Fringe Inspection Renewal

Phase3D's Fringe Inspection renewal is now available online, making it easy to extend your license. Ongoing software updates and support included.

Pairs well with

Log in to view pricing and add to cart.

Fringe Inspection Renewal

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Product Details

Description

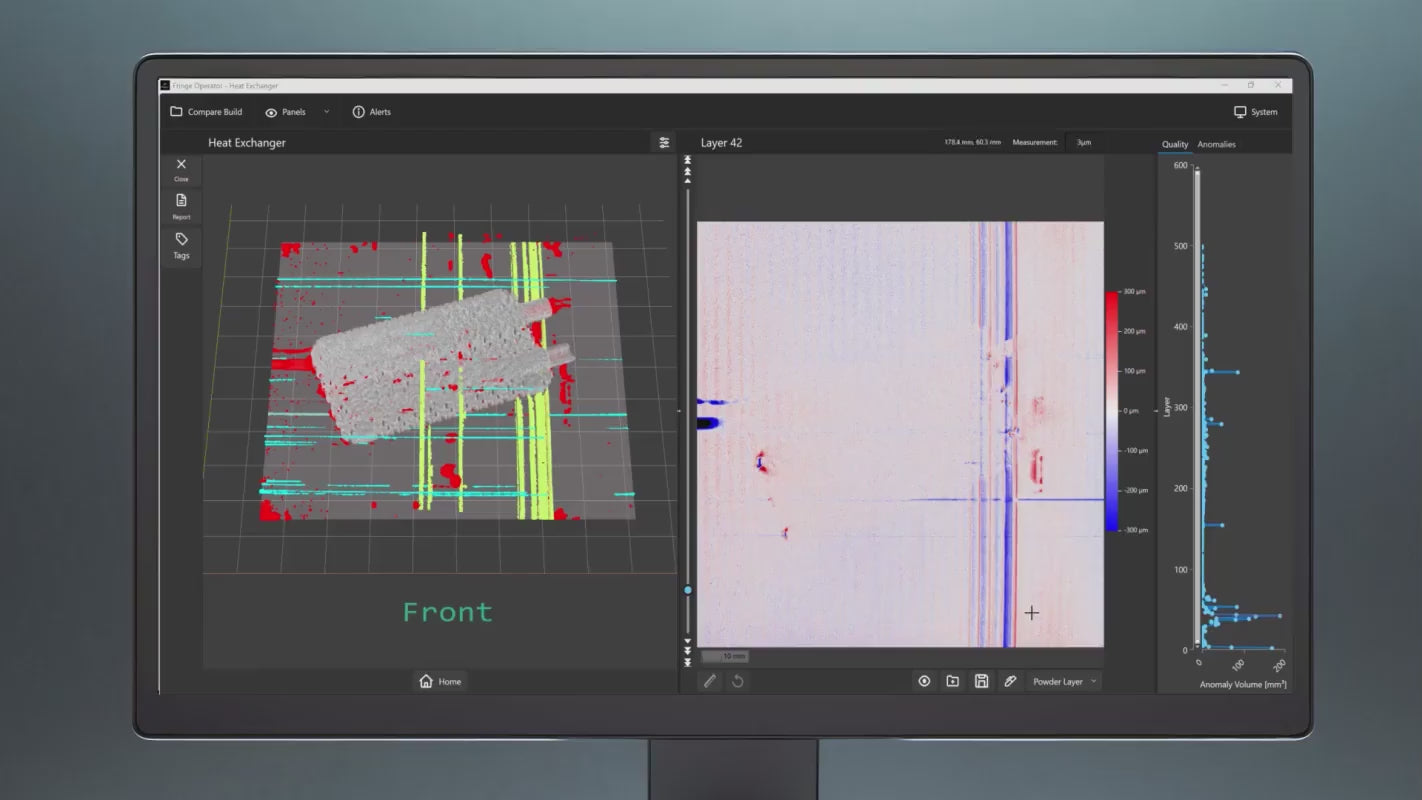

Renew your Fringe Inspection software license and maintain access to industry-leading layer-by-layer quality assurance for additive manufacturing. Phase3D's Fringe Inspection comprehensive software solution empowers engineers, designers, and managers with cutting-edge heightmap visualization and real-time analysis, helping detect defects early and ensure consistent build quality.

The Fringe Inspection Renewal includes both an on-machine and a remote Fringe Operator license, enabling powerful inspection capabilities directly on your 3D printer and from a remote workstation. With 24-hour technical support and ongoing software upgrades, your team stays equipped with the latest advancements in layer-by-layer inspection.

What's Included in Your Renewal:

- 1x On-Machine Fringe Operator License

- 1x Remote Fringe Operator License

- 24-hour Technical Support Response Time

- Access to Software Upgrades

Renewing your license is easy—purchase your Fringe Inspection Renewal directly through our online store and continue driving excellence in additive manufacturing.

Differentiator

Fringe Inspection is the only in-situ inspection product on the market that delivers unit-based, repeatable, and calibratable measurements with known uncertainty, enabling true quantitative process control at the micron scale.

Unlike traditional methods that depend on unreliable artificial intelligence (AI) or machine learning models, Fringe Inspection can precisely detect and locate anomalies with exact XY coordinates and Z-height measurements. Every anomaly is not only detected but also quantified, allowing manufacturers to establish reliable go/no-go criteria for every 3D print.

Fringe Inspection is engineered for scalability, whether you're monitoring a single machine or managing a full fleet. The system adapts to varied build plate sizes and machine configurations, delivering consistent, high-resolution heightmaps that support data-driven process control. For environments requiring higher resolution, Fringe Inspection can output enhanced heightmaps, scalable across any printer or platform.

Integrated with Fringe Qualification, Fringe Inspection enables centralized management and fleet-wide quality oversight, making it the most scalable and precise solution for additive manufacturing monitoring.

Fringe Inspection Hardware is Compatible With

FAQs

Please read our FAQs page to find out more.

Is Fringe Inspection cloud-based?

No. Fringe Inspection is an on-premises software where all data is processed locally.

How is Fringe Inspection data saved?

Data from Fringe Inspection is saved however the customer would prefer. Fringe Inspection data can be a fully air-gapped solution or linked to a cloud storage system depending on the customer's requirements.

What is installation like for Fringe Inspection?

Installing Fringe Inspection typically takes 24 calendar hours for installation, calibration, validation, and training. Typically our technician will arrive on-site mid-day and leave the following afternoon. If special requirements are required, we can work around your schedule.

What sized anomalies can Fringe Inspection identify?

Fringe Inspection can identify any variation in the powder or melted surface that is greater than 3-times the pixel size. For a standard installation Fringe Inspection can typically identify anomalies greater than 300 microns.