Advancing Binder Jetting Additive Manufacturing with Fringe Research Technology

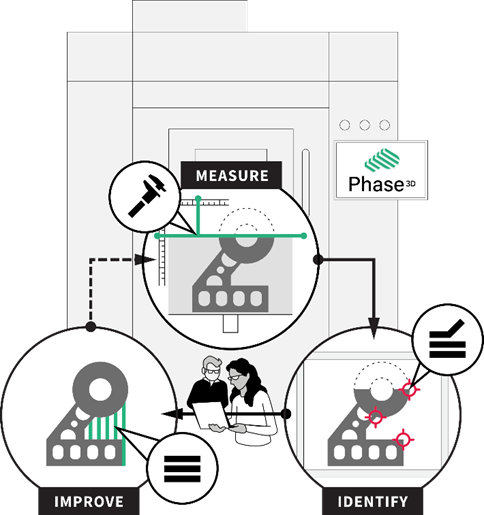

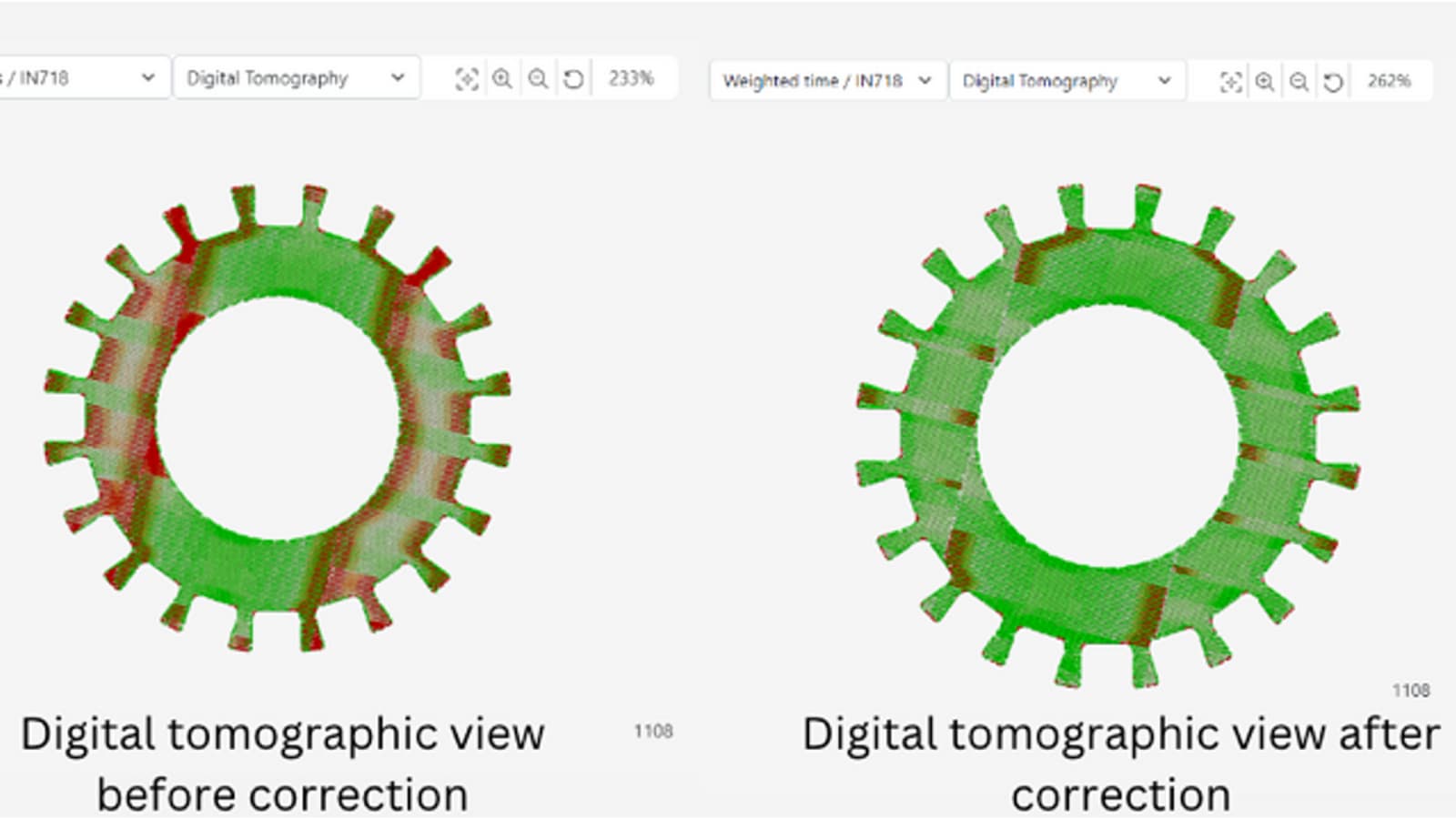

