe Qualification features here: https://www.phase-3d.com/pages/fringe-qualification-software

For advanced users, Fringe Inspection heightmap data can also be accessed via scripting interfaces upon request, allowing for deeper integration into custom analytics pipelines or manufacturing dashboards.

Conclusion

Fringe Inspection brings unmatched in-situ inspection capabilities to the Renishaw 500Q metal additive manufacturing system, enabling manufacturers to capture high-fidelity, layer-by-layer data and take proactive control of build quality. As the only industrial-ready in-situ inspection product for additive manufacturing, the Fringe Inspection 500Q Kit is a powerful upgrade for any manufacturer using the machine.

The 500Q Kit is available now through the Phase3D online store. For technical questions, installation details, or integration support, contact sales@phase-3d.com.

About Phase3D

Phase3D is pioneering in-situ quality assurance for additive manufacturing with its Fringe Inspection™ product. By measuring every layer of a build in real-time, Phase3D provides actionable insights that help manufacturers reduce scrap, increase reliability, and scale additive manufacturing production with confidence. Learn more at https://www.phase-3d.com.

Share: