Fringe Inspection M290 Kit

Solve:

Spot:

Scan:

Log in to view pricing and add to cart.

Pairs well with

Fringe Inspection M290 Kit

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Product Details

Description

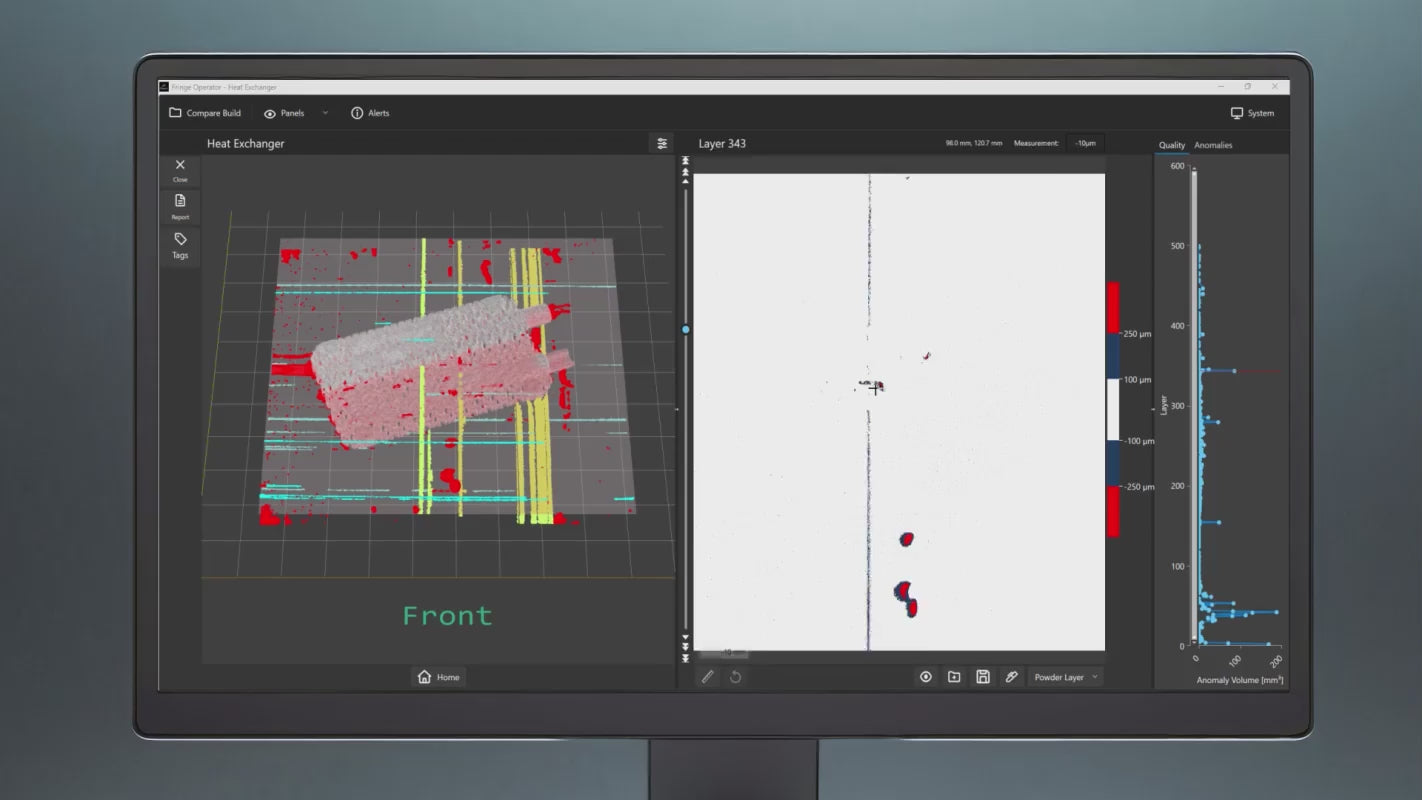

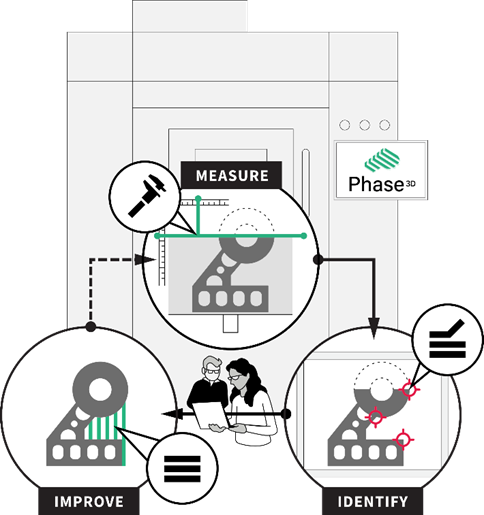

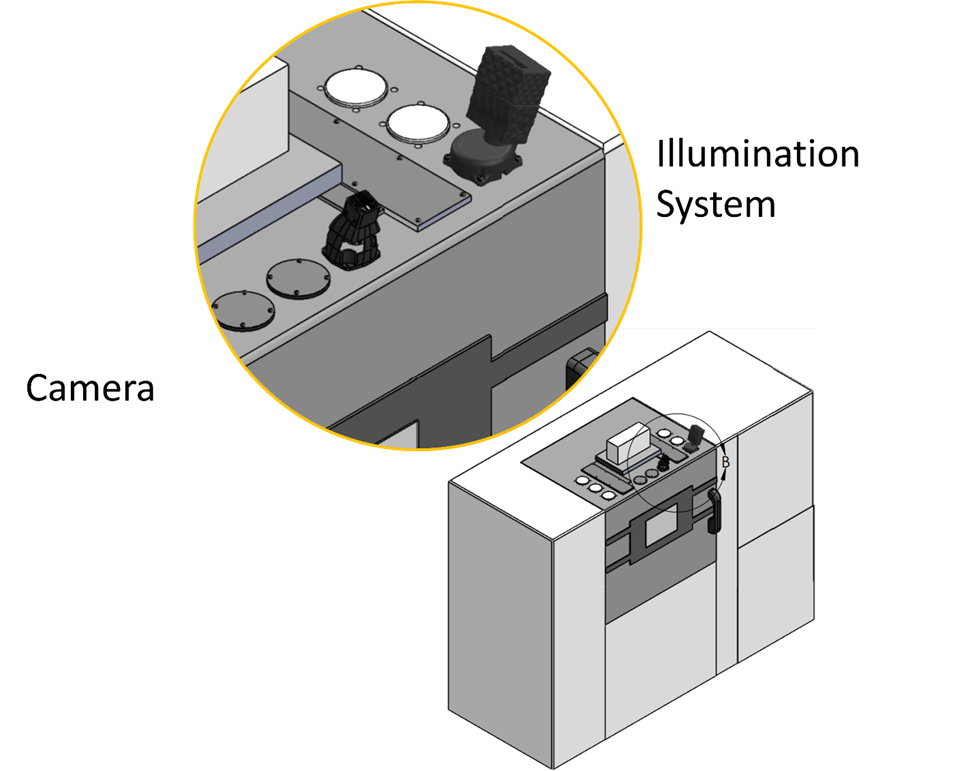

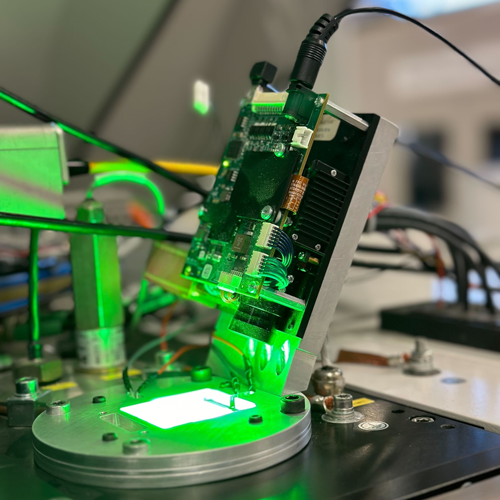

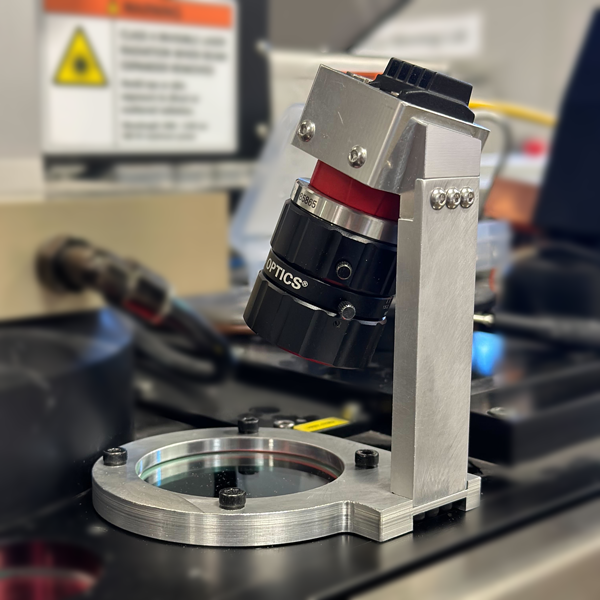

Measure every layer with a repeatable and calibratable inspection technology from Phase3D. Fringe Inspection outputs a proprietary heightmap of the additive manufacturing build process, quantifying anomalies in the process for real time decision making. Fringe Inspection is the only unit-based real-time inspection product for AM users to know what is happening inside of their machine. The product starts with Phase3D's Fringe Inspection Hardware Kits which are installed outside of the build chamber using available ports on your machine. The system is easily mounted onto most PBF or BJT printers.

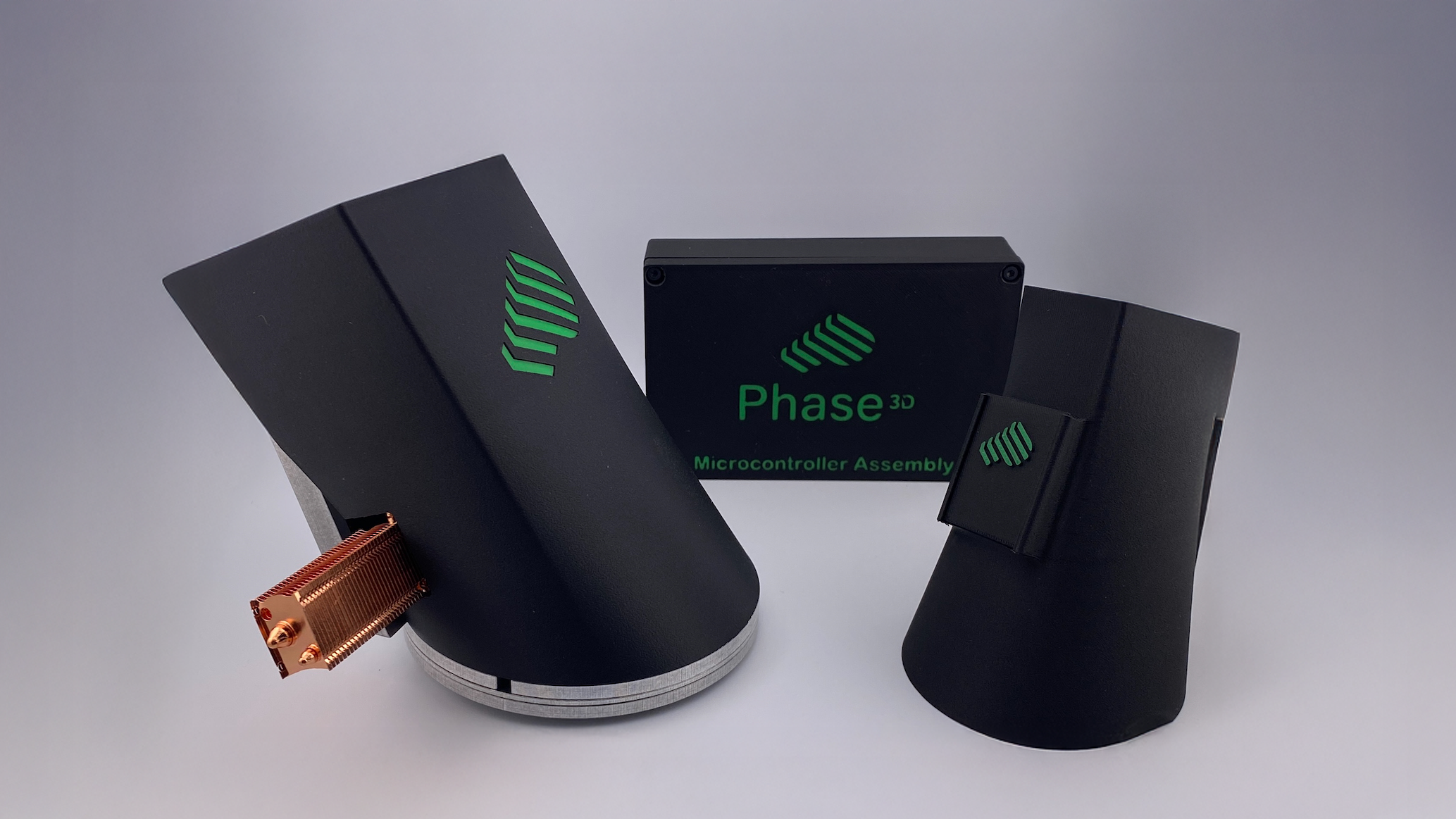

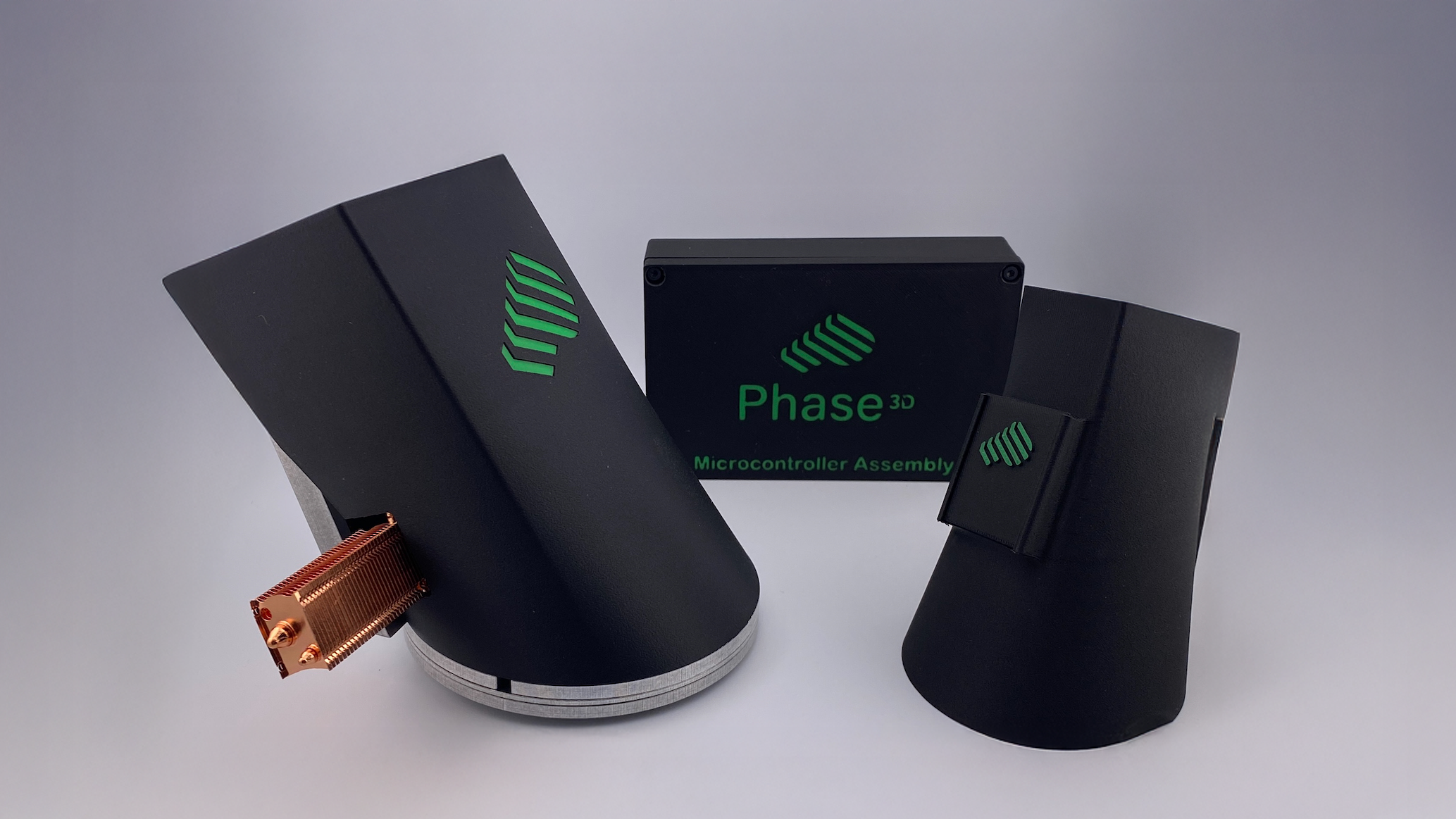

The EOS M290 Kit includes:

- 1x Camera Assembly;

- 1x Projector Assembly;

- 1x Microcontroller;

- 1x Computer;

- 1x Computer Accessory Set (monitor, keyboard, mouse, stand)

- 1-year Fringe Inspection Software Contract

Differentiator

Fringe Inspection is the only product on the market that outputs a unit-based, repeatable, calibratable, measurement with known uncertainty. The product relies on quantifiable measurement outputs to understand print quality to control the process on a micron scale.

Fringe Inspection does not rely on unreliable artificial intelligence (AI) models or machine learning to identify problems. Every anomaly is identified with a precise XY location and Z unit measurement. In addition to reliably and repeatably identifying anomalies in the process, the anomaly is quantified to control go/no-go criterial for every print.

Finally, Fringe Inspection stands apart from others in the market because of its scalable nature for number of machines or size of build plate. The product is easily scalable for your fleet of printers and can be controlled using Fringe Qualification. If higher resolution is needed for your production environment, Fringe Inspection can output higher resolution heightmaps easily than can be scaled for any size machine.

Specifications

Download the Fringe Inspection M290 Kit specifications to learn about the quality of measurements. System specifications can be modified depending on customers needs.

To access Phase3D heightmaps through Fringe Operator and gain all the features, including the 3D visualization, 2D deep dive analysis, and anomaly detection charts and tables, the remote computer must meet or exceed the following requirements:

- Windows 11

- NVIDIA RTX 2050 equivalent

or better

Contact us with any questions.

Fringe Inspection Hardware is Compatible With

FAQs

Please read our FAQs page to find out more.

Is Fringe Inspection cloud-based?

No. Fringe Inspection is an on-premises software where all data is processed locally.

How is Fringe Inspection data saved?

Data from Fringe Inspection is saved however the customer would prefer. Fringe Inspection data can be a fully air-gapped solution or linked to a cloud storage system depending on the customer's requirements.

What is installation like for Fringe Inspection?

Installing Fringe Inspection typically takes 24 calendar hours for installation, calibration, validation, and training. Typically our technician will arrive on-site mid-day and leave the following afternoon. If special requirements are required, we can work around your schedule.

What sized anomalies can Fringe Inspection identify?

Fringe Inspection can identify any variation in the powder or melted surface that is greater than 3-times the pixel size. For a standard installation Fringe Inspection can typically identify anomalies greater than 300 microns.