Advancing AM Quality and Reliability

Additive Insight: How Phase3D is Advancing In-Process Quality Monitoring

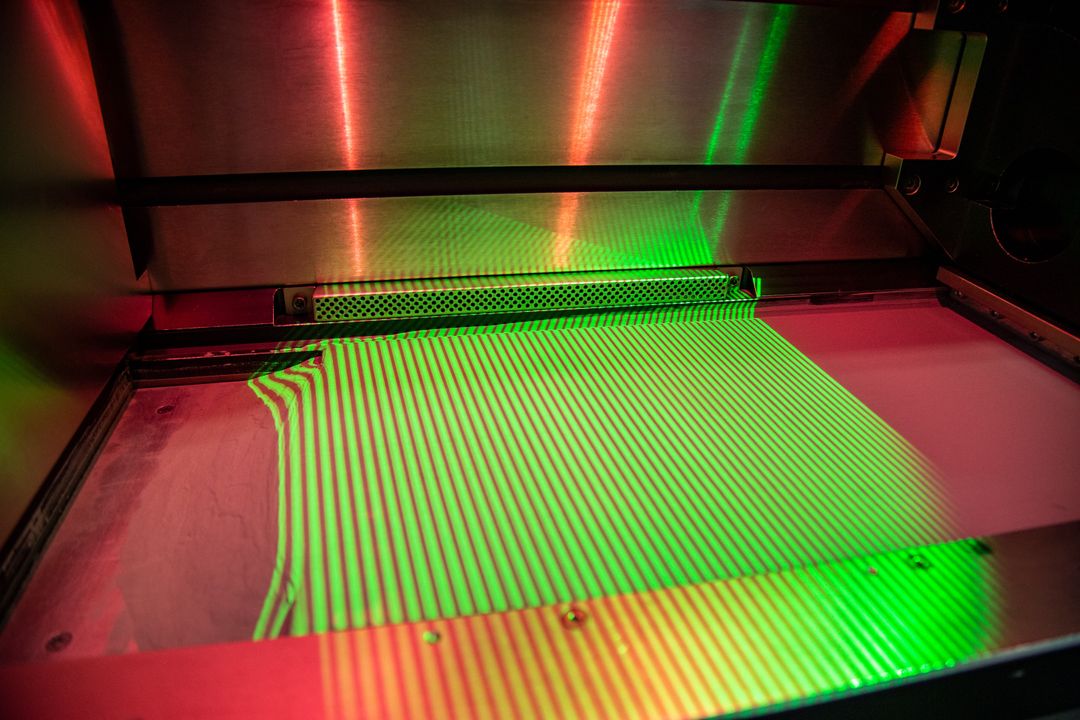

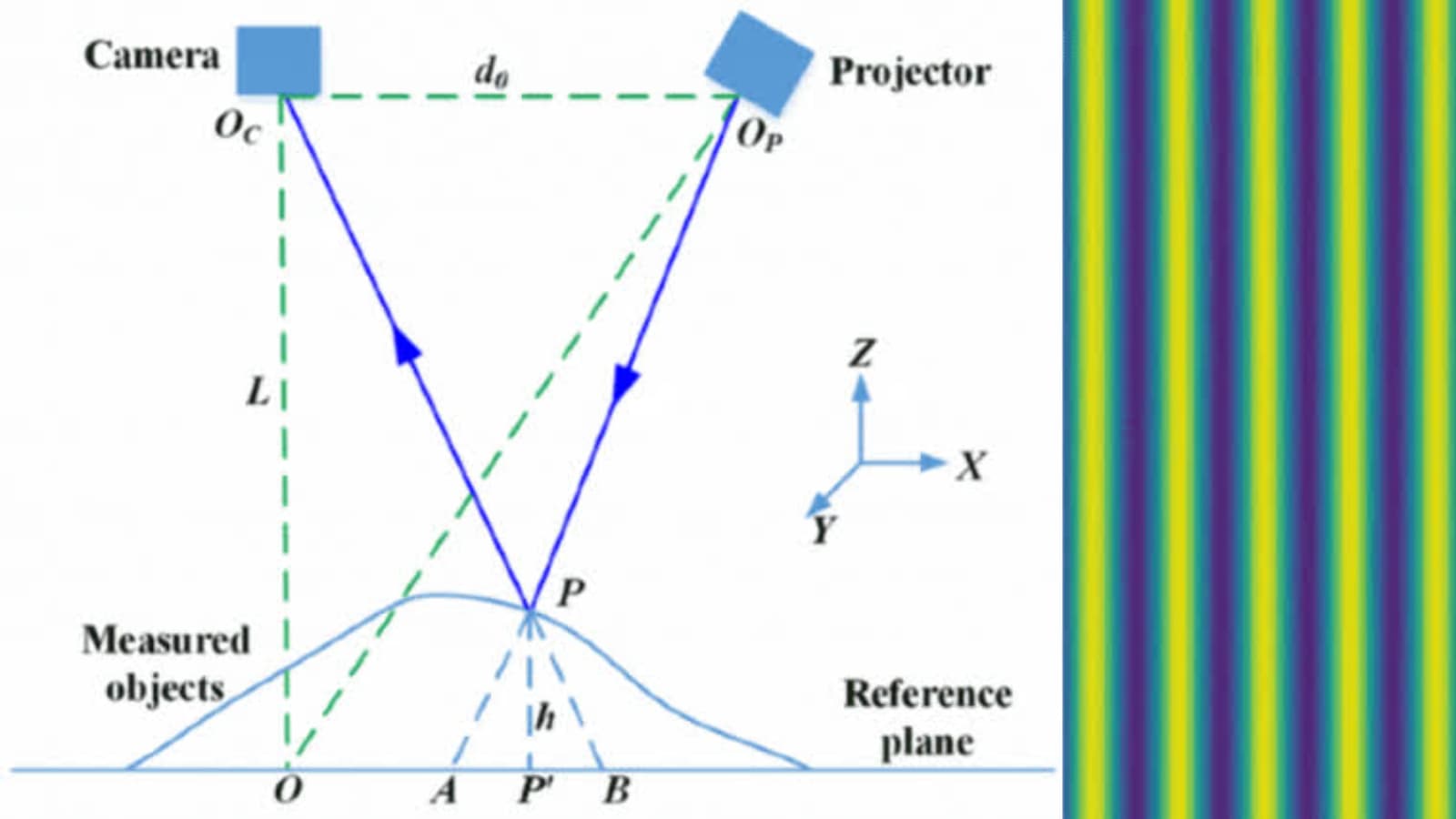

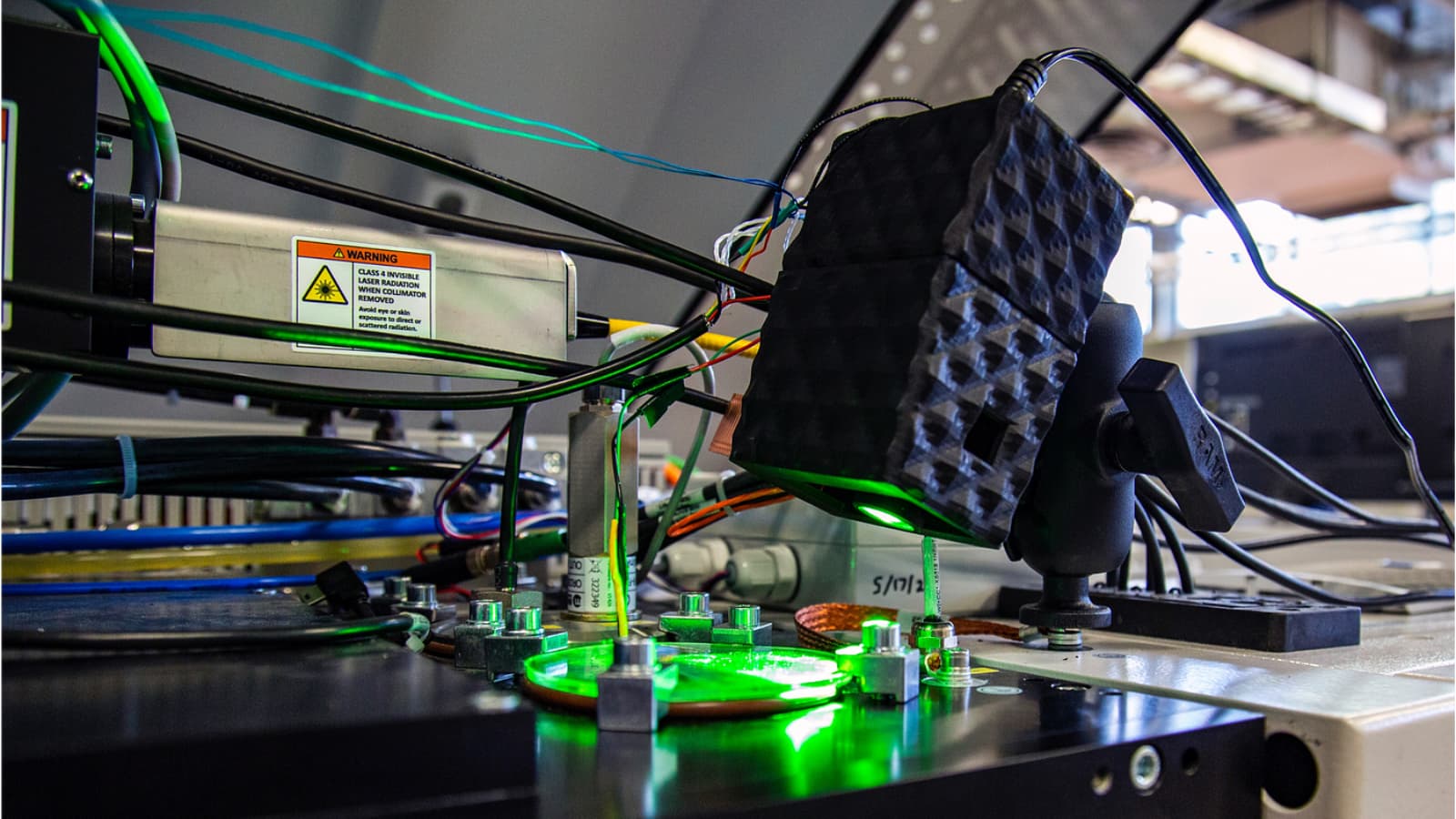

What is Fringe Projection? The Backbone to Objective Measurements by Phase3D.

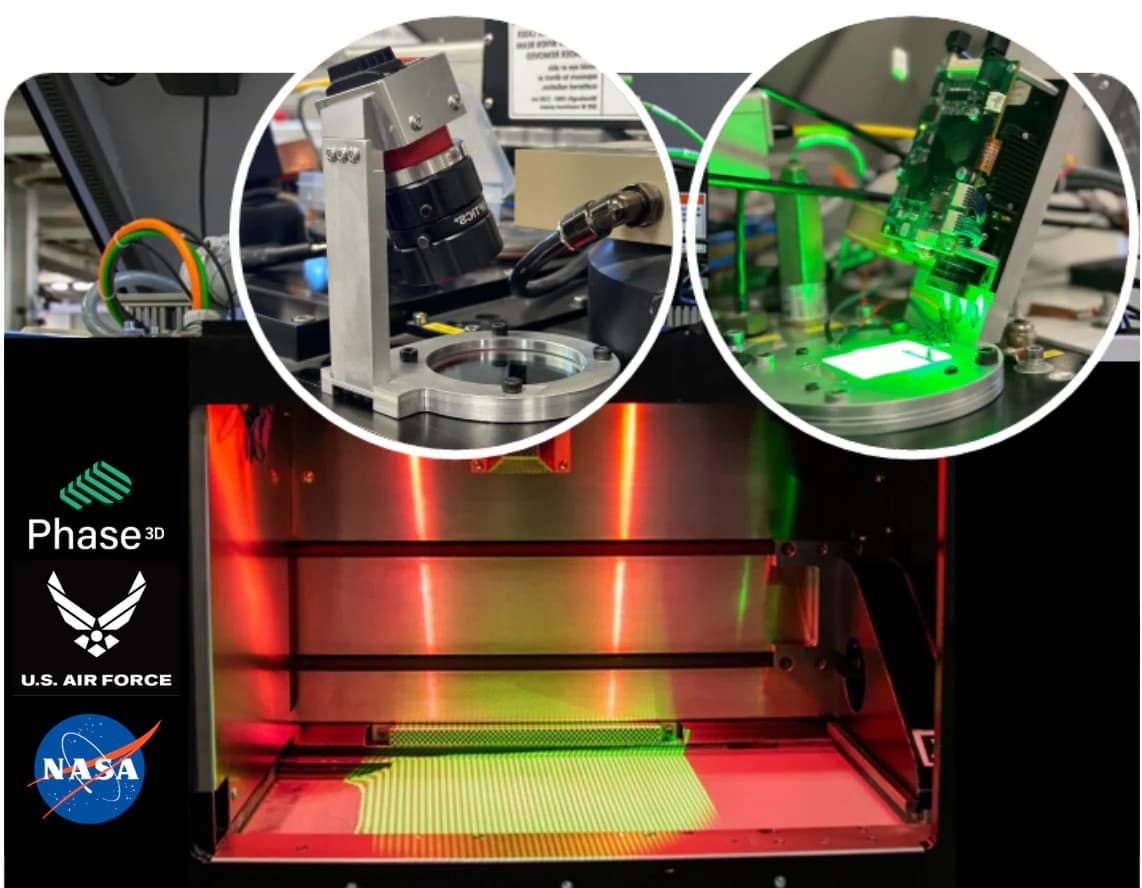

Phase3D Develops Real-Time Inspection for Air Force Additive Manufacturing

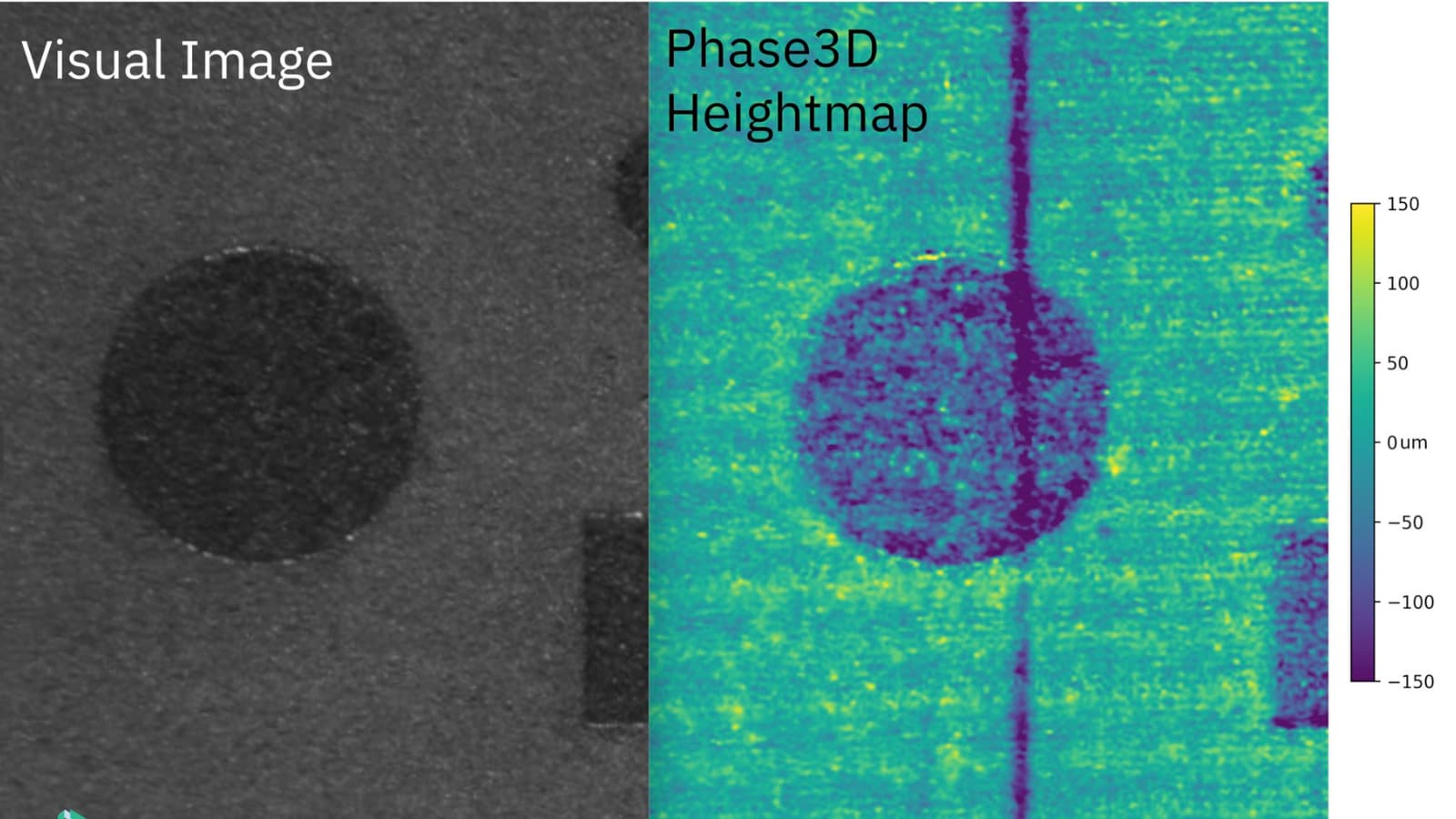

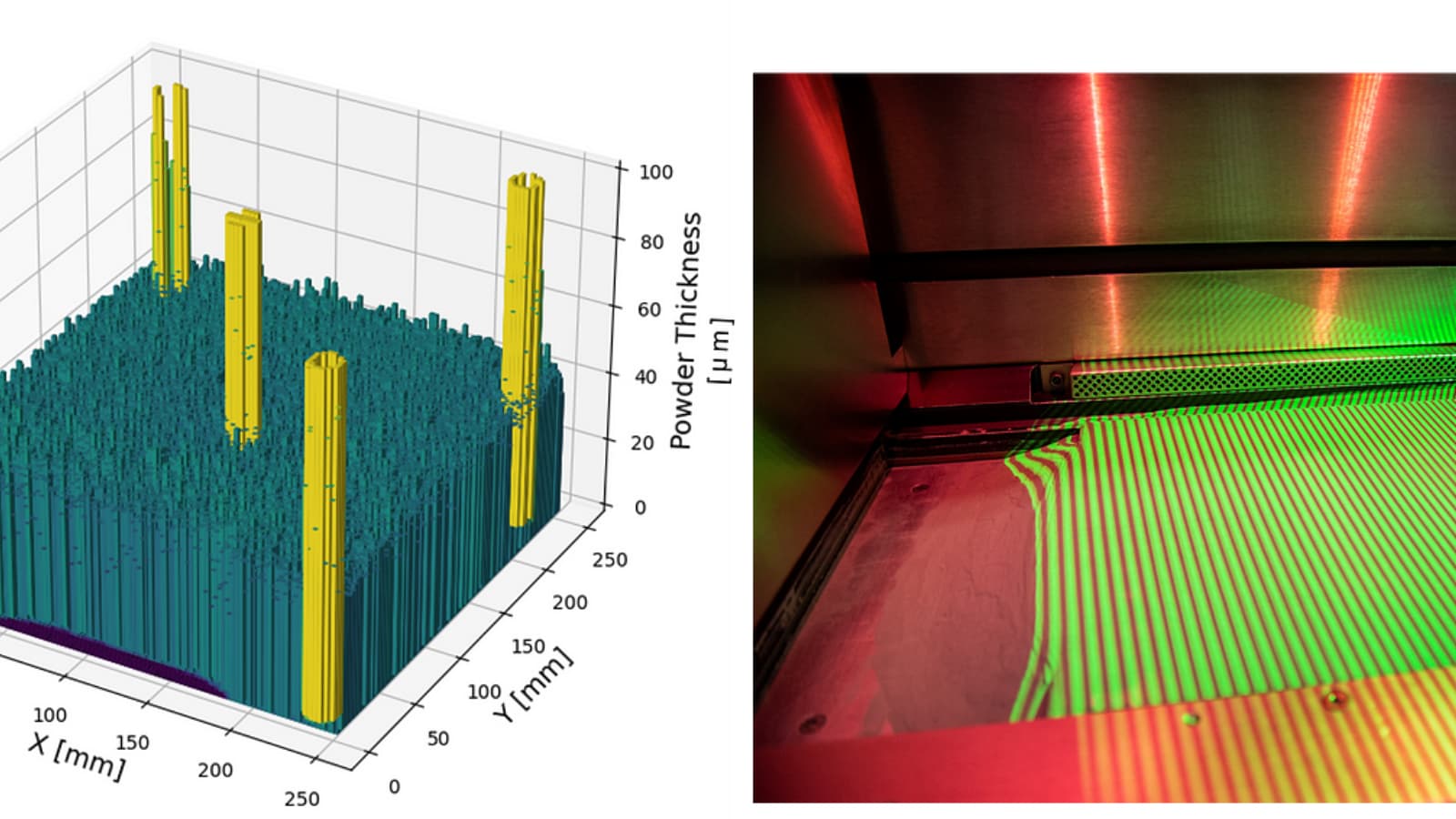

Phase3D Introduces Advanced Layer Thickness Measurement

What It Takes to Build a Startup: Niall O’Dowd on 3Degrees Discussions

Behind the Build: Niall O’Dowd Talks AM Innovation on the 3Degrees Podcast

Phase3D Secures $1.25M US Air Force Contract for Cold Spray Additive

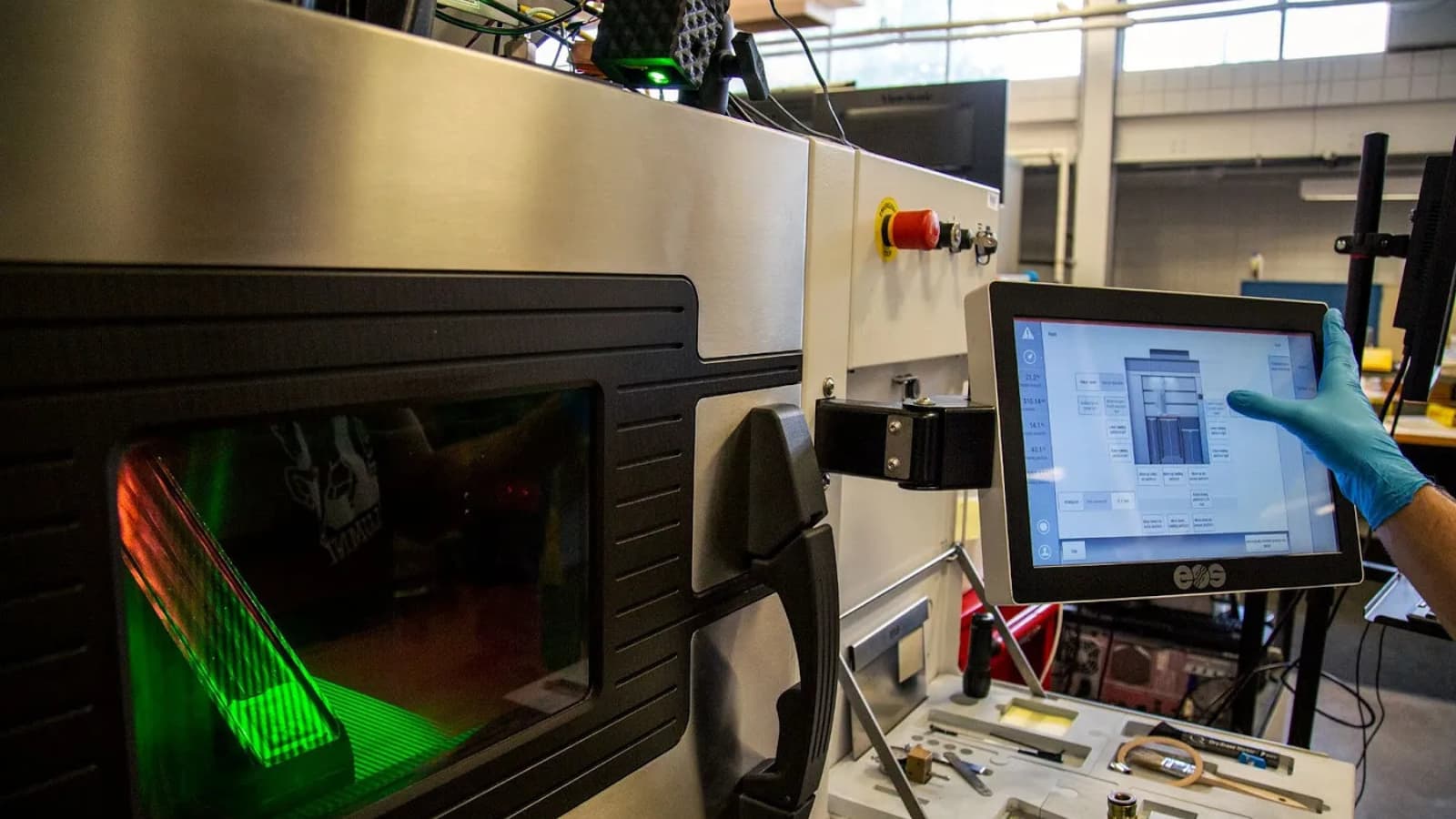

Phase3D and DMG MORI Launch Research Collaboration

Phase3D and 1000Kelvin Win US Air Force STTR Contract

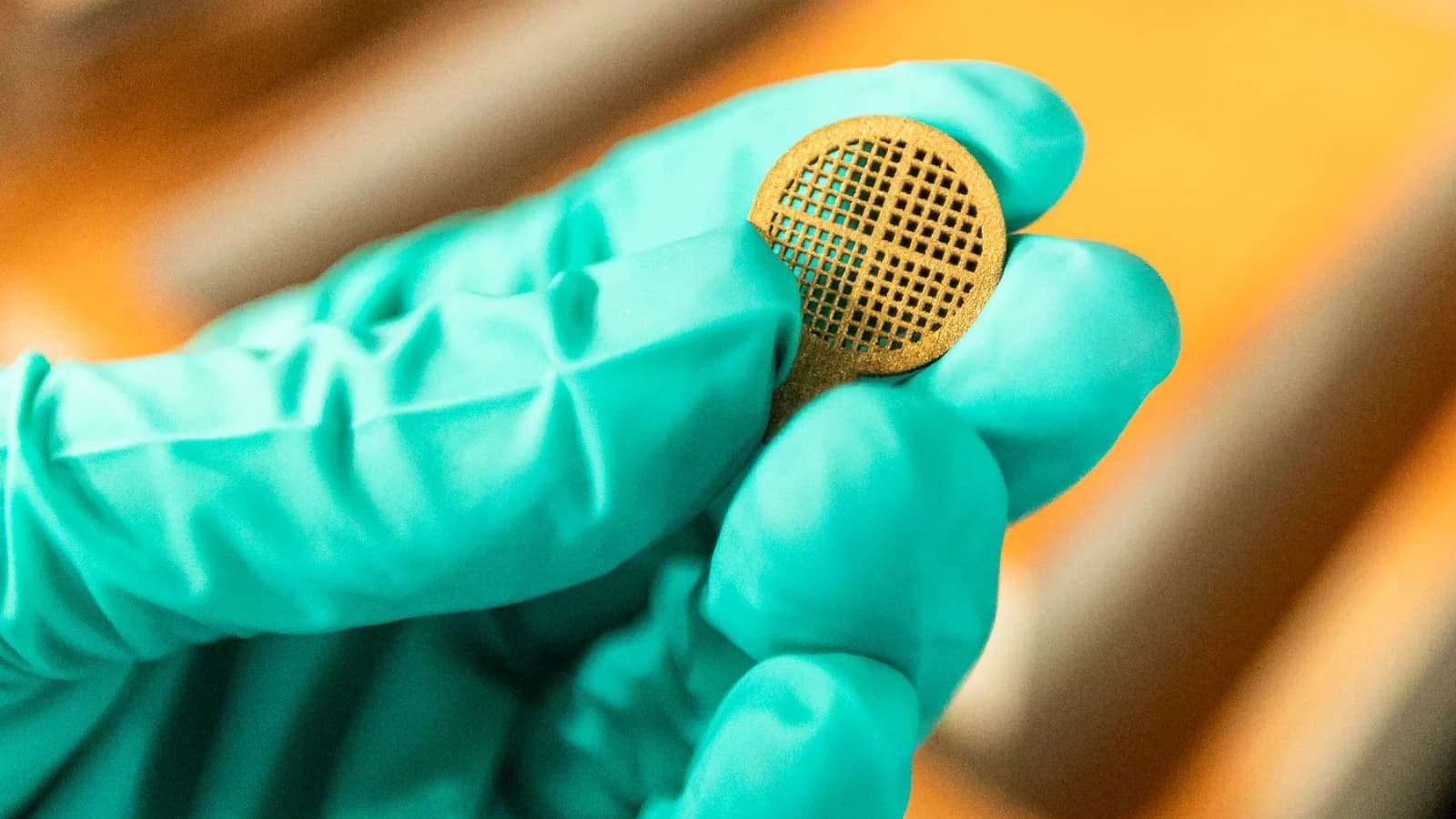

Bringing Precision and Sustainability to Nuclear 3D Printing

Partnering for Precision: Phase3D and Argonne National Laboratory Advance Metal 3D Printing

Phase3D Partners with Materialise

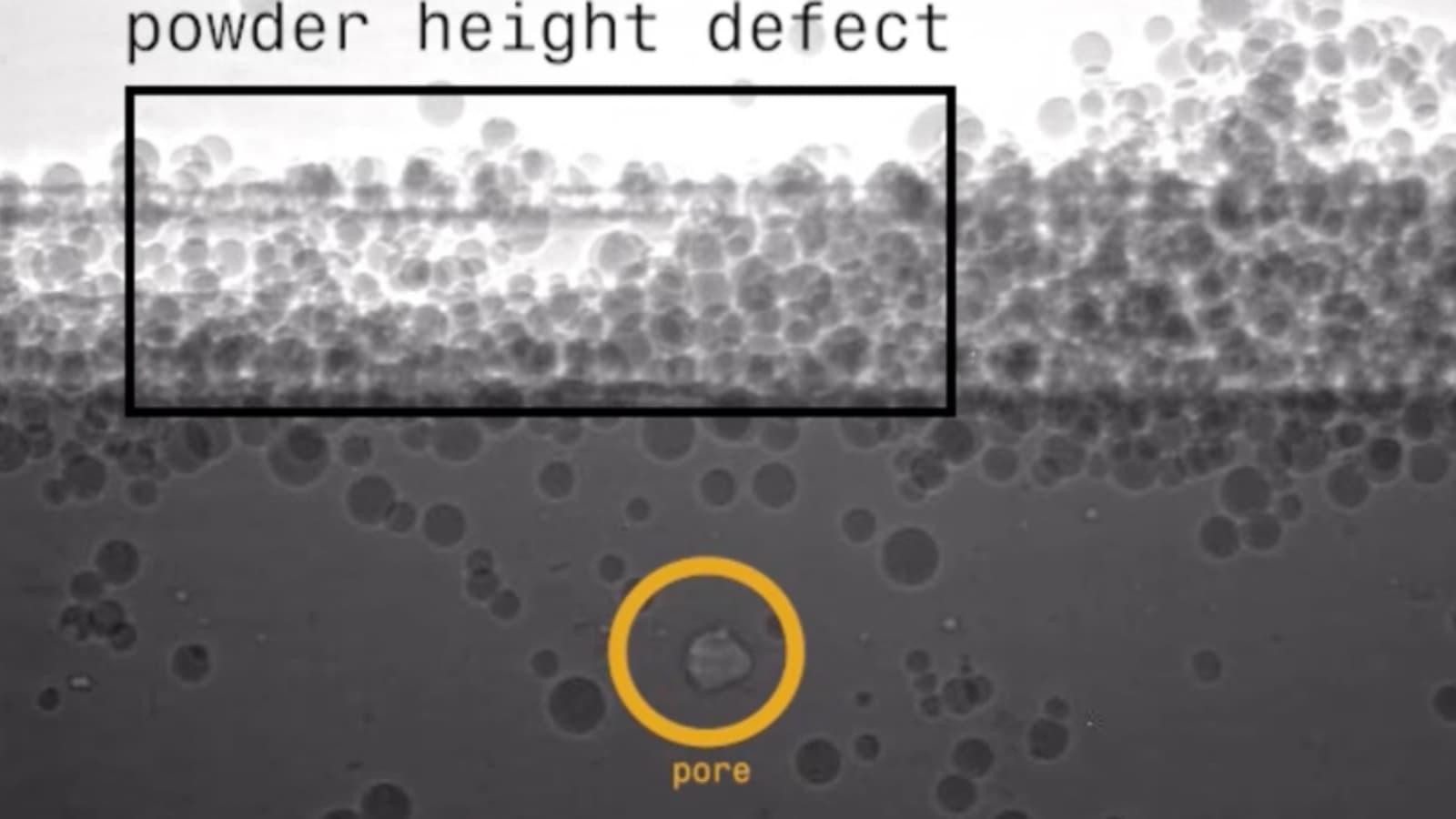

Linking Height Irregularities to Gas Porosity via Synchrotron X-rays

Phase3D Launches Early Adopter Program for 3D Printing Inspection

Phase3D Completes Collaboration with Oak Ridge National Lab

Phase3D Wins Air Force Innovation Open Call

Additive Monitoring Systems is now Phase3D

NASA Selects Additive Monitoring Systems for In-Situ Manufacturing

Driving Sustainable Innovation in Additive Manufacturing with the U.S. Department of Energy

US Air Force Contracts Chicago Startup for Additive Manufacturing Monitoring