Phase3D Releases Two Large-Format Fringe Inspection Systems for Metal Additive Manufacturing

Phase3D today announced the release of two new large-format Fringe Inspection™ Systems for metal additive manufacturing. The new systems, Large Format Fringe Inspection™ and Large Format Fringe Inspection™ Hi-Rez, extend Phase3D’s in-situ inspection technology to support the EOS M 400 series of printers and other large-format platforms such as the Nikon SLM NXG product line.

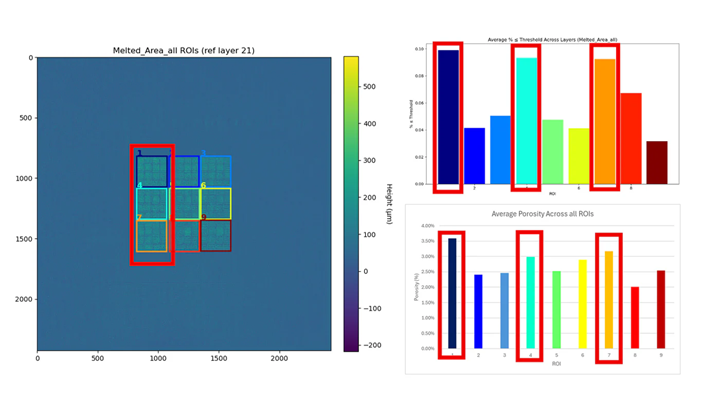

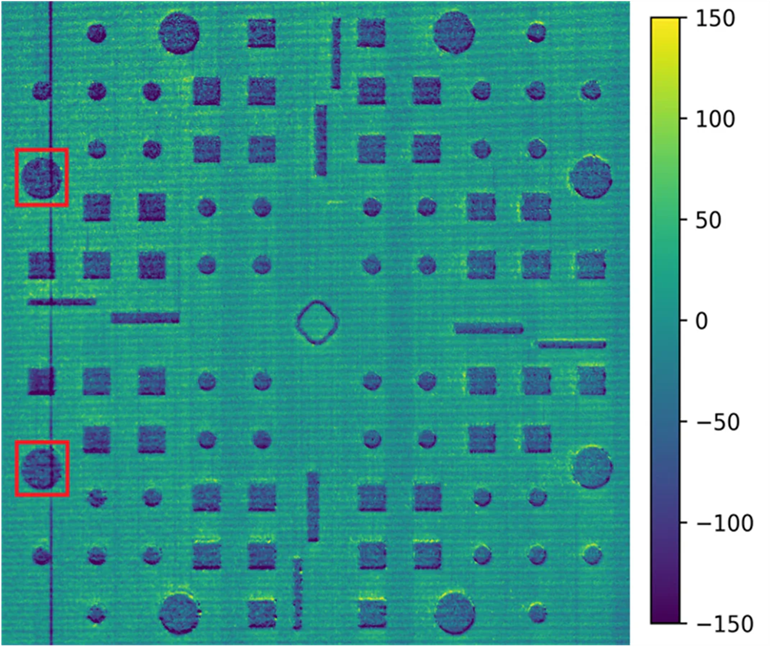

Spatter Detection: How Fringe Inspection Links Surface Measurements to Porosity in Metal AM

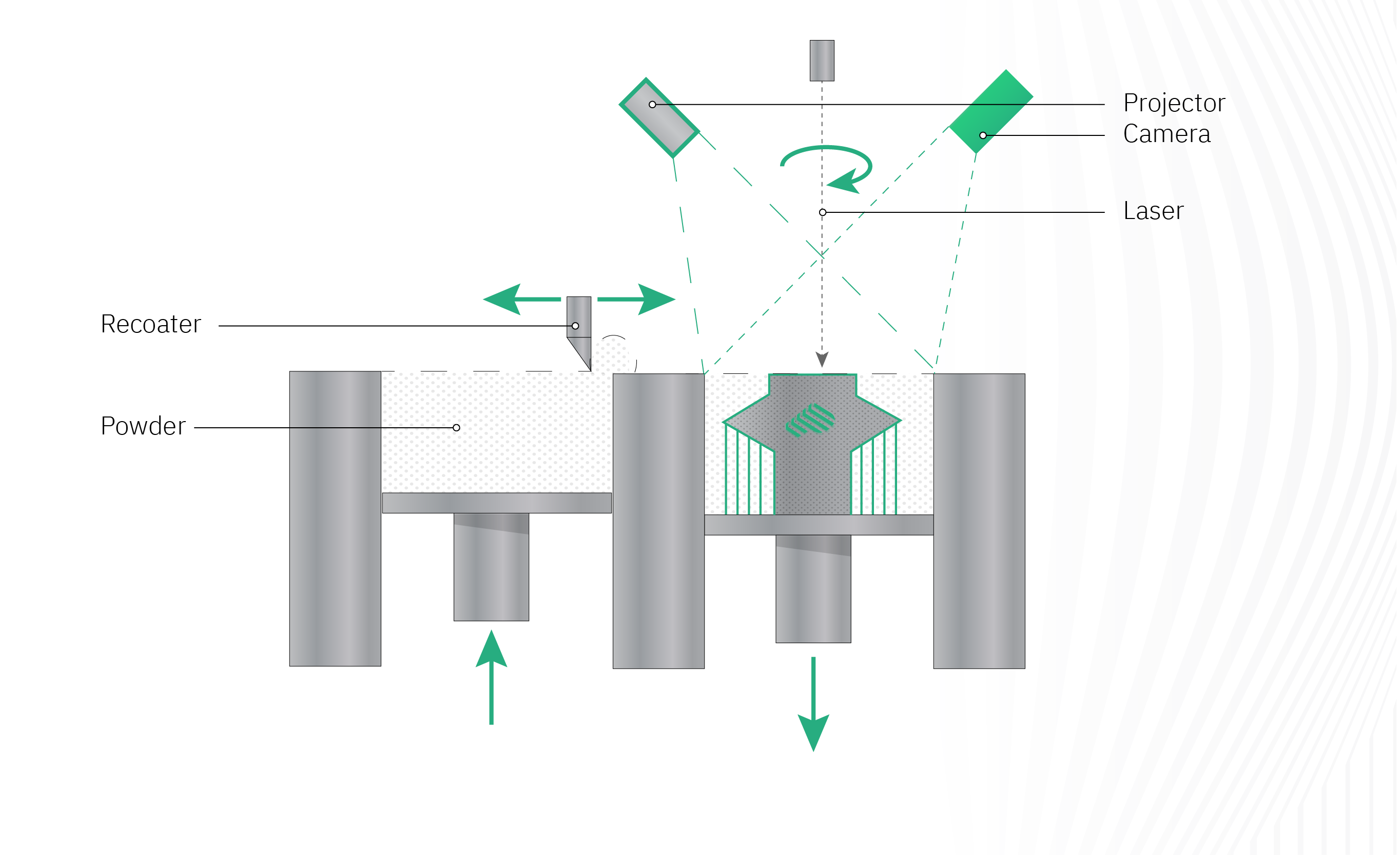

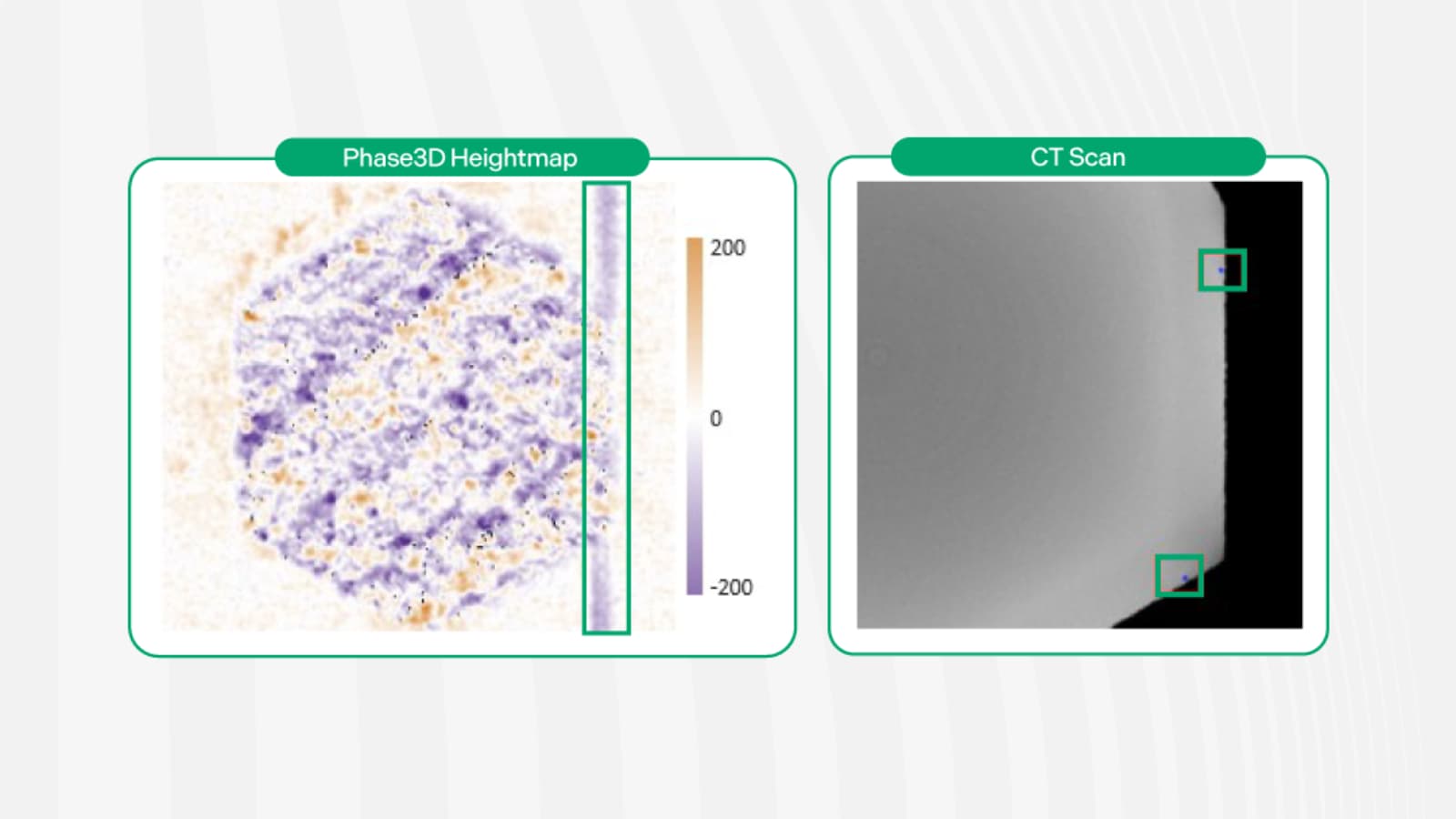

Discover how Phase3D’s Fringe Inspection™ technology revolutionises spatter detection in metal additive manufacturing (AM) by linking surface roughness measurements to porosity. Unlike traditional camera-based or AI-driven monitoring, Fringe Inspection delivers quantitative, traceable, micron-accurate data, revealing how gas flow inefficiencies and energy density affect part quality.

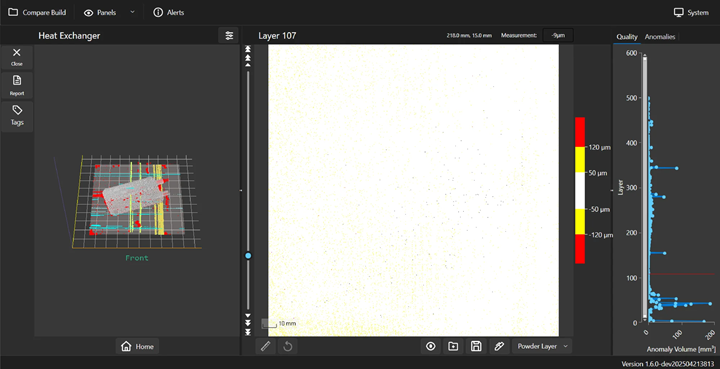

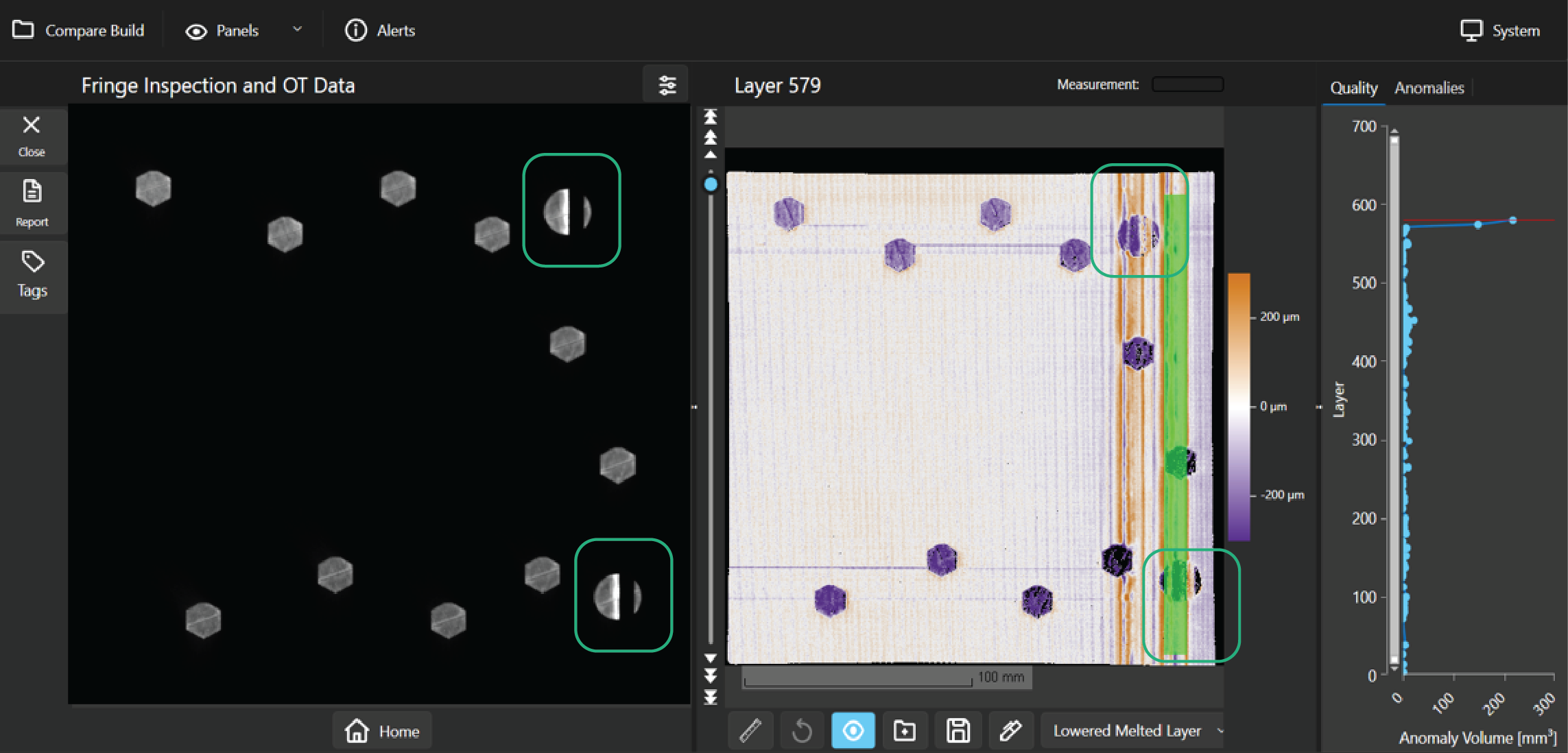

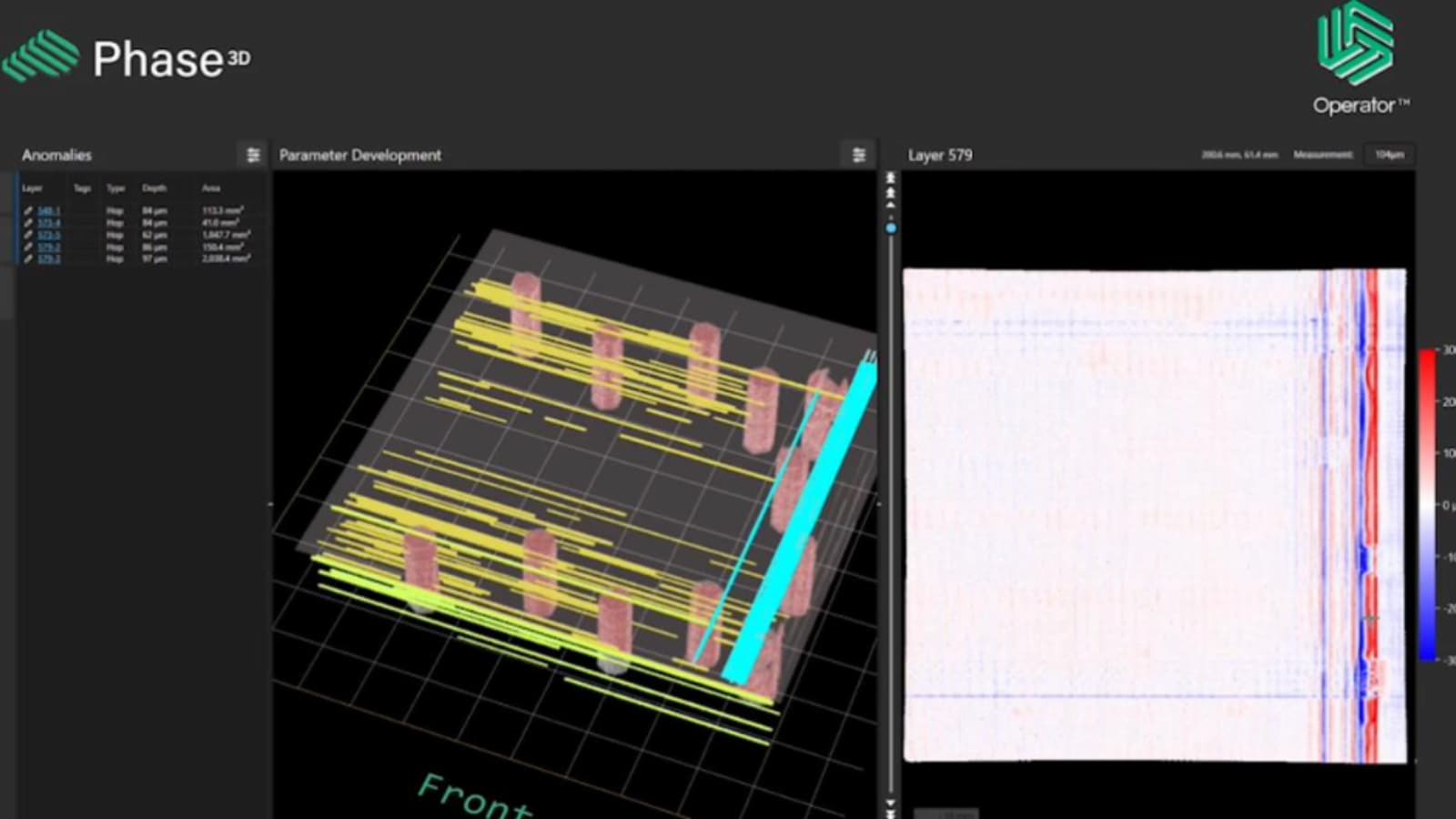

Streamlining Additive Manufacturing Quality Review with Objective, Measurable Thresholds

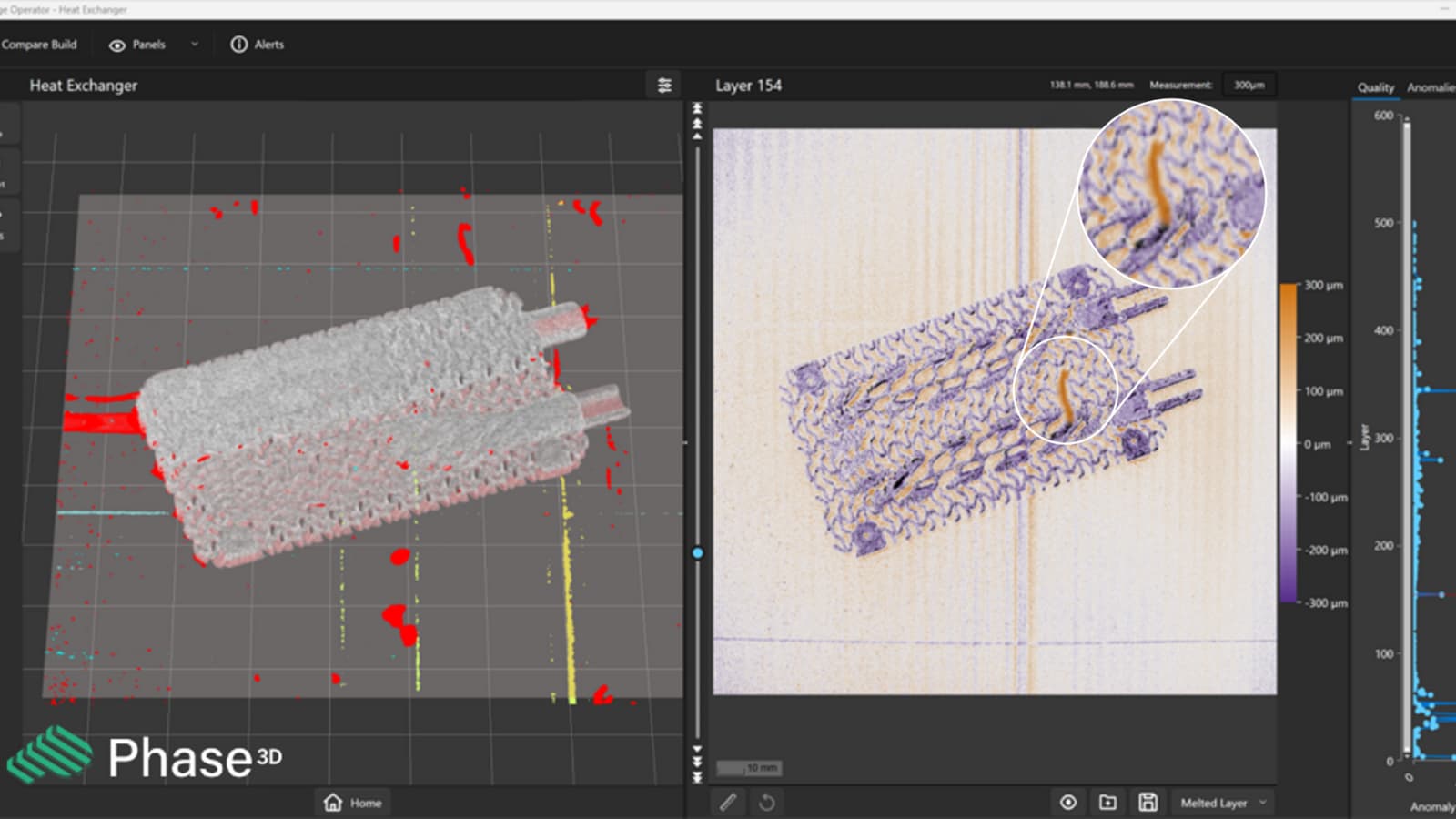

Accelerating Additive Manufacturing Quality Reviews with Fringe Operator™

In high-volume additive manufacturing, inspecting thousands of build layers for anomalies is a major bottleneck. One manufacturer using Phase3D’s Fringe Inspection cut review times by over 70% by combining Quality Chart anomaly visualisation with Adjustable Colorbars.

Missed the Customer Panel? Watch the Webinar On-Demand

Discover how leading manufacturers are using Phase3D’s Fringe Inspection™ to improve additive manufacturing outcomes in this on-demand customer panel webinar. Featuring real-world insights from Elementum 3D, Alloyed, and CCAM, the session explores how in-situ heightmap data is transforming production monitoring, reducing scrap, and ensuring part quality in real-time.

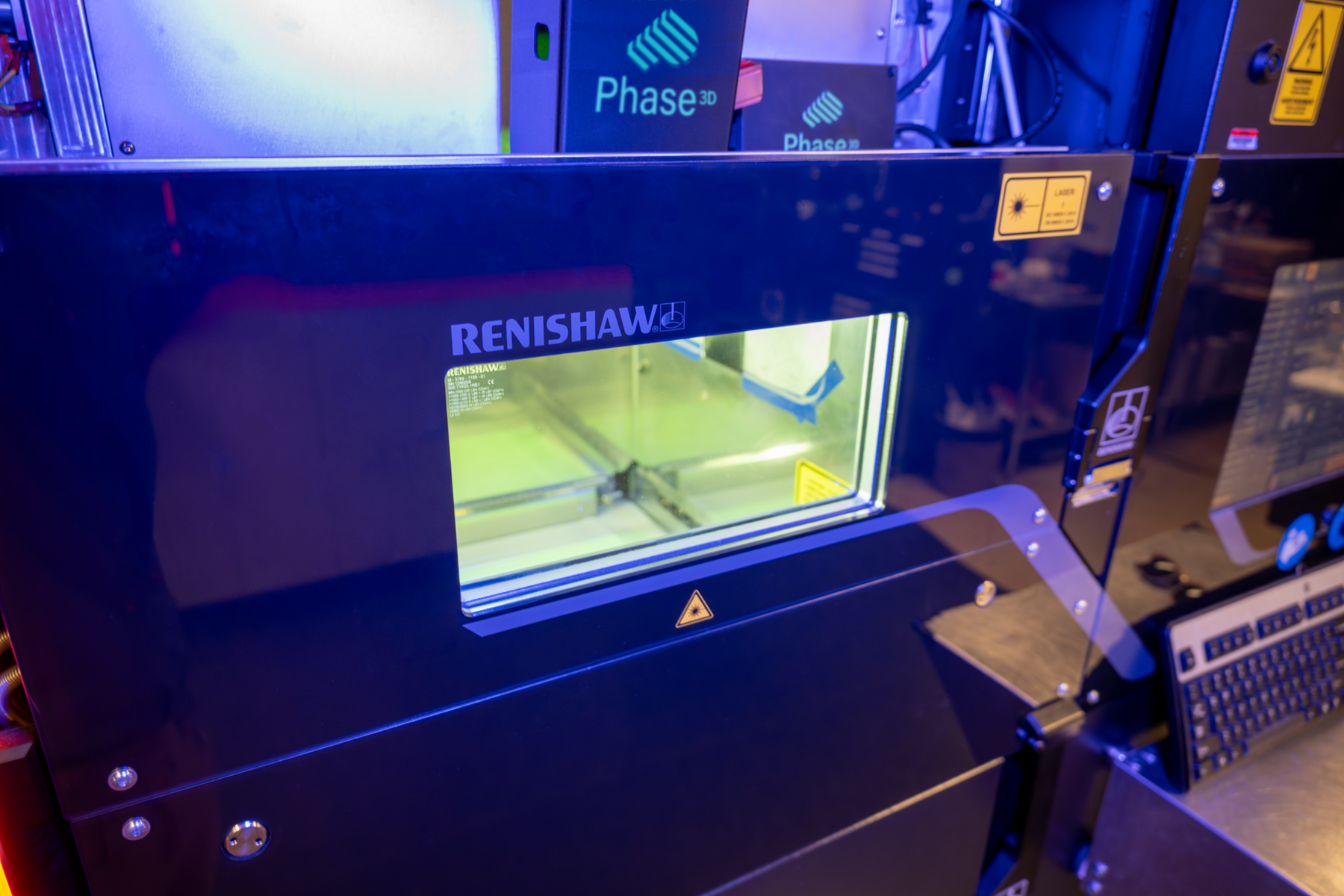

Fringe Inspection™ Now Available for Renishaw 500Q

Combining Thermal and Geometric Monitoring to Improve Aerospace AM Quality

Phase3D Named Finalist in ASTRO America’s In- Situ Awareness Challenge

Advancing Metal Additive Manufacturing with Fringe Inspection™ by Phase3D

Correlating Build Anomalies to Defects in Aerospace Additive Manufacturing with Fringe Inspection™

Phase3D Launches Online Store to Streamline Access to Fringe Inspection™ for Additive Manufacturing

Fringe Inspection™ Installed at HRL Laboratories for Groundbreaking SPARES Project

Couldn’t attend the webinar live? You can now watch it on demand!

Ensuring Build Consistency in Serial AM Production with Fringe Inspection™

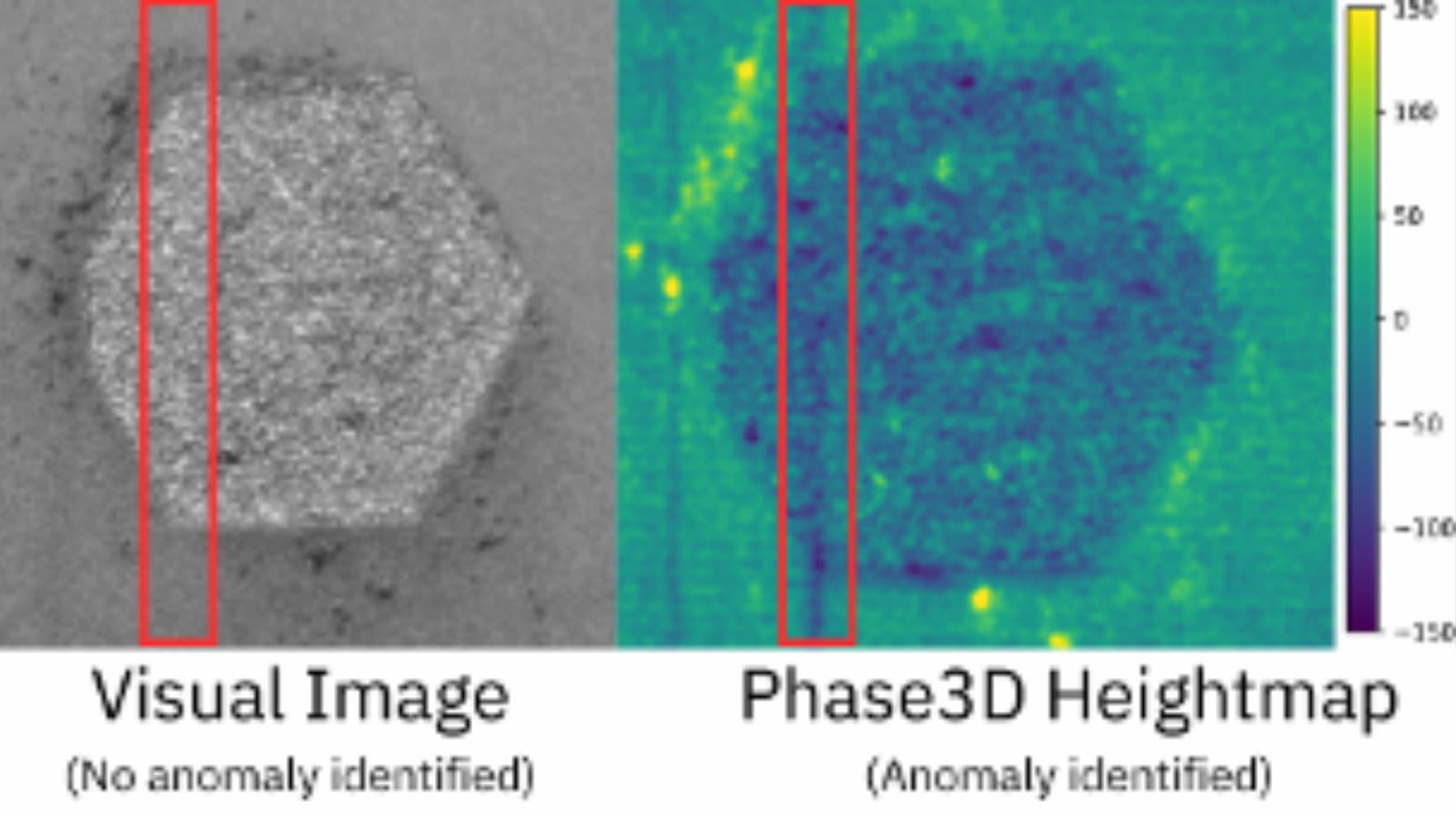

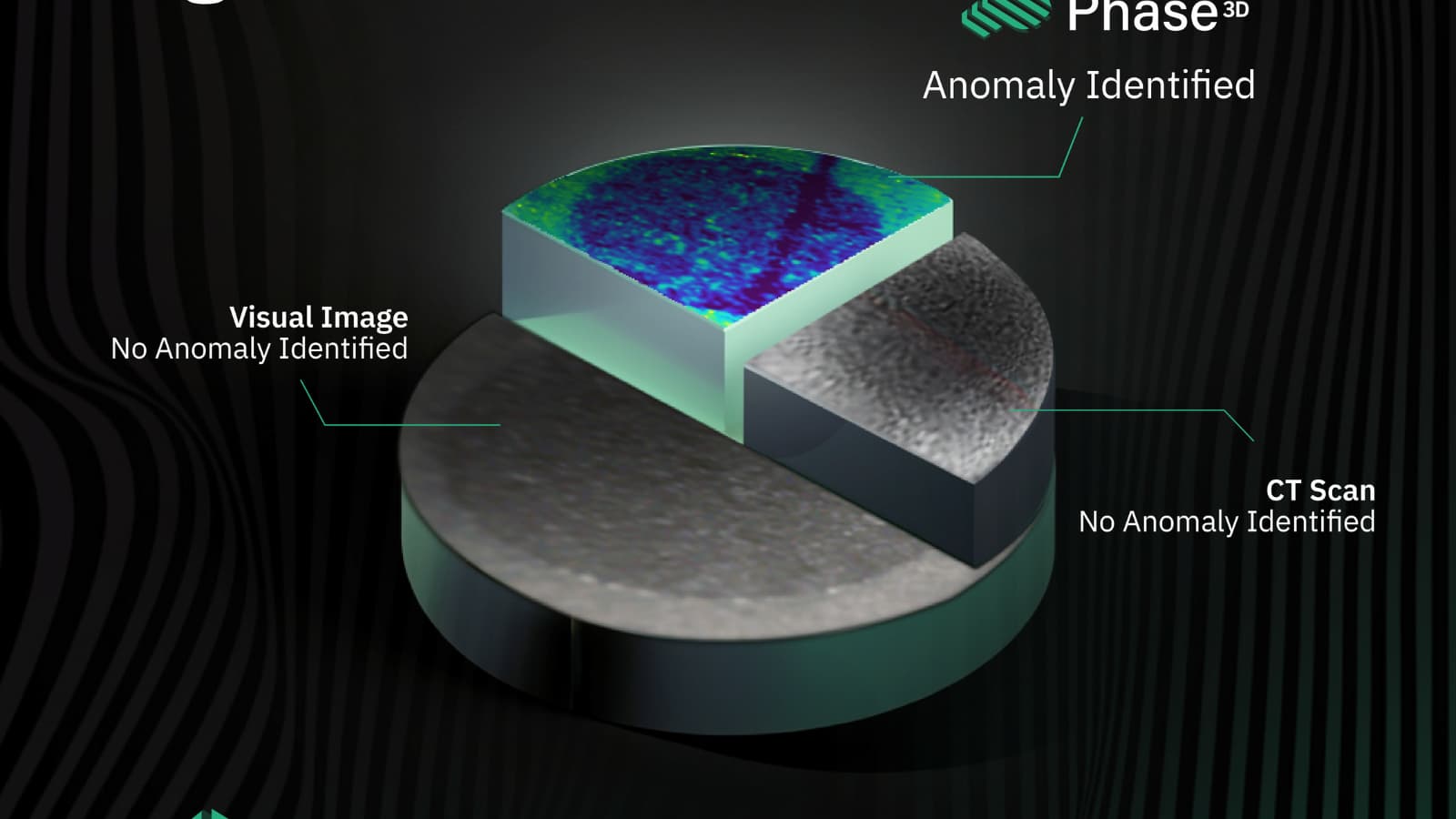

Eliminating the Risks of Visual Image Analysis in Additive Manufacturing with Fringe Inspection™

Phase3D Successfully Completes $1.25M Air Force Cold Spray Quality Inspection Product Deployment

Webinar: An Introduction to Phase3D - The Importance of Real In-situ Inspection

Spotlight on Innovation: Dr. Niall O’Dowd Named Finalist for 2025 Chancellor’s Innovation Award

The Digital Nature of Additive Manufacturing Is a Double-Edged Sword

Phase3D Expands into Japanese Market Through Strategic Partnership with TNSC

Ensuring Excellence: The Critical Importance of Validation and Certification in AM Production

Examining Recoater Damage: How Alloyed is Addressing the Challenge

The Future of Aviation with Additive Manufacturing Requires In-Situ Inspection