Partnering for Precision: Phase3D and Argonne National Laboratory Advance Metal 3D Printing

Phase3D Partners with Materialise

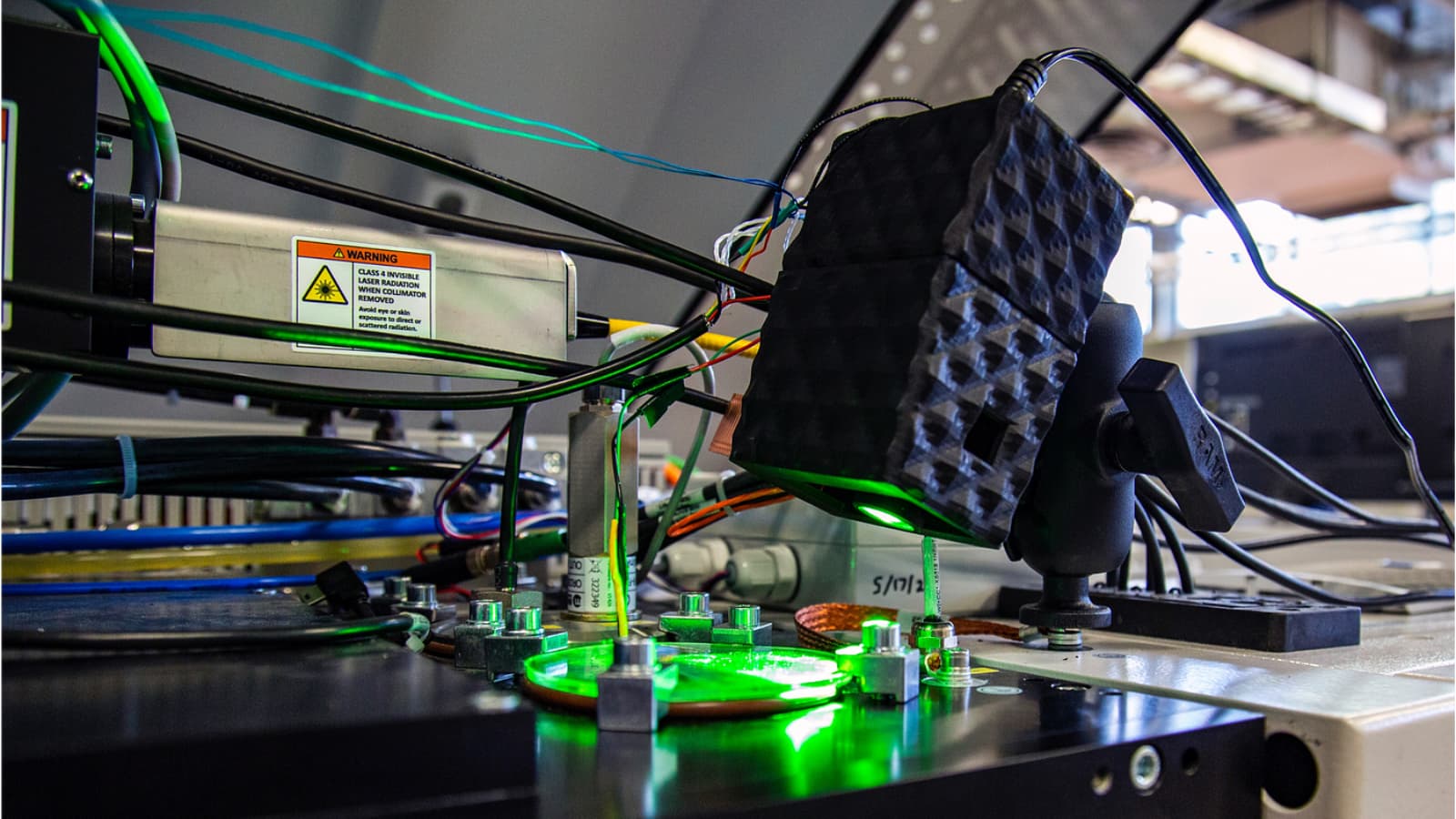

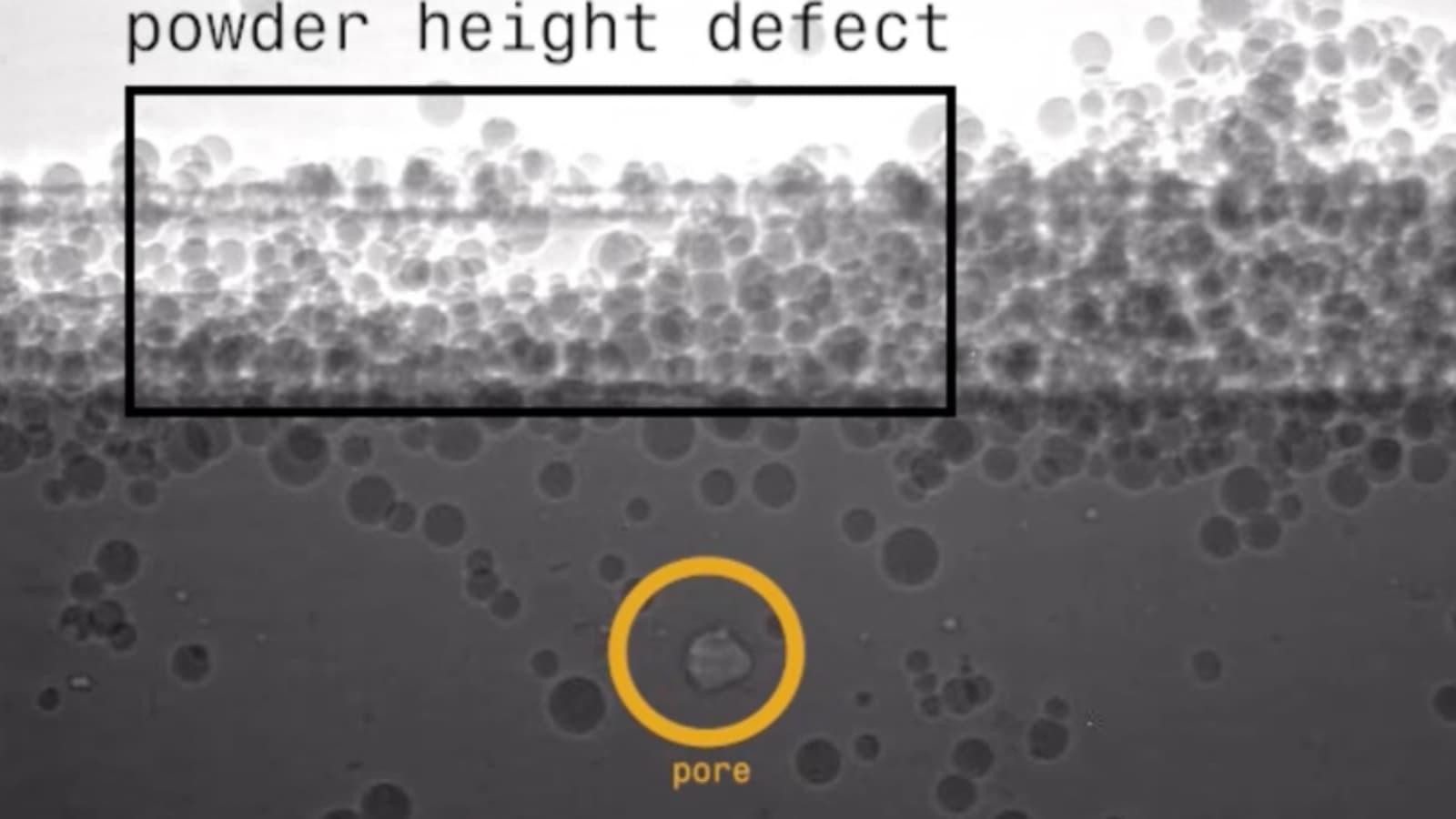

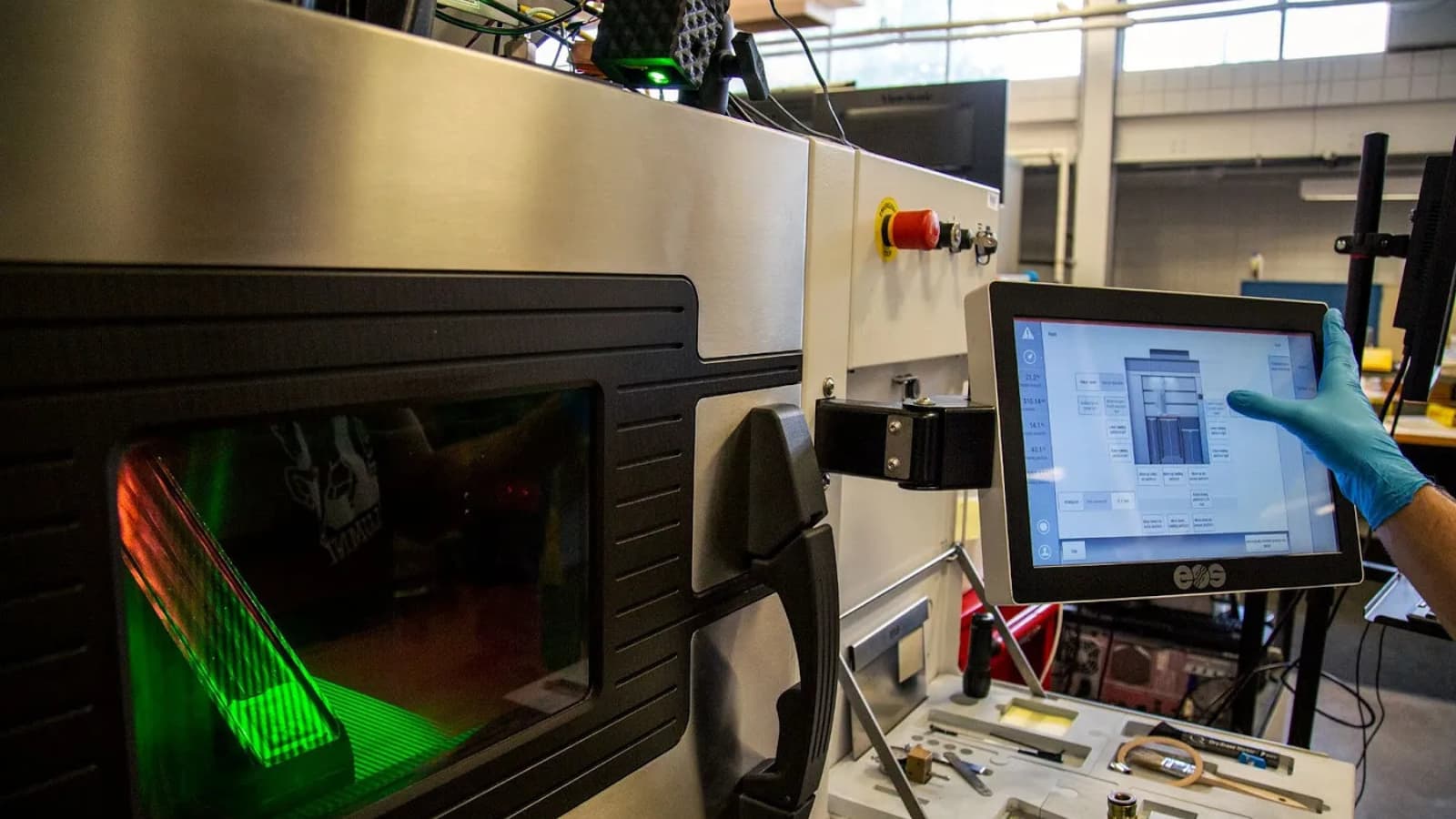

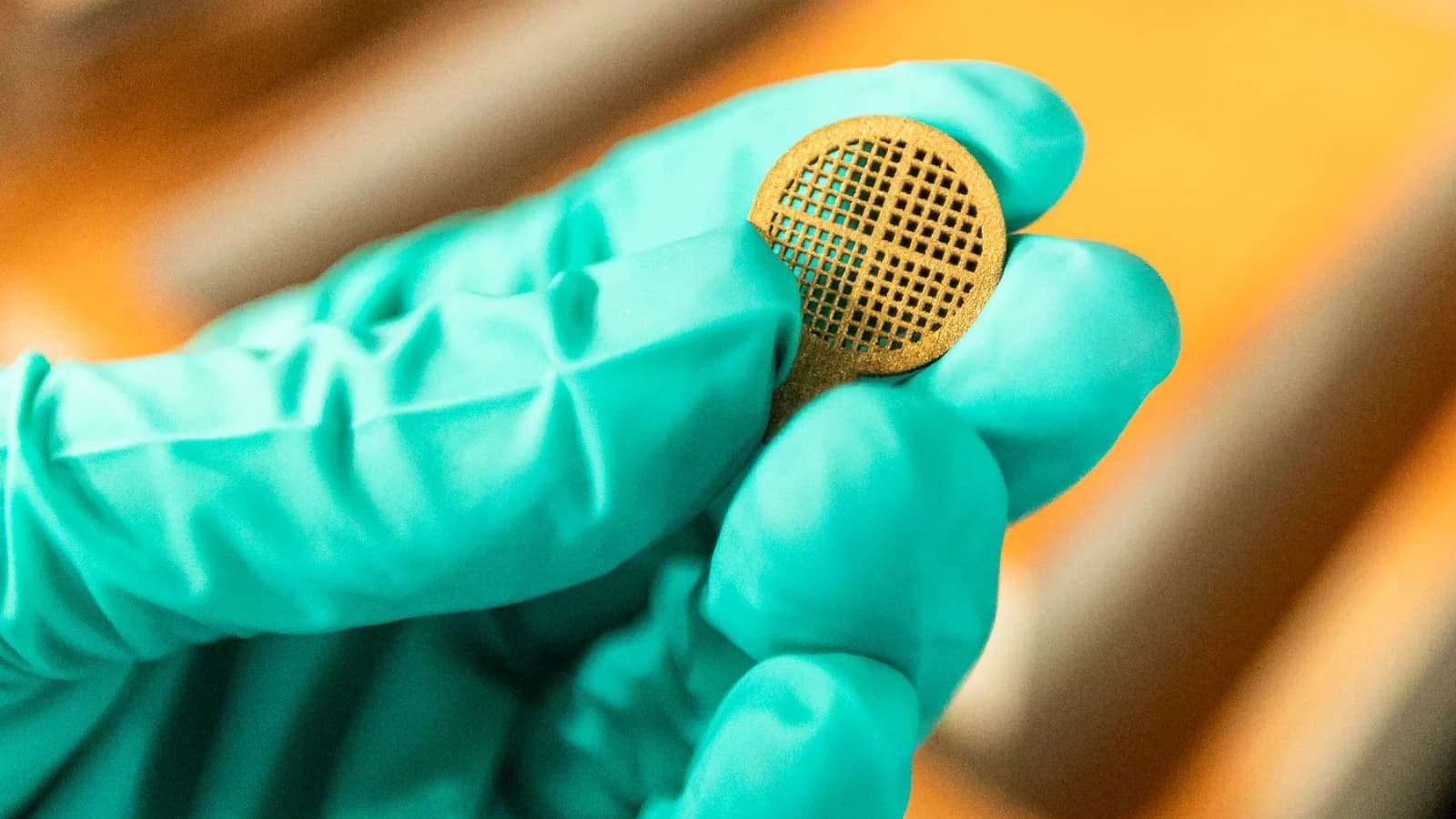

Linking Height Irregularities to Gas Porosity via Synchrotron X-rays

Phase3D Launches Early Adopter Program for 3D Printing Inspection

Phase3D Completes Collaboration with Oak Ridge National Lab

Phase3D Wins Air Force Innovation Open Call

Additive Monitoring Systems is now Phase3D

NASA Selects Additive Monitoring Systems for In-Situ Manufacturing

Driving Sustainable Innovation in Additive Manufacturing with the U.S. Department of Energy

US Air Force Contracts Chicago Startup for Additive Manufacturing Monitoring