The U.S. Department of Energy (DOE) has recognized Phase3D’s pioneering work in additive manufacturing, led by founder and CEO Niall O’Dowd. In collaboration with Argonne National Laboratory, Phase3D developed a real-time, in-process inspection system for industrial 3D printers that delivers actionable part quality data—helping manufacturers reduce material waste, energy usage, and production delays.

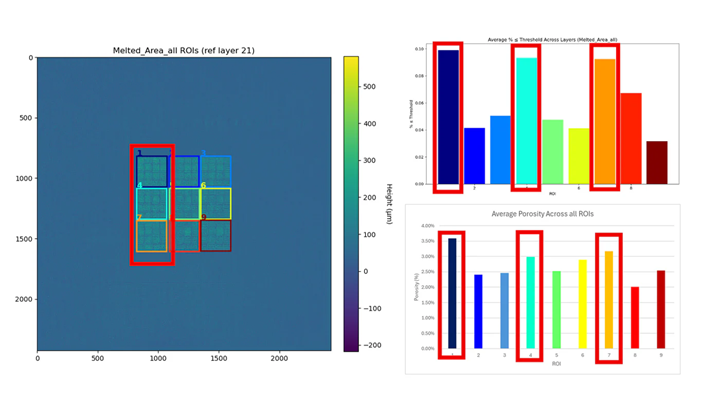

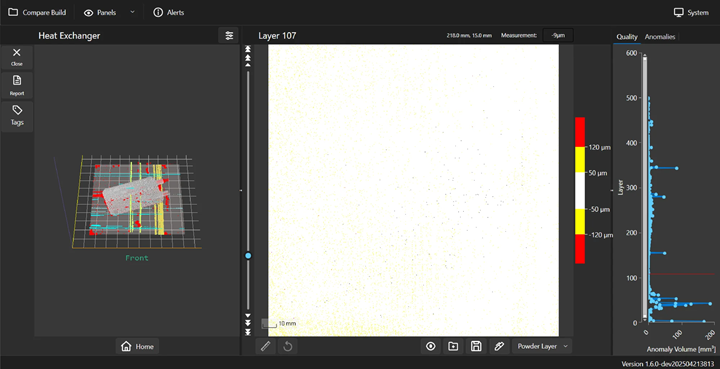

This technology detects anomalies as small as 15 microns during the printing process, enabling early intervention and significantly lowering part rejection rates. Unlike many existing systems, Phase3D’s solution is OEM-agnostic, making it accessible and scalable across the industry.

Key project achievements:

-

Developed and tested a real-time monitoring system on the Renishaw AM400.

-

Used Advanced Photon Source data to link powder bed defects with part porosity.

-

Built adaptable hardware for printers outside of Argonne.

As AM shifts from prototyping to full-scale production, reliable quality assurance is essential—especially for critical applications in aerospace, medical, and nuclear industries. Phase3D’s system supports that transition while also promoting sustainability by cutting down material waste by up to 15%, translating to significant emissions reductions.

Read the full DOE report: https://rb.gy/cxqgea

Share: