Phase3D is proud to be featured by Argonne National Laboratory for our collaboration through the Chain Reaction Innovations (CRI) program. In partnership with Argonne materials scientist Dr. Xuan Zhang, we’re transforming how structural defects in metal additive manufacturing are detected—before parts even leave the print bed.

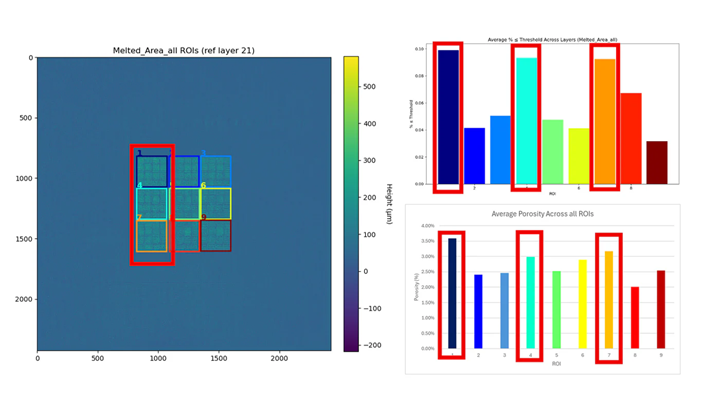

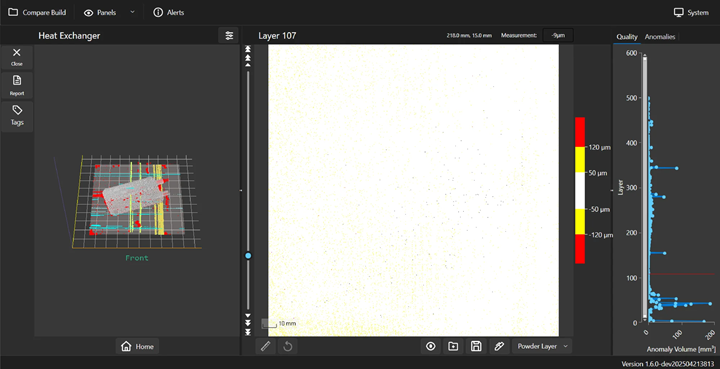

Our team at Phase3D developed a novel in-situ inspection technology that uses structured light to measure the height of each printed layer. This approach enables manufacturers to identify and address defects in real-time, rather than after a build is complete. The result: improved part quality, reduced material waste, and a significant decrease in greenhouse gas emissions.

Through CRI and support from the Department of Energy’s Lab-Embedded Entrepreneurship Program, we've been able to collaborate directly with national lab scientists, access world-class resources, and further our mission of enabling sustainable and reliable additive manufacturing.

Read the full Argonne article: https://rb.gy/how2rd

Share